Introduction Of Permanent Antistatic Additive For PP

Introduction Of Permanent Antistatic Additive For PP

● Permanent antistatic additive for PP is an antistatic additive for polypropylene (PP) materials. It has good compatibility with PP resins and can be evenly dispersed in the material without affecting the physical properties and processing properties of the material.

● 600AN is designed for extrusion processing. Suitable for single-layer or three-layer ESD PP and PS sheets for thermoforming trays. The recommended dosage level is 8-20%wt.

● PP20AN is one of the permanent antistatic additives for PP resin. It has excellent antistatic properties in homopolymer PP and copolymer PP. It is suitable for the application of ESD PP injection molding and PP pipes. PP20AN is ideal for BOPP film applications in the electronic packaging industry, with a surface resistivity of < 10^9; the heat seal strength is maintained at 130C, 0.5s.

● Permanent antistatic additive for PP is compatible with both PP and PS resins. It is recommended to compound with the matrix before processing (injection, extrusion, blow molding). The antistatic materials after compounding can maintain the initial mechanical properties of the polymer, even with a dosage of up to 25%. 3%-5% of compatibilizer is recommended to use.

Advantages Of Permanent Antistatic Additive For PP

● Good physical properties: When adding 8-20wt% of permanent antistatic additive, it has antistatic properties, high strength, high stiffness, high heat resistance, and chemical resistance. It also has good chemical corrosion resistance and has a certain resistance to acids, alkalis, organic solvents, etc.

● Good processing performance: Similar to ordinary PP resin, it can be processed by common processing methods such as injection molding, extrusion, blow molding, etc., and it is easy to form products of various complex shapes. For example, trays for food packaging.

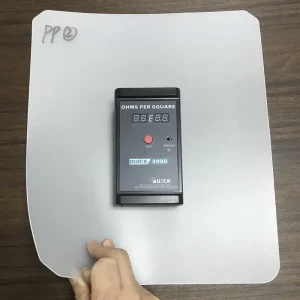

●Long-term and stable antistatic performance: Immediately after processing (injection molding, extrusion, blow molding), it shows long-lasting antistatic performance, which is long-lasting and stable and will not fail quickly over time. The antistatic performance is both washable and friction-resistant.

● Transparent color: The permanent antistatic additive for PP is light yellow or translucent, so it is suitable for any colorful ESD PP, transparent and translucent formulas can be customized.

● Safety and environmental protection: It does not contain harmful substances and is used in some fields with high safety requirements, such as food packaging, medical equipment, etc.

Why Choose INCHR@ Permanent Antistatic Additive For PP

- In terms of research and development, the team is composed of elites, and its members come from professional fields such as materials and chemicals, with both profound academic and practical skills. They deeply explore the trend of polypropylene and antistatic technology, continuously experiment and innovate, optimize products such as 600AN and PP20AN, and keep the products at the forefront of the industry.

- The production is equipped with internationally advanced equipment, the fully automated system strictly controls the proportion of raw materials, and the high-precision mixing device makes the antistatic additive and resin blend perfectly, ensuring stable quality without fluctuations, and outputting reliable materials for customers.

- The quality inspection system is strict, INCHR conducts simulation tests on permanent antistatic additives and tests their performance in extreme environments such as high temperature, high humidity, strong acids, and strong alkalis. Only products that meet the standards can enter the market to ensure high quality.

- The customized service is outstanding, and the process and formula can be quickly adjusted according to the needs of multiple fields such as electronics, food, and medicine. For example, PP20AN with low resistivity and stable heat sealing strength is customized for electronic packaging.