Permanent Antistatic Additives

Permanent Antistatic Agent: High-efficiency Antistatic Solution

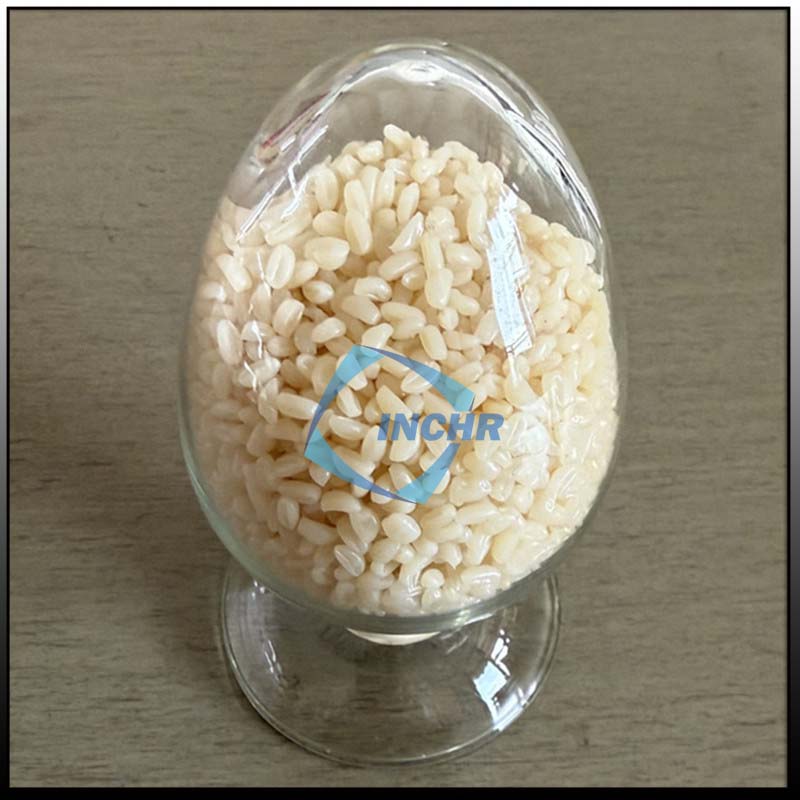

INCHR® Permanent Antistatic Agent is a copolymer composed of polyether, polyester, and polyamide blocks, in light yellow, natural, or translucent granular form. As a functional additive, it can reduce the resistivity of plastics and achieve long-term electrostatic protection. It is also called permanent ESD concentrate.

INCHR® Permanent Antistatic Agent has strong compatibility and is compatible with a variety of polymers such as low-density polyethylene (LDPE) and polypropylene (PP), as well as functional additives such as antioxidants and flame retardants.

This antistatic agent has permanent and immediate antistatic properties, is minimally affected by relative humidity, will not frost or migrate on the product’s surface, can be directly dry-mixed or compounded, and is suitable for colored products. By adjusting the dosage and compounding with the matrix, the product’s surface resistivity can reach 10⁸ – 10¹¹Ω.

INCHR@ permanent antistatic agent has various applications: Used for the production of antistatic films such as LLDPE, TPU, PP; Suitable for antistatic sheets such as HIPS, ABS, POM, HDPE; Can be used for various injection molded products such as PC, PBT, nylon; Used for PA6 yarn (BCF) spinning.

INCHR® Permanent Antistatic Agent: Three Structures, Excellent Performance

Long-chain polyether amide type

This permanent antistatic agent is based on a self-made long-chain polyetheramide elastomer, compounded with alkali metal sodium salt and lithium salt, and evenly dispersed in the material. It can not only achieve a surface resistivity of 2×10⁷Ω/sq but also has an elongation at break of over 600%. Its antistatic performance does not decay due to rinsing, it has strong mechanical stability, and its long-term protection advantage is significant.

Block elastomer type

By forming a polymer network structure through block elastomers, the resistivity of the material is quickly reduced, and instant and lasting static dissipation is achieved. Even in extremely low humidity environments, it can still stably exert antistatic effects and is widely applicable to various plastic modification needs such as PA, ABS, PC/ABS, etc.

Polyurethane type

Break through the surface migration mechanism of traditional antistatic agents, deeply integrate with polyurethane materials, synchronize antistatic performance with material life, no fear of surface wear and long-term use attenuation, and give polyurethane materials stable, overall permanent antistatic ability.

INCHR® Permanent Antistatic Agent: Four Core Performance Advantages

1. Long-lasting and Stable Antistatic: Based on the special molecular structure and high matrix compatibility, the antistatic effect is long-lasting and does not reduce the performance due to long-term use; it can still maintain stable performance in harsh environments such as high temperatures and high humidity.

2. Non-migration is more secure: it will not migrate or seep out from the substrate, avoiding the attenuation of antistatic performance and eliminating the risk of pollution in the surrounding environment.

3. Flexible color matching: the product is light-colored or transparent, perfectly adapted to the color formula, and meets the needs of diversified colors.

4. Wide range of material compatibility: highly compatible with a variety of polymers such as polyethylene, polypropylene, polystyrene, and rubber materials such as styrene-butadiene rubber, nitrile rubber, and EPDM, with rich application scenarios.

High-Transparency Antistatic Solution: INCHR®T Series Antistatic Agent

• INCHR®120T: A permanent antistatic solution customized for MABS, which effectively eliminates hidden dangers of static electricity and firmly maintains the high transparency of the material.

• INCHR®820T: Adapted to transparent polyester TPU, it has almost no effect on the mechanical properties of the resin after addition, and gives a stable surface resistivity.

• INCHR®204T: Focusing on PET resin, especially suitable for PET transparent sheets, ensuring electrostatic protection and visual transparency. In addition, for materials such as GPPS, PP, and PVC, transparent antistatic customized formulas are provided.

Outstanding core advantages

• High transparency: As a high-molecular crystalline polymer, it destroys its own crystallization after dispersion, and has a refractive index similar to that of the substrate. It is almost invisible after addition.

• Strong compatibility: It is fully compatible with transparent resins, evenly dispersed, and does not interfere with the basic properties and light transmission effects of the material.

• Wide applicability: covers all kinds of transparent and light-colored plastic products, and can be safely used in high-requirement fields such as medical devices and food packaging.

INCHR® Permanent Antistatic Agent Usage Guide

When using INCHR® permanent antistatic agent, the key is to determine the addition amount according to the processing conditions, product form, and antistatic requirements. The addition method is flexible. It can be directly added to the resin for processing, or it can be made into an antistatic masterbatch and mixed with blank resin. The latter is easier to achieve uniform dispersion.

Due to the differences between different models of INCHR® permanent antistatic agent, be sure to refer to the corresponding product manual before use. When selecting this antistatic agent, it is necessary to comprehensively consider the performance, additional amount, and impact on other components.

If the antistatic effect does not meet expectations in actual production, the addition amount can be appropriately increased, but be wary of the negative impact of excessive addition on the mechanical properties of the material. In addition, adjusting process parameters such as processing temperature and time can also help optimize the antistatic effect.properties of the product, and cost. At the same time, small-scale tests can be carried out to ensure its effect and compatibility in specific applications.