Introduction Of Conductive Masterbatch

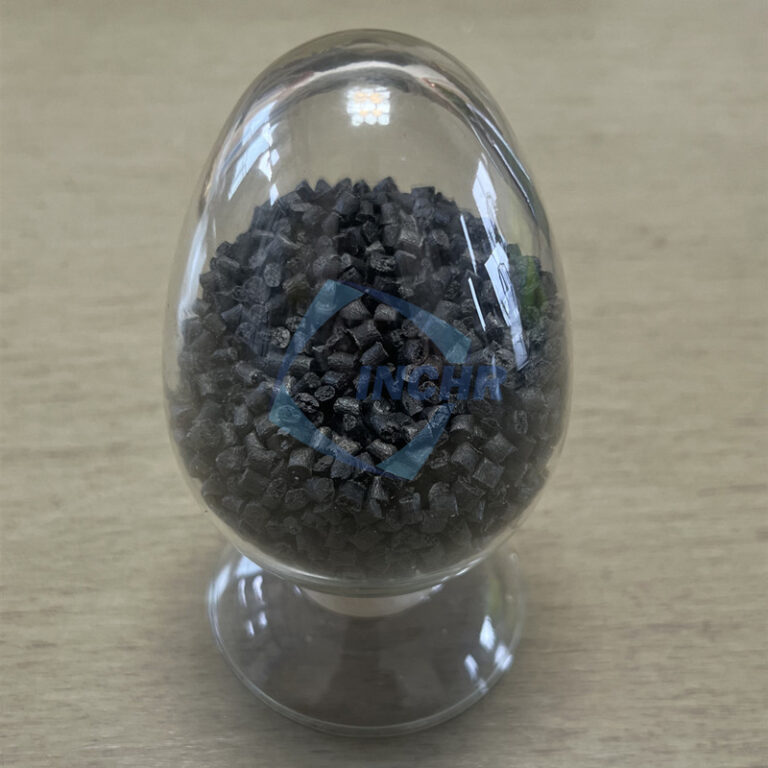

• Conductive masterbatch is a functional masterbatch made of pure resin as the matrix and conductive fillers with high oil absorption value and ultra-fine particle size as the conductive medium. It is granulated by adding toughening agents, reinforcing agents, coupling agents, antioxidants, and other additives through specific processes (such as internal mixers, twin-screw extrusion, etc.).

• Common types of base resins include PP, PS, HIPS, LDPE, HDPE, PVC, ABS, POM, Nylon, etc. Different base resin models are suitable for different processing technologies. For injection molding, extrusion, and blown film processes, there will be matching conductive masterbatch models, which have different melt indexes.

• The fillers in conductive masterbatch are formulated with carbon black, carbon nanotubes, and stainless steel fibers. The proportion of fillers determines the resistance of the masterbatch and also determines the amount of the masterbatch added to the terminal product. According to different applications, suitable fillers can be selected as masterbatches. The costs of various fillers are also different and carbon black conductive is most cost-effective.

Advantages Of Conductive Masterbatch

• Improving electrical conductivity: Significantly improve the electrical conductivity of plastic products, making them have functions such as anti-static or electromagnetic shielding.

• Uniform dispersion: The conductive masterbatch is effectively dispersed in the matrix to ensure the uniformity of conductive properties.

• Good stability: Can be evenly dispersed in the resin to form a stable conductive network, and maintain stable, long-lasting performance during processing and use.

• Reducing costs: Compared with pure conductive materials, conductive masterbatch can reduce costs by dosage.

• Excellent processing performance: It has little impact on the processing performance of plastics and is easy to process and shape.

• Good compatibility: The masterbatch is based on a variety of matrices, so it has good compatibility with various matrices.

• Design flexibility: The adjustable addition ratio provides more possibilities for product design. The formula and performance of the masterbatch can be adjusted according to different application needs and product requirements to meet diverse market demands.

Processing Instructions Of Conductive Masterbatch

Processing Instructions Of Conductive Masterbatch

1. Pre-drying: The conductive masterbatches is highly recommended to be dried before processing, especially carbon black conductive is a hygroscopic material.

2. Mixing: Select a masterbatch that is compatible with the base resin, and evenly mix it with the based resin in a certain proportion.

3. Processing: The mixed materials are processed into products through injection molding, extrusion, and other processes.

4. Control the dosage: According to specific needs, adjust the amount of conductive masterbatch to achieve the ideal conductive effect.

5. Testing: Add in strict accordance with the recommended proportion. Too much or too little may affect the conductive performance. They are conducting conductive performance testing on the finished products to ensure that they meet the requirements.

6. Different conductive masterbatches have different processing parameters to ensure product quality.

7. During storage, moisture, high temperature, and other adverse environments should be avoided to prevent the performance of the masterbatch from deteriorating.