A static charge is caused by friction between one surface and another surface and this can be your body, objects, other garments, or even the upholstery of the chair. Surely, you don’t want these charges to accumulate and these charges need to be discharged as quickly as possible. Anti-static materials are schematic to prevent the creation and build-up of triboelectric charging. It occurs when two materials touch and transfer electrons. The antistatic compound is a composite material with long-lasting antistatic properties. It features the ability to inhibit the production of static electricity that can be combined with conductive or dissipative.

Component of antistatic compound | Product Catalog

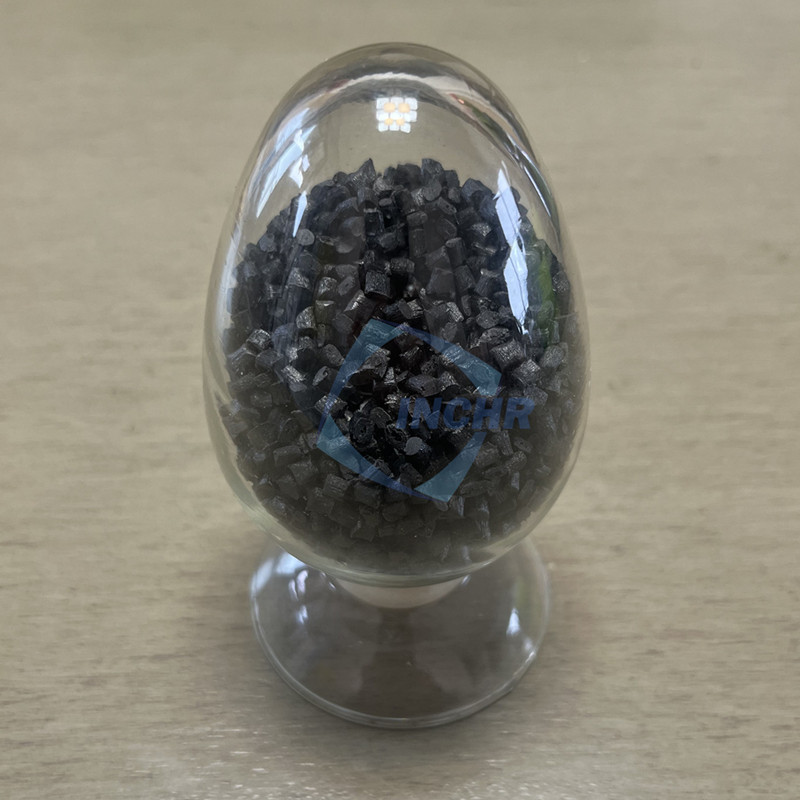

The antistatic compounds are usually composed of a base material (such as PP, PE, PS, PBT, PVC, ABS, PC, Nylon, PET, PEEK, EVA, etc. ) and permanent antistatic additives or conductive fillers. The base material can be a polymer material such as plastic or rubber, and there are many types of antistatic additives, such as conductive carbon black, conductive masterbatch, carbon fiber, permanent antistatic agent, etc. Compared with ordinary antistatic materials, its antistatic additives have more lasting stability and anti-migration.

Working principle of antistatic compound

In simple terms, antistatic compounds are used to prevent any static electricity accumulation or discharge. These conductive fillers are in contact or close to each other, forming a continuous conductive network inside the material. When static electricity is generated on the surface of the material, the static charge can be quickly conducted to the earth or other grounded objects through these conductive pathways, thus avoiding the accumulation of static electricity. For example, antistatic injection molding turnover boxes based on polypropylene (PP) are added with carbon black powder, which can conduct current. When the surface and volume resistivity reach below a certain standard, the antistatic effect can be achieved. The conductive pathways in the antistatic compound with the addition of permanent antistatic agents are more stable and less likely to be destroyed or fail over time.

Necessity of using antistatic compound

- Used in the manufacture of packaging materials for electronic components that are sensitive to static electricity, electronic product housings, etc., to ensure the stability and reliability of electronic equipment.

- Antistatic compounds are used to avoid electrostatic discharge, which can cause electrical interference, fires and short circuits, etc. The material is ideal for high-risk areas where antistatic is critical. These areas include gas stations, hospitals, airports, computer rooms, mobile phone centers, and facilities with high fire risks.

- Antistatic compounds are also used in various products such as soles, mobile phone covers, plastic displays, medical pill dispensers, aerosol equipment, toy parts, etc. to reduce the adsorption or accumulation of dust.

- Used in the manufacture of housings and packaging materials for medical devices and instruments to prevent the influence of static electricity on the accuracy of precision medical instruments and prevent contamination of drugs.

Advantages of antistatic compound

- Long-lasting and stable antistatic performance: Compared with ordinary antistatic materials, antistatic compounds can maintain good antistatic performance for a longer time. This is because it uses a special polymer structure and long-lasting antistatic additives, which makes the antistatic effect long-lasting and not easy to decay over time. Whether in a dry environment or in the case of frequent friction, it can effectively prevent the generation and accumulation of static electricity, providing reliable static protection for the product.

- Good compatibility with matrix materials: The antistatic compound can be well-compatible with various polymer matrix materials and will not have adverse effects on the physical properties and processing properties of the material. During the processing, it can be evenly dispersed in the matrix material to form a stable structure to ensure the consistency of antistatic performance.

- Safe and reliable performance: Due to its long-lasting antistatic performance, it can effectively reduce the safety risks such as fire and explosion caused by static electricity, especially in some flammable and explosive environments, such as petrochemicals, electronic manufacturing, and other fields, and has important application value.

- Wide range of applications: Antistatic compounds can be used in a variety of fields, including electronics, automobile manufacturing, aerospace, medical and health care, etc. According to different application requirements, composite materials with different properties can be customized to meet the antistatic requirements in various complex environments.

- Environmental protection and energy saving: Some polymer antistatic composite materials use environmentally friendly raw materials and production processes, do not contain harmful substances, and meet environmental protection requirements.