Introduction Of HIPS Antistatic Masterbatch

- HIPS antistatic masterbatch is a specially modified thermoplastic permanent antistatic additive. The surface resistance of the masterbatch is 10E7 Ohms, and after dosing, the extruded sheet is 10E8-10E9 Ohms . It has the advantages of long-term antistatic, no surface migration, no precipitation, and no falling powder. The addition amount is 50%-75%, and it can also be used directly to achieve a lower surface resistance.

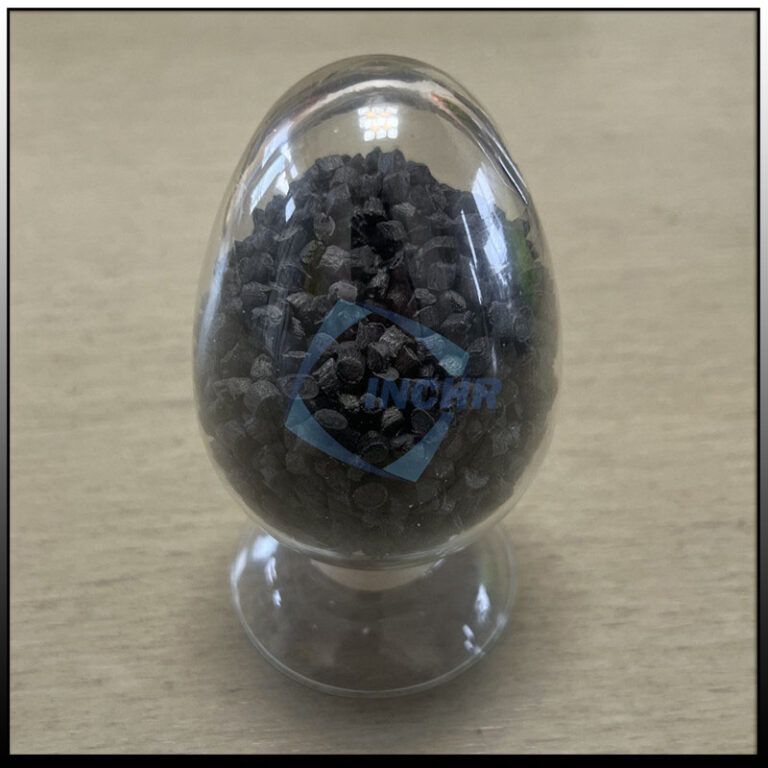

- The base material of HIPS antistatic masterbatch is high-impact polystyrene, which is modified by introducing rubber components into general-purpose polystyrene. It is a two-phase system composed of a rubber phase and a continuous polystyrene phase, and the appearance is usually opaque or milky white particles. Antistatic HIPS has a certain resistance to weak acids and weak bases but is more sensitive to strong acids, strong bases, and aromatic hydrocarbon organic solvents.

- By adding permanent antistatic agents such as polyether ester block polyamide resins and polyethylene oxide, a conductive network is formed inside the material, allowing static charges to be conducted inside the material to avoid static electricity accumulation. HIPS antistatic masterbatch has good fluidity and thermal stability. During the extrusion process, it can smoothly pass through the screw, die and mold of the extruder to form products of various shapes, such as sheets, pipes, profiles, etc.

- HIPS antistatic masterbatch retains the high impact strength and toughness of HIPS itself. The products made can withstand certain external force impacts during use without being easily broken. After extrusion molding, the product has high dimensional accuracy, small shrinkage, and can maintain a stable shape and size, meeting the strict requirements of product size in different application fields.

Main Application Areas Of HIPS Antistatic Masterbatch

Electronic field

- Electronic component tray: used for IC tray, LCD tray, electronic parts tray and FPC tray, etc., which can effectively prevent static electricity from damaging electronic components and ensure the stability of components during transportation and storage.

- Electronic product packaging: can be made into outer packaging boxes and inner trays of electronic products to avoid interference or damage to electronic products caused by static electricity accumulation, such as packaging of electronic products such as mobile phones and computers.

- Electronic device shell: Some electronic device shells that are sensitive to static electricity will use HIPS antistatic masterbatch, which can not only provide certain mechanical protection, but also prevent static electricity from affecting the normal operation of the internal circuit of the equipment.

Packaging field

- Food packaging: can be used to make food trays, inner trays, etc., with good hygienic properties, can directly contact with food without producing harmful substances, and the antistatic properties can reduce dust absorption and keep food packaging clean.

- Daily necessities packaging: such as the packaging of daily necessities such as cosmetics and stationery, HIPS antistatic masterbatch can make the packaging less likely to absorb dust and debris during transportation and display, keep the appearance clean, and enhance the product image.

Other fields

- Medical equipment parts: In some medical equipment, some parts that are sensitive to static electricity use HIPS antistatic masterbatch to prevent static electricity from interfering with the electronic components or sensors of the equipment, ensuring the accuracy and stability of the medical equipment.

- Automotive interior parts: It can be used for some parts of automotive interiors, such as instrument panels, door interior panels, etc. The antistatic property helps to reduce dust absorption and keep the interior clean. At the same time, its good impact resistance can also meet the use requirements of automotive interiors.