Anti Static Compounds

Antistatic “smart” selection, INCHR defines a new level of protection with customization

At a time when the demand for electrostatic protection is becoming increasingly refined, INCHR has become a benchmark company for anti-static compound solutions in the industry with its technological advantages and product innovation. Its customized anti-static compounds have permanent anti-static properties and can accurately control different surface resistance values to provide long-term and reliable electrostatic protection for electronic components, precision instruments, packaging, and transportation.

From material selection to process adaptation, INCHR demonstrates all-round competitiveness. More than ten basic materials and alloy substrates such as ABS, PC, PP, HDPE, LDPE, HIPS, GPPS, POM, TPE, TPU, PBT, Nylon, etc., cover multiple application scenarios; full process specifications such as injection molding, extrusion, blow molding, etc., ensure that the product seamlessly connects to various production processes; flexible coloring performance breaks the appearance limitations of traditional anti-static compounds. INCHR takes “customization” as the core deeply integrates technology into products, creates highly adaptable and high-performance anti-static solutions for customers, and leads the industry into a more efficient and intelligent protection era.

Common transparent antistatic compounds from INCHR

INCHR@Transparent Antistatic Compounds are ESD compounds that add permanent antistatic agents or other functional ingredients to transparent resins to make them antistatic and transparent.

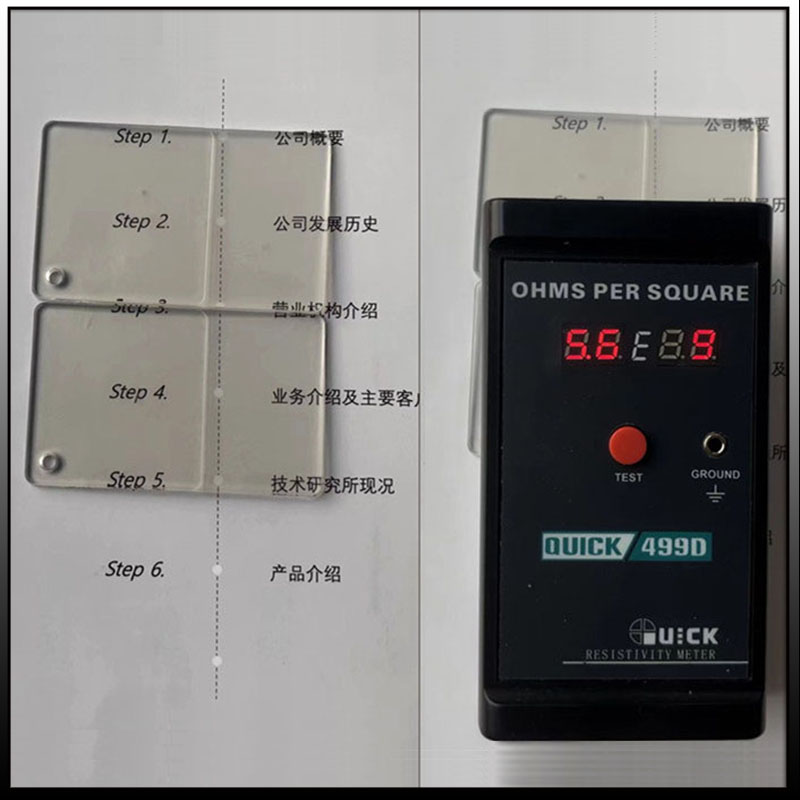

Transparent ABS antistatic compound

This antistatic compound is based on MABS resins such as LG 558A, and Toray 920-555. The surface resistivity is usually between 10⁶-10¹¹Ω, which can effectively prevent the accumulation of static charges and avoid static damage to electronic components. It has high transparency and can be used for products that require a transparent appearance, such as lenses, containers, and electronic and electrical parts. Transparent ABS antistatic compounds retain the original good impact resistance, dimensional stability, easy flowability, low water absorption, chemical resistance, and other comprehensive physical and mechanical properties of ABS. Transparent ABS antistatic compounds are mainly used in the electronic and electrical industry and products in the medical equipment field that are sensitive to static electricity and require a transparent appearance.

Transparent TPU antistatic compound

Transparent TPU antistatic compounds are a thermoplastic polyurethane composite material with special properties. It has excellent antistatic properties, and its surface resistivity is usually between 10⁶-10¹¹Ω. It can quickly release static electricity and effectively prevent static electricity accumulation. High transparency. It has good mechanical properties, elasticity, toughness, wear resistance, chemical resistance, and low-temperature resistance. Transparent TPU antistatic compounds are mainly used to manufacture transparent packaging materials for electrostatic sensitive products, as well as medical equipment shells, catheters, infusion bags, etc., to avoid static electricity adsorption of dust and bacteria, affecting the performance and hygiene of medical equipment.

Transparent GPPS antistatic compound

Transparent GPPS (general polystyrene) antistatic compound is a high-performance material. Its surface resistivity can reach about 10⁸ – 10¹²Ω, which can maintain the original high transparency of GPPS and has a high transmittance to visible light. Transparent GPPS antistatic compound has good physical properties. It inherits some basic characteristics of GPPS materials, such as lightweight, good rigidity, and easy processing and molding. It can be made into various products through injection molding, extrusion, and other processes.

Transparent PVC antistatic compound

The transparent PVC antistatic compound is a special polyvinyl chloride compound that has antistatic ability while maintaining transparency. The general surface resistivity is around 10⁸ – 10¹²Ω. It allows the most visible light to pass through and can be used to manufacture products that require a transparent appearance, such as transparent packaging, display items, etc. This antistatic compound retains the good flexibility of PVC and is easy to process and shape. It can be made into various products through various processing methods such as extrusion, injection molding, and blow molding.

Core advantages of INCHR@Polyether amide-based antistatic compounds

Excellent and long-lasting antistatic performance

Polyetheramide-based antistatic compounds can be used as permanent antistatic masterbatches, which can build a stable conductive network inside the material so that static electricity on the surface of the material can be quickly conducted and dissipated. The antistatic effect is remarkable, and this performance is not affected by the passage of time and surface wear. In the fields of electronic equipment housing manufacturing and electrostatic-sensitive plastic product production, it can effectively prevent static electricity from damaging equipment or products, and ensure product quality and performance stability.

Excellent comprehensive mechanical properties

This compound integrates the characteristics and advantages of polyether and polyamide and has the dual characteristics of high strength and high toughness. Among them, the polyamide hard segment provides strength and rigid support for the material, and the polyether soft segment gives the material good flexibility and elasticity. Such excellent mechanical properties enable it to withstand greater mechanical stress in various application scenarios, effectively reduce the risk of breakage and damage, and is suitable for the manufacture of parts, sheets, films, and other products with strict requirements on mechanical properties.

Good molding and processing performance

INCHR@ polyether amide-based antistatic compounds have excellent processing adaptability and can be easily adapted to common processing technologies such as extrusion, injection molding, and blow molding. During the processing, the material shows good fluidity and can fully and evenly fill the mold. The dimensional stability of the molded product is excellent, which can accurately meet the processing requirements of various complex shapes, greatly improving production efficiency and product precision.

Flexible and diverse appearance and colorability

Compared with traditional antistatic materials (mostly black particles, the color of the finished product is limited and the problem of carbon powder falling off easily occurs), INCHR@ polyether amide-based antistatic materials use transparent or light yellow antistatic agents to achieve antistatic function. Since it does not contain carbon components, it can be flexibly colored into primary colors, black, or other colors according to actual needs, fully meeting the application scenarios with special requirements for product appearance color, and broadening the application range of the material.

Unique biocompatibility (some products)

If polyether amide-based antistatic compounds are prepared with bio-based raw materials, they have good biocompatibility. For example, long-chain polyether amide synthesized from bio-based dibasic acids, diamines, and other raw materials has great application potential in the biomedical field and can be used in medical device manufacturing, tissue engineering scaffold construction, etc. At the same time, it can also be used as food packaging materials to achieve functional applications of materials while ensuring food safety.

Excellent water resistance stability

The special structure of polyether amide gives the compound low water absorption and good water resistance. Compared with ordinary antistatic compounds, INCHR@ polyetheramide antistatic compounds can still maintain good performance stability in humid environments or in contact with water, and are not easily degraded due to water absorption, ensuring the long-term reliable use of the material in complex environments.