Introduction Of Carbon Fiber Reinforced ABS

Introduction Of Carbon Fiber Reinforced ABS

- Carbon fiber reinforced ABS is a composite material with acrylonitrile-butadiene-styrene copolymer (ABS) as the matrix and carbon fiber added for reinforcement. This carbon fiber thermoplastichas electrical conductivity, and the content of carbon fiber determines the strength of the electrical conductivity.

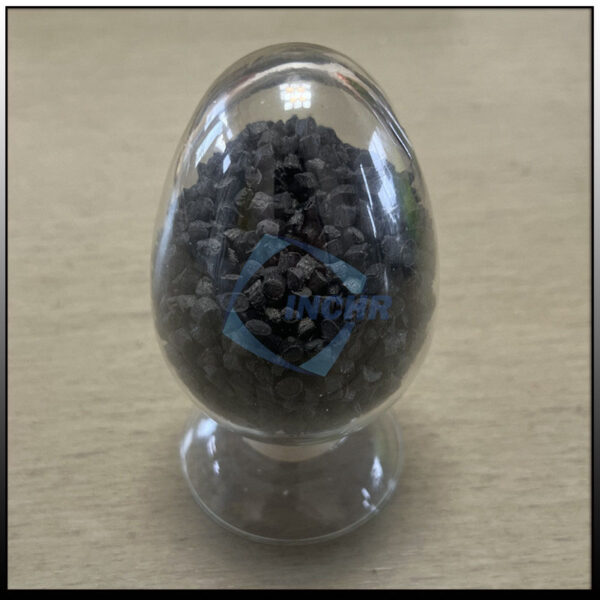

- 757CF15 is one of the carbon fiber reinforced thermoplastic series which is 15% carbon fiber filled. The compound is a carbon fiber thermoplasticspecially designed for injection molding. Carbon fiber-reinforced plastic is lighter than metal, effectively reducing product weight by 15% to 40%.20% carbon fiber,25% carbon fiber, and 30% carbon fiber carbon fiber-reinforced pellets are optional.

- Carbon fiber reinforced ABS features high mechanical strength and good heat resistance, the long-term use temperature can reach 80°C, and it maintains good mechanical properties under thermal conditions. At the same time, carbon fiber reinforced thermoplastic ABS has excellent mechanical properties and dimensional stability.

- Excellent anti-static and conductive properties. Due to the conductive properties of carbon fiber, this carbon fiber reinforced ABS can effectively prevent the accumulation and adhesion of static electricity and also has good electrical conductivity. Different contents of carbon fiber filling can be used in conductive occasions.

- Good chemical resistance. Due to the use of special additives, carbon fiber reinforced ABS shows high stability in terms of chemical corrosion and can withstand the erosion of various solvents and corrosive liquids.

How To Improve The Dimensional Stability Of Carbon Fiber Reinforced ABS

- Select suitable ABS resin and necessary pretreatment

Ensure the quality of the ABS resin and carbon fiber used is stable, including its molecular weight distribution, purity, and other indicators. Select ABS resin with a low thermal expansion coefficient and good matching with carbon fiber to reduce the dimensional instability caused by the difference in the characteristics of the material itself from the source. Carbon fiber reinforced ABS is sensitive to moisture, and the material needs to be fully dried before processing to remove moisture. The presence of moisture will affect the fluidity and molding properties of the material, resulting in unstable product size. The drying conditions are generally 80-90℃ and the time is 2-4 hours, which can be adjusted according to the moisture content of the material and the production equipment.

- Reasonably set the injection molding process parameters

Select a suitable barrel temperature so that the material can be fully melted without overheating and degradation. The barrel temperature of injection molding carbon fiber reinforced ABS is generally between 220-260℃, but the specific temperature needs to be fine-tuned according to the material formula and equipment. Too high a temperature will increase the fluidity of the material, but it will also cause thermal degradation of the material, affecting the performance and dimensional stability of the product; increasing the mold temperature can slow down the cooling speed of the product in the mold, thereby reducing the stress inside the product and improving the dimensional stability. The mold temperature is generally controlled at 75-85℃. For large or complex products, the mold temperature may need to be higher. Select the appropriate injection pressure and speed to ensure that the carbon fiber reinforced ABS can fully fill the mold cavity and does not generate excessive stress. Too high an injection pressure and speed will cause undue stress inside the product, causing the product to change in size after demolding; too low an injection pressure and speed will cause incomplete filling of the product, which will also affect the dimensional stability of the end product.

- Optimize mold design

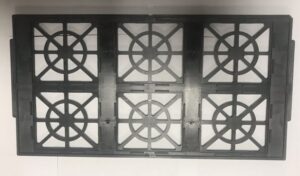

When designing a mold, ensure that the mold cavity structure is reasonable to avoid uneven wall thickness, sharp angles, right angles, and other structures that are prone to stress concentration. Stress concentration will cause the product to change size after demolding, so rounded corner transitions should be used as much as possible to reduce stress concentration. The dimensional accuracy of the mold directly affects the dimensional stability of the end product, so it is necessary to ensure that the dimensional accuracy of the mold meets the requirements. During the mold manufacturing process, high-precision processing equipment and processes should be used to ensure that the dimensional accuracy of the mold meets the design requirements. In addition, a reasonable cooling water channel should be designed to ensure the cooling uniformity of the mold.

- Choose the length and diameter of carbon fiber correctly

Choose carbon fiber of appropriate length and diameter. Generally speaking, shorter carbon fibers are easier to disperse evenly in the ABS matrix, but too long carbon fibers may cause the fluidity of the material to deteriorate. Therefore, it is necessary to select the appropriate carbon fiber length and diameter according to the specific application requirements and processing technology. Surface treatment of carbon fiber can improve the performance and dimensional stability of carbon fiber reinforced ABS. Coupling agents can improve the dispersion of carbon fiber, reduce the agglomeration of fibers, and enable the fibers to better combine with the ABS matrix.

- Use post-processing processes

Annealing the product can eliminate the stress inside the product and improve dimensional stability. The annealing temperature and time need to be determined according to factors such as the size of the end product of the product. Generally, annealing is carried out near the glass transition temperature of the end product, and the time ranges from a few hours to dozens of hours. For some end products with high requirements for dimensional stability, humidity adjustment can be performed. Humidity conditioning treatment can make the product absorb a certain amount of water, thereby reducing the internal stress of the product and improving dimensional stability. The conditions of humidity conditioning treatment need to be determined by factors such as the application environment of carbon fiber reinforced ABS.