Introduction Of Antistatic Agent For Plastics MABS

Introduction Of Antistatic Agent For Plastics MABS

- Antistatic agent for plastic transparency is an ESD additive designed for transparent polymers. It can ensure the transparency of ESD polymers and has an antistatic function. Commonly used antistatic agents for plastic transparency are based on MABS, PP, TPU, GPPS, PMMA, PVC, PETG, and PCT.

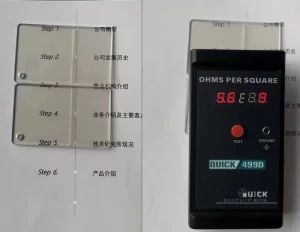

- 120T is a permanent, internally added antistatic agent for plastic transparent ABS. It can prevent static electricity problems caused on the surface of transparent ABS and has good compatibility with transparent ABS, such as LG 558A, Toray 920-555, etc. It can be processed by injection and extrusion. The recommended dosage level is 10%-25%wt. The resistance value of ESD polymer that contains 20 percent of 120T is about 10E8 Ohms.

- 130T is an antistatic masterbatch based on an antistatic agent for plastic. The ESD concentrate is suitable for ESD polymers with a resistance value of 10E10~10E11 Ohms. It is directly dry-mixed at a ratio of about 10% and does not require compounding.

- 120T and 130T are suitable for ESD transparent packaging sheets, ESD transparent packaging films, and ESD transparent injection molded parts. The main applications are transparent IC chip trays and transparent IC containers in the semiconductor packaging industry (such as Samsung Electronics and SK Hynix).

- Antistatic agent for plastic transparency has low dependence on humidity, which ensures that the surface resistivity of the end product changes little in different humidity environments.

Features Of Antistatic Agent For Plastic MABS

- Maintaining high transparency, while playing an antistatic role, has little effect on the light transmittance of MABS resin. It is suitable for products with high transparency requirements such as optical devices and transparent plastic products, and can ensure that the products are clearly visible without affecting the visual effect.

- Small impact on the performance of the base material. In the process of compounding an antistatic agent for plastic, it will not have adverse effects on the basic properties of the material, such as mechanical properties, thermal properties, chemical properties, etc. This ensures that the product can still maintain the original performance characteristics and quality standards after adding the antistatic agent.

- Acts immediately and provides the long-term antistatic effect. Both 120T and 130T are Not hygroscopic ionomer resin which are permanently antistatic additives for plastics.

- 120T is favorable for compounders and can be processed by injection, extrusion, and blow molding.130T can be directly used in dry blending and is favorable for sheet or film manufacturers.

- Antistatic agent for plastic transparent has Low addition amount, more cost-effective than buying ESD polymers or antistatic masterbatches.

Packaging And Storage

Packaging And Storage

- Each bag is 25kg, the outer packaging is a composite bag, the inner packaging is a vacuum aluminum foil bag, and it should be stored in a cool and ventilated warehouse. Rain and water immersion are strictly prohibited.

- The antistatic agent for plastics can be stored in their original packaging for at least 12 months without losing their properties. After opening, use immediately. Keep closed when not in use. In case this product absorbs moisture, drying at 85 ºC for 3 hours under a vacuum is required before use.

- Use immediately after opening, and keep closed when not in use. The antistatic agent for plastics is hygroscopic antistatic additives, to minimize exposure to moisture, any remaining material should be hermetically sealed in a barrier package immediately after use. The bag has as much air removed as possible before sealing. A vacuum to pull out the air can be used to assist in this process. To reuse the remaining material that has been hermetically sealed, the material should be dried under a vacuum at 80-95°C for several hours.