Conductive Compound

Excellent and controllable conductive performance

Conductive compound refers to modified materials composed of conductive fillers, base resins, and special additives through physical or chemical methods that have good conductive properties.

Conductive fillers include carbon black, CNT, conductive metal powder, carbon fiber, etc., and the base resin matrix includes plastic, rubber, etc. The conductivity value of the material can be adjusted by the content of conductive fillers.

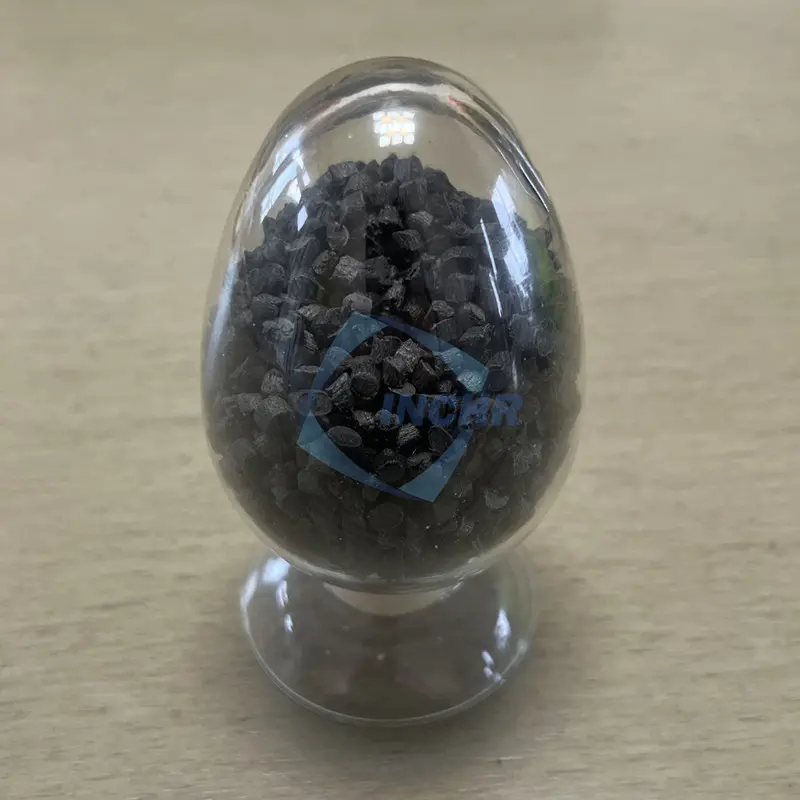

A conductive masterbatch is a kind of conductive compound. Conductive fillers (such as carbon black, metal powder, etc.) are evenly dispersed in carrier resin (usually high molecular polymers) and made into a functional masterbatch with high conductive properties through a specific process.

The role of conductive masterbatch is to facilitate the uniform addition and stable performance of conductive properties in subsequent products, and it is easy to use. It can be directly mixed with the base resin in a certain proportion, reducing the complex process of on-site preparation of conductive fillers and improving production efficiency.

Conductive masterbatch can ensure the consistency of conductive properties. Since the conductive filler has been evenly distributed in the masterbatch, it can provide the stability and uniformity of the conductive properties of the final product.

The conductive compound is a type of lightweight, high-strength, anti-corrosion, low-cost, and easy-forming material. Compared with aluminum alloy, it has irreplaceable advantages in terms of either performance or cost (especially for complicated parts).

Hence it will have wide and optimized prospects. In the electric industry, replacing commonly used metal shells or parts with conductive compounds is becoming a trend.

The EMI shielding effect is mainly achieved by reflecting electromagnetic waves on the material surface (especially the frequency below 10GHz) and absorbing when wave penetrating materials, the total efficiency of any EMl shielding material is equal to the sum of reflection and absorption.

- The shielding effect of high-frequency electromagnetic waves mainly depends on reflection, and the shielding effect of low-frequency electromagnetic waves mainly depends on absorption.

- The stronger the conductivity of the material, the stronger the reflection effect will be taken; the stronger the magnetic properties or the thicker the thickness of it (related to the depth of the skin), the stronger the absorption effect will be taken.

- Metal is the most widely used EMI shielding material, Aluminum alloy, and other commonly used metal materials mainly rely on reflection, but almost no absorption.

- INCHRConductive compound is often prepared with high-performance engineering plastics (such as ABS+PC, PPO, PPA, PPS, etc.) as base material, it has very good corrosion resistance, processability, and low production energy loss.

- After a salt spray exposure test (360 hours, 5% NaCl solution, 35 degrees,95% relative humidity [ASTM B117] ), the conductive compound has strong corrosion resistance, it is an ideal choice for outdoor harsh environments.

- The density of INCHR Conductive compound is only 1/4 of common metals, even half of aluminum’s (the density is 1.2-1.4g/cm, aluminum density is 2.7g/cm3).

- Due to the low density and the possibility can be processed into a thin wall structure (about 1.0mm, half of aluminum casting), the weight of the final finished part was reduced by 755%.

- Although the thickness is greater than the stainless steel parts, the overall weight can be reduced by 50% after the replacement.

Application Areas

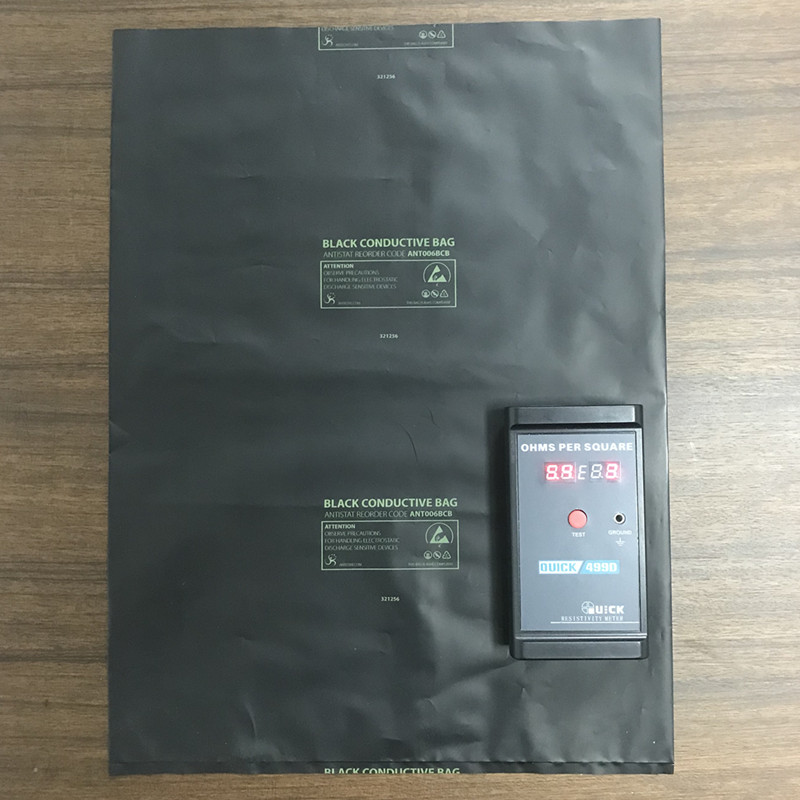

- New shielding materials: can limit the energy transfer of electromagnetic waves and reduce the magnetic field strength or radiation intensity.

For example, metal foil and metal fiber are added to plastics to make conductive plastics for electromagnetic wave shielding; ferrite powder is compounded with resin and made into shielding parts of various shapes by hot pressing, or made into surface absorption coatings by coating to meet higher requirements for shielding and stealth materials.

- Electrical engineering: widely used as inner and outer semiconductor layers of high-voltage cables and outer semiconductor layers of low-voltage cables.

- Electronic devices: such as flexible strain sensors, are used to detect human finger movements, facial muscles, voice recognition, physiological signals, and temperature changes of the human body.

- Wearable devices: used to manufacture directional light-emitting electroluminescent devices with excellent mechanical properties.

The devices have higher brightness and directional light-emitting characteristics and have great potential in smart displays and optical signal flexible electronic products for smart wearable devices.

- Energy storage field: used in supercapacitors, lithium-ion battery casings, etc.

- Other fields: Rubber-type conductive compounds have good airtightness and are often used as sealing materials.

They are also often used in electronic and electric vacuum technologies to overcome some shortcomings of soldering. They can also be used in biofuel cells, optoelectronic devices, nanogenerators, and other fields.