Introduction Of PC/ABS ESD Polymer

Introduction Of PC/ABS ESD Polymer

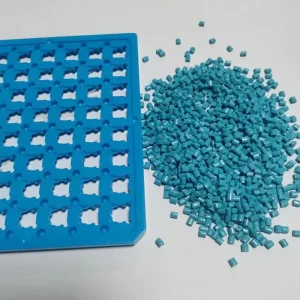

● ESD PC/ABS compound is an ESD polymer that combines polycarbonate (PC) and acrylonitrile-butadiene-styrene copolymer (ABS) and adds a permanent antistatic agent, suitable for injection molding and extrusion. The surface resistivity of the compound ranges from 10^8-10^11 Ohms/sq.

● 2100AN is an ESD polymer of PC/ABS alloy. This material combines the excellent properties of PC and ABS, with high impact resistance, excellent heat and weather resistance, dimensional stability, chemical resistance, good processing fluidity, and high fluidity.

● 53AS is an ESD polymer based on ABS (acrylonitrile-butadiene-styrene terpolymer) resin, which is made of an ESD compound with antistatic properties by adding specific permanent antistatic agents, conductive fillers or using other special treatment methods, colorable.

Features Of PC/ABS ESD Polymer

● High impact resistance: ESD PC/ABS compounds have high impact resistance and can withstand large impact forces while maintaining good mechanical properties and impact strength.

● Excellent heat and weather resistance: The ESD polymer has good heat and weather resistance, and can maintain the stability and durability of the material under high temperatures and harsh environments.

● Dimensional stability: ESD PC/ABS compounds have good dimensional stability and can maintain dimensional accuracy under different temperature and humidity conditions.

● Chemical resistance: It has good chemical resistance and can resist the erosion of certain chemicals, maintaining the stability and service life of the material.

● Good processing fluidity: The ESD polymer has good processing fluidity, is easy to process, and is suitable for various processing methods such as injection molding.

● High fluidity: It has high fluidity is easy to process and is suitable for making thin-walled products and other application scenarios that require good fluidity.

Applications Of PC/ABS ESD Polymer

Applications Of PC/ABS ESD Polymer

● ESD PC/ABS composite materials are used for anti-static turnover boxes, IC and LCD trays, IC packaging, chip carriers, film bags, etc. Used in the production and electric field of precision electronic components such as integrated circuits, chips, sensor sheaths, etc. in electronic products.

● Used in anti-static plastic shells and structural parts of explosion-proof products such as coal mines, tankers, oil fields, dust, and combustible gases to prevent static electricity from causing sparks and explosions.

● The ESD polymer is widely used in the shells, substrates, connectors, and other components of electronic products such as computers, communication equipment, monitors, and printers to prevent static electricity from damaging sensitive components.

● Can be used for surgical instruments, diagnostic equipment, medical instrument shells, etc., to reduce the impact of static electricity on equipment and patients, and ensure the accuracy and safety of equipment operation.

● Used in aerospace, chemical, petroleum, textile, and other industries to manufacture various anti-static equipment and components, such as parts in aerospace equipment, containers and pipelines in chemical production, and anti-static work clothes in the petroleum industry.