Introduction To Antistatic Polycarbonate

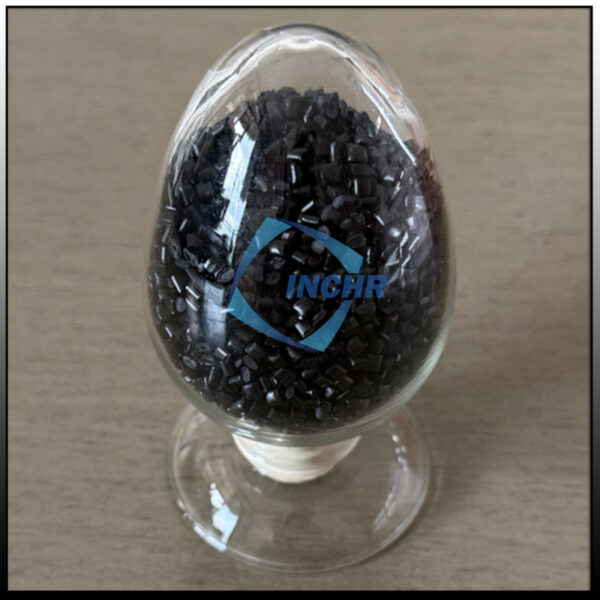

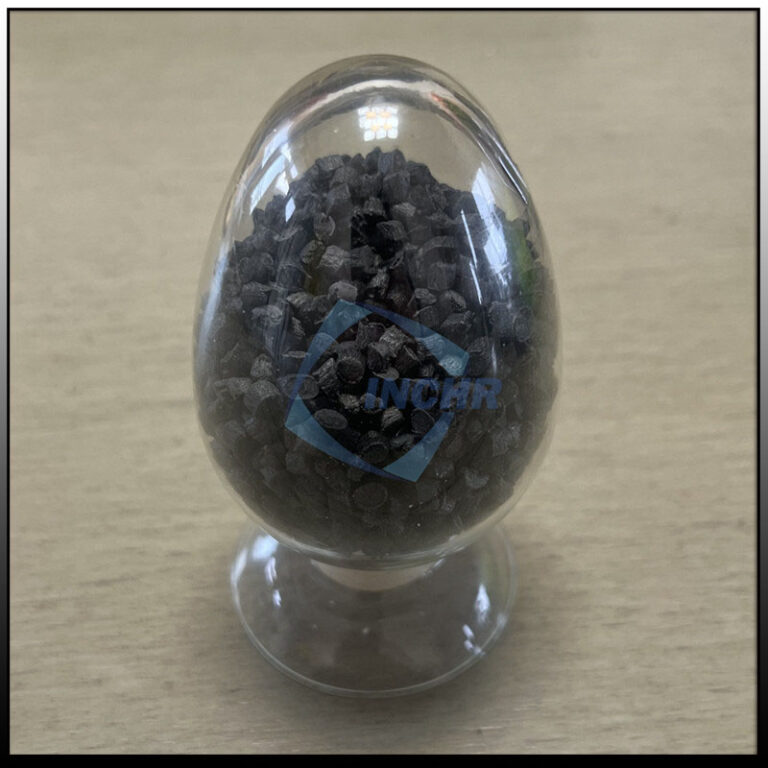

- Antistatic polycarbonate compound is a new type of material with antistatic properties, which is based on polycarbonate (PC) and carbon nanotube as key functional additives, and is compounded through a specific process. It is usually in black granular form.

- Excellent antistatic performance: Carbon nanotubes have unique electrical properties. After being evenly dispersed in the polycarbonate matrix, they can form a conductive network, which significantly reduces the surface resistivity of the composite material, quickly removes static charges, and effectively prevents the harm caused by static electricity accumulation, such as static electricity adsorbing dust and causing electronic components to break down.

- Good mechanical properties: It inherits the high strength and toughness of the polycarbonate material itself, has excellent impact resistance, is not easy to break, and can meet application scenarios with high requirements for structural strength. Even under complex stress conditions, such as tensile, bending, compression, and other external forces, it can still maintain a stable physical form.

- Excellent thermal stability: The heat resistance of polycarbonate materials is good, and it is further improved after adding carbon nanotubes. It can be used normally in a wide temperature range and is not easily softened and deformed by high temperatures. It is suitable for some environments that need to withstand a certain amount of heat, such as peripheral components of the heat dissipation area of electronic equipment.

Advantages Of Antistatic Polycarbonate

- Balanced performance: The antistatic, mechanical, and thermal properties are cleverly integrated. Compared with materials with single properties, it can meet complex design requirements in one stop and reduce the tediousness and compatibility issues of using multiple materials.

- Lightweight: Carbon nanotubes have a very high strength-to-weight ratio. While improving the performance of the material, it will not significantly increase the overall weight of the material, which is conducive to the lightweight design of the product. It is of great significance for weight-sensitive industries such as aerospace and automobiles.

- Long-term effect: The antistatic performance of antistatic polycarbonate is permanent. Unlike some short-term antistatic agents that will fail over time or increase in the number of uses, it can play a stable role throughout the life cycle of the product.

Applications Of Antistatic Polycarbonate

- Electronic equipment shielding components: In 5G base stations, radars, and other equipment with strict requirements on the electromagnetic environment, antistatic polycarbonate compounds can be used to make shielding covers, shielding shells, and other components to effectively block internal electromagnetic signal leakage and external electromagnetic interference, and ensure the normal operation of the equipment and the stability of signal transmission.

- Electromagnetic compatibility test environment: In the electromagnetic compatibility laboratory, the use of antistatic polycarbonate compounds to make test fixtures, test platforms, etc. can provide a stable electromagnetic shielding environment for testing, reduce the impact of external electromagnetic noise on test results, and improve the accuracy and reliability of the test.

- Electronic and electrical field: Widely used in the shells of electronic products such as computers and mobile phones, it not only protects the internal circuits from electrostatic interference but also meets the requirements of strength and transparency of the appearance design; it is also used for antistatic trays and turnover boxes of electronic components to ensure that the components are not damaged by static electricity during storage and transportation.

- Automobile manufacturing: Antistatic polycarbonate compounds in automobile interior parts such as dashboards and center consoles can prevent static electricity generated by passengers getting on and off the car, improving driving comfort; at the same time, in the protective shell of the automotive electronic control system, it ensures stable signal transmission and avoids malfunctions caused by static electricity.