Introduction Of Graphene

- Graphene is a two-dimensional crystal composed of carbon atoms with sp2 hybrid orbitals forming a hexagonal two-dimensional carbon nanomaterial in a honeycomb lattice. Graphene has excellent optical, electrical, and mechanical properties and has important application prospects in materials science, micro-nano processing, energy, biomedicine, and medical delivery. It is considered a revolutionary material in the future.

- Graphene is a two-dimensional crystal composed of carbon atoms with sp2 hybrid orbitals forming a hexagonal two-dimensional carbon nanomaterial in a honeycomb lattice. Graphene has excellent optical, electrical, and mechanical properties and has important application prospects in materials science, micro-nano processing, energy, biomedicine, and medical delivery. It is considered a revolutionary material in the future.

- Graphene is very widely used in modified plastics nowadays, the nylon nanocomposite material obtained by uniformly dispersing graphene in the Nylon 6 system can greatly improve many properties of Nylon 6, such as thermal properties, mechanical properties, flame retardancy, and barrier properties, thereby improving the performance of nylon nanocomposite materials.

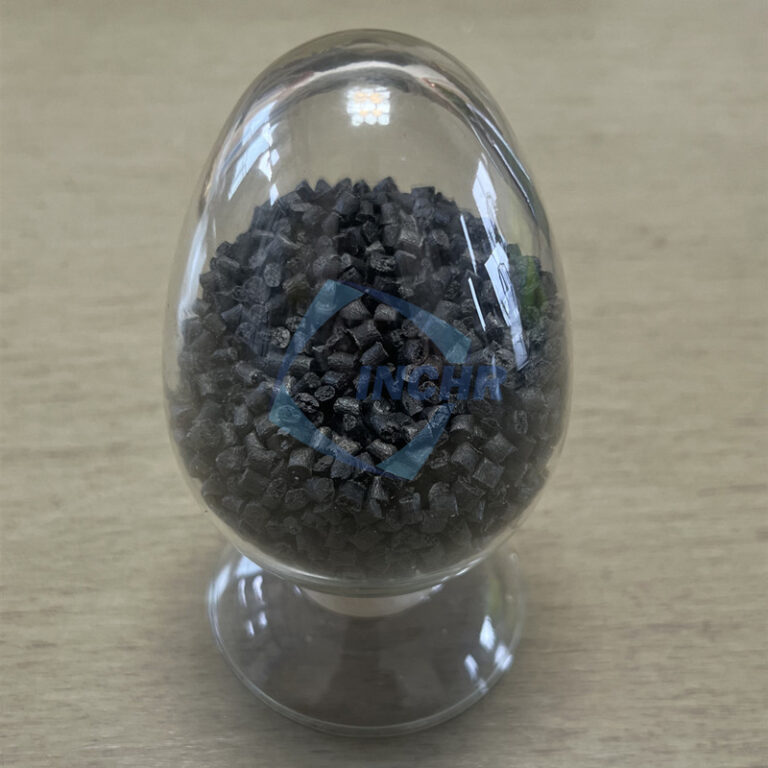

Introduction Of Graphene Reinforced Nylon

- Graphene reinforced nylon is a modified plastic which is a compound composed of graphene and nylon resin. Graphene is a two-dimensional crystal structure composed of carbon atoms. It has high electrical and thermal conductivity and can improve the electrical and thermal conductivity of fibers. Graphene also has high-strength properties, which can increase the durability and strength of nylon fibers.

- The preparation method of graphene reinforced nylon can be achieved by mechanical mixing, sol-gel impregnation, and chemical reduction. Among them, sol-gel impregnation is a commonly used preparation method, which can effectively incorporate graphene into the nylon matrix and maintain its physical and chemical properties. This makes graphene nylon have broad applications.

- Graphene reinforced nylon is a thermally conductive graphene reinforced plastic on the market. Compared with the thermal conductivity of ordinary nylon resin, which is about 0.3W/m-K, the heat transfer performance of graphene nylon is improved by 10 to 50 times. It efficiently conducts heat to a heat sink or surrounding air, extending product life and enhancing design freedom. Its high thermal conductivity can provide a heat transfer rate of 1.8W/mK, enabling a large amount of heat transfer, and providing new possibilities for part design and metal substitution.

- Graphene reinforced nylon can be made stronger by adding a small amount of glass fiber reinforcement. This not only improves the operating efficiency and life span of graphene nylon but also reduces operating temperatures and improves the electrical efficiency of the packaged motor, resulting in more usable power and torque. In addition, the use of thermally conductive nylon can reduce current consumption, speed up response time, and extend the service life of the equipment.

- It is worth mentioning this graphene reinforced plastic has a comparable expansion coefficient to that of metals, so it can be produced with a coefficient of linear thermal expansion (CLTE) close to that of many metals. This gives graphene nylon an advantage in replacing metal materials. In short, the emergence of graphene nylon has brought more design freedom to the industry and has huge potential in improving product performance and improving work efficiency.

Characteristics Of Graphene Reinforced Nylon

- After adding thermal conductive additives, the thermal conductivity of graphene reinforced plasticcan reach 1.8W/mK.

- High rigidity and high bending modulus.

- High flow and good injection molding performance.

- Resistant to stress cracking.

- Good fluidity, easy to form, suitable for forming ultra-thin products.

- Good chemical resistance and UV varnish resistance.

- Low warpage and high flatness.

Applications Of Graphene Reinforced Nylon

- In the field of electronic devices, graphene reinforced nylon can be used to manufacture products such as flexible electronic devices, conductive fibers, and sensors.

- In the field of aerospace, graphene reinforced nylon can be used to manufacture aviation materials, conductive fibers, and radiation protection materials.

- In the field of textiles, graphene reinforced plastic can be used to manufacture smart textiles, anti-static fibers, and anti-UV fibers.

The graphene reinforced plastic was developed by our team which uses special graphene dispersion and reinforced technology and uses a reactor to polymerize graphene and nylon 6/66. The new graphene reinforced plastic not only has wear resistance, tensile strength, impact resistance, chemical resistance, and low friction Coefficient and self-lubricating properties have been greatly improved, and it also has antibacterial, dustproof, antistatic, and far-infrared thermal insulation properties; and graphene only needs to be added in trace amounts, and the cost is relatively low.