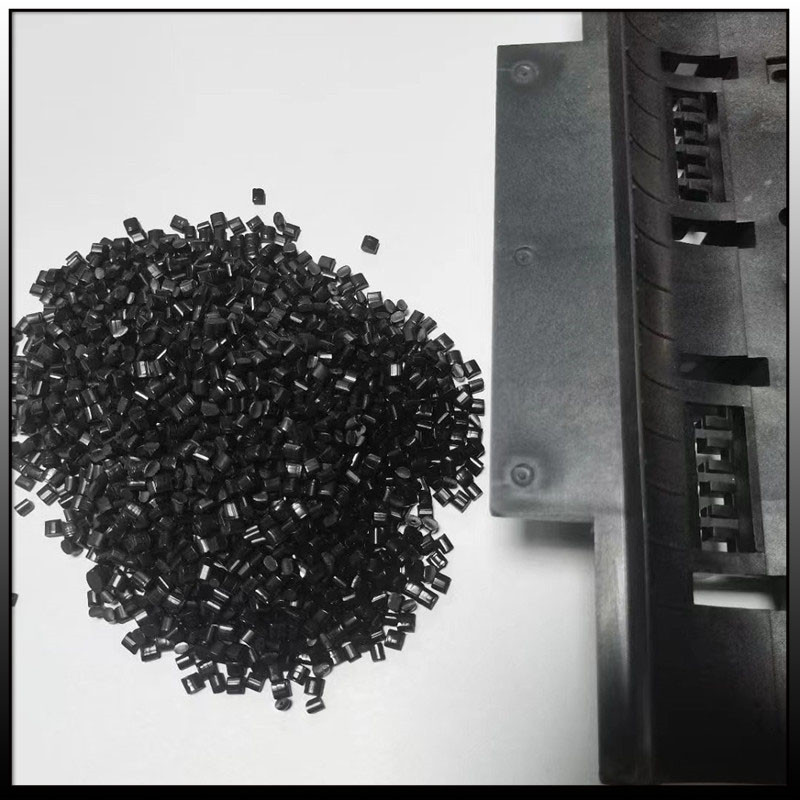

Carbon Fiber Filled Compounds

INCHR@ Injection grade carbon fiber reinforced composites are based on?

Carbon fiber reinforced nylon (PA)

Such as PA6 and PA66, with high strength, high rigidity, good wear resistance, and chemical corrosion resistance. INCHR@ injection-molding grade carbon fiber reinforced composites contain 10%-30% carbon fiber and 5% PTFE lubricant, which are used for connectors, reels, etc. of electronic appliances, as well as cooling fans, door handles, and other parts of automobiles. The nylon-based series has the characteristics of thermoplasticity, lightweight, and good toughness.

Carbon fiber reinforced polypropylene (PP)

It has the advantages of low density, good water resistance, and high chemical stability, and has good processing performance. It can be molded into products with complex shapes by injection molding. It is often used in the fields of automotive interiors, electrical housings, etc., and can achieve lightweight while ensuring performance.

Carbon fiber reinforced polycarbonate (PC)

After adding carbon fiber, its strength and rigidity are significantly improved. This material is often used in high-end electronic equipment housings, optical instrument components, etc., which can not only protect internal precision components but also meet the product’s requirements for appearance and performance.

Carbon fiber reinforced acrylonitrile-butadiene-styrene terpolymer (ABS)

Made of short carbon fibers mixed into the thermoplastic resin, it has a maximum tensile strength of 383MPa, which is more than 70% higher than general glass fiber reinforced resin and more than 15% higher than general carbon fiber reinforced resin. The anisotropy is small, the molded product is not easy to warp or twist, and the strength loss at the weld line is relatively small.

Carbon fiber reinforced polyphenylene sulfide (PPS)

Known for its high-temperature resistance and chemical corrosion resistance. After adding carbon fiber, its mechanical strength and rigidity are further improved, and its dimensional stability is better. It is often used for parts in high-temperature and high-demand environments such as aerospace, automotive engine peripheral parts, and electronic and electrical.

Carbon fiber reinforced polyetheretherketone (PEEK)

PEEK is a high-performance engineering plastic with extremely high heat resistance, wear resistance, radiation resistance, and good biocompatibility. PEEK carbon fiber reinforced composite not only maintains these excellent properties but also has higher strength and modulus. They have important applications in aerospace, medical equipment, high-end machinery manufacturing, and other fields, such as aircraft structural parts, artificial joints, etc.

Carbon fiber reinforced polyoxymethylene (POM)

POM has good mechanical properties, wear resistance, self-lubrication, and fatigue resistance. After carbon fiber reinforcement, its strength and rigidity are greatly improved, and the friction coefficient is further reduced. It is often used for precision machinery parts, automotive parts, gears, bearings, etc., which can improve the service life and work efficiency of parts.

Advantages over traditional plastics

Significant improvement in mechanical properties: It can significantly improve the tensile strength, bending strength, rigidity, and other mechanical properties of plastics, and can withstand greater loads and stresses. For example, in terms of tensile strength, carbon fiber reinforced plastic injection molding can often be several times or more improved than unmodified traditional plastics. Bending strength and stiffness will also be significantly improved. In addition, factors such as the content, length, distribution of carbon fiber, and the way it is combined with the plastic matrix will have an important impact on the performance of the carbon fiber reinforced polycarbonate.

Outstanding lightweight effect: Carbon fiber has the characteristics of low density. Use it to enhance and modify plastics. On the premise of ensuring that the mechanical properties of the material meet the requirements, the amount of material can be reduced, thereby reducing the overall weight. Compared with traditional metal materials, carbon fiber reinforced plastic injection molding is lighter in weight, helping to reduce energy consumption and improve operating efficiency. For example, 30% is the most common amount of carbon fiber used, and 30% carbon fiber reinforced nylon helps to achieve the light-weighting of traditional plastics.

Improved heat resistance: Carbon fiber reinforced plastic injection molding can improve the heat resistance of traditional plastics and maintain stable performance at higher temperatures. Traditional plastics have limited heat resistance, while carbon fiber has higher thermal stability. When carbon fiber is compounded with plastic, it can increase the thermal deformation temperature and long-term use temperature of the plastic to a certain extent. The addition of carbon fiber can hinder the movement of plastic molecular chains and reduce the thermal expansion coefficient, thereby enhancing the dimensional stability and performance retention capabilities of plastics in high-temperature environments.

Main application areas

Aerospace: Due to its high strength, lightweight, and high-temperature resistance, carbon fiber reinforced plastic injection molding can be used to manufacture aircraft components, such as wings, fuselage structural parts, etc., as well as parts of spacecraft, which helps to reduce the weight of aircraft and improve flight performance and reliability.

Automotive industry: It can be used to manufacture car body components, such as body panels, bumpers, etc., which can improve the strength and safety of the car while reducing the weight of the car body and reducing fuel consumption; it can also be used to manufacture car interior parts and engine parts, such as dashboards, seat frames, engine hoods, etc.

Electronic products: Suitable for manufacturing housings, structural parts, and other components of electronic products, such as mobile phone housings, laptop housings, tablet housings, etc. Carbon fiber reinforced plastic injection molding can provide good mechanical strength and electrical insulation performance, and can meet the requirements of electronic products for appearance design and thinness.

Sports equipment: Widely used in the field of sports equipment, such as bicycle frames, golf clubs, skateboard bodies, etc., carbon fiber reinforced plastic injection molding can improve the strength and rigidity of sports equipment, while reducing weight, and improving the performance and use experience of sports equipment.