PEEK Antistatic Plastic Properties

PEEK Antistatic Plastic Properties

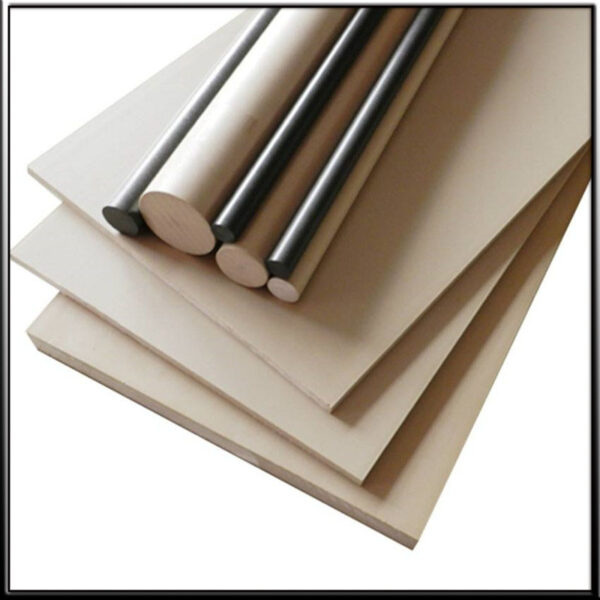

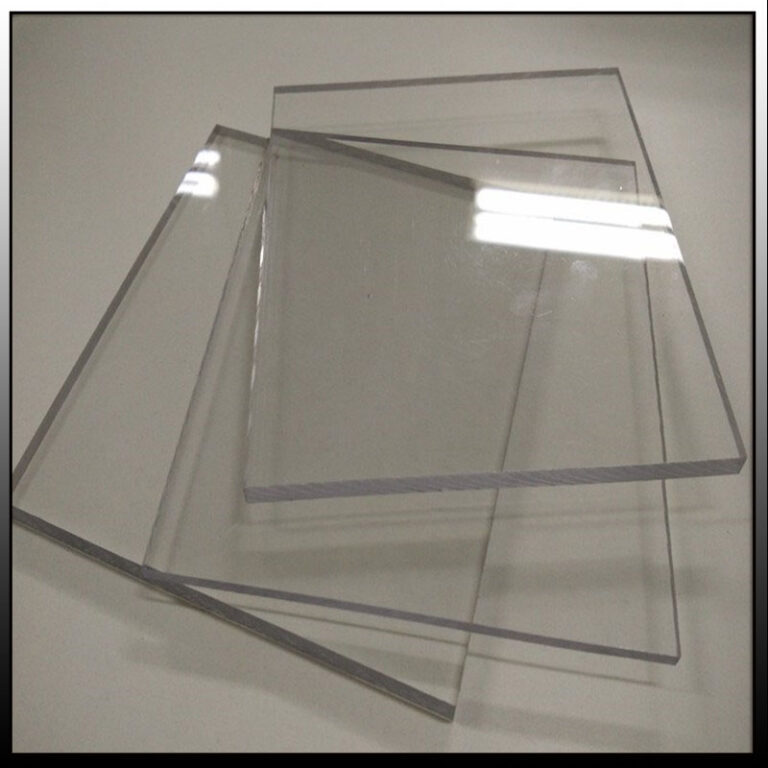

PEEK antistatic plastic sheet is is a unique semicrystalline, high temperature engineering thermoplastic.With high melting point (343°C) and excellent mechanical properties.Outstanding mechanical properties even at high temperatures,excellent dimensional stability.

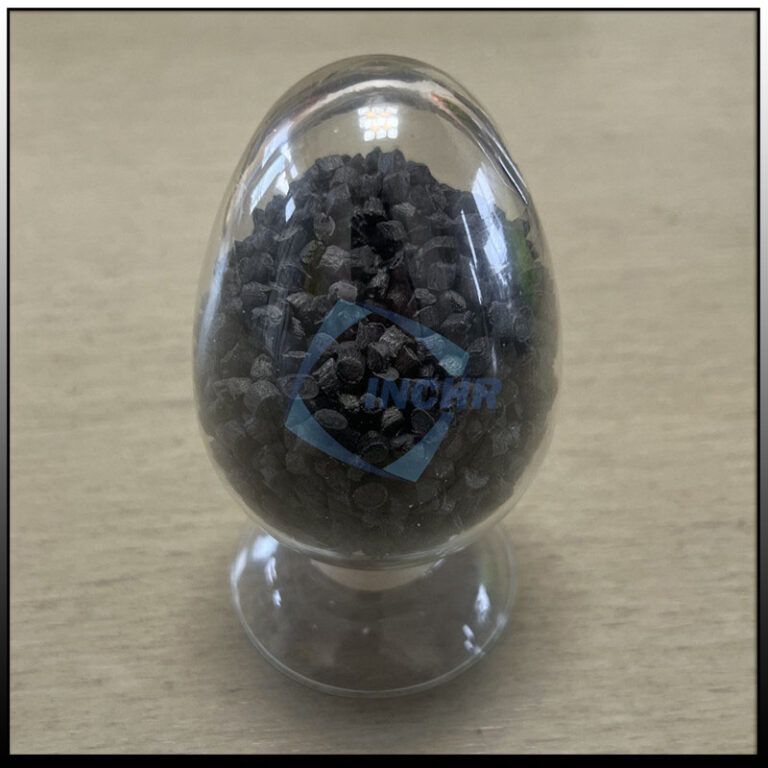

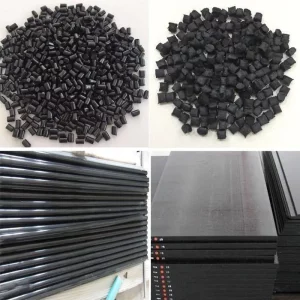

ESD PEEK compound is based on PEEK raw materials and is mixed with carbon black, metal fibers, and antistatic masterbatch. It can achieve anti-static, static dissipation, conductivity, and electromagnetic interference (EMI) functions.

ESD PEEK compound is a regular black solid object with a uniform and shiny color, hard texture, smooth surface, and density of 1.4-1.45g. ESD PEEK sheet has good antistatic properties, mechanical strength, rigidity, high hardness, high-temperature resistance, chemical resistance and hydrolysis resistance, wear resistance, and friction properties, high creep resistance, good dimensional stability, and UV resistance. It has the characteristics of high-energy radiation resistance, inherent low flammability, and low smoke production when burning.

Application Of PEEK Antistatic Plastic

Application Of PEEK Antistatic Plastic

PEEK antistatic plastic sheet is one of the highest performance thermoplastic plastics. which is used for semiconductor transportation and some of the most demanding applications, such as seals, gears, linings, bearings, pumps, and compressor assemblies, while providing the ability to make components with excellent performance at high temperatures, as the glass transition temperature is 186°C, for aerospace and automotive industries.

CA20 Series are ESD PEEK compunds which widely used in automobile and aviation fields,automobile fuel pump and gearbox. It can help equipment reduce weight, reduce noise and increase the service life of wear-resistant parts, reduce or even avoid the use of lubricants.

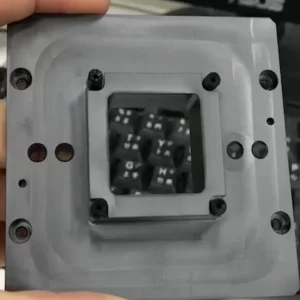

In the field of electronic equipment manufacturing, it is used to make packaging materials for electronic components. Because it can prevent static electricity from damaging precision electronic components and ensure the safety of components during transportation and storage. For example, after the chip is packaged, it is packaged with ESD PEEK material to prevent the chip from being damaged by static electricity breakdown.

In the field of aerospace, it can be used to manufacture the shells of some static-sensitive instruments and equipment in aircraft. The flight environment of the aircraft is complex, and the instruments are easily disturbed by static electricity. The ESD PEEK material shell can effectively protect against static electricity and ensure the normal operation of the instrument.