Introduction Of PE Conductive Compound

Introduction Of PE Conductive Compound

- PE conductive compound is a polyethylene plastic raw material with conductive function and anti-static effect. It has appropriate conductive properties and anti-static properties by formulating appropriate PE resin.PE conductive compoundis usually black and is mainly used to produce conductive PE films.

- CT-08A is a conductive compound with conductive properties made of polyethylene (PE) as a carrier and conductive fillers (such as carbon black, carbon nanotubes, etc.). Due to its extremely low resistance, it can also be used as a conductive masterbatch. When the addition amount is 30-60%, it is designed for conductive films (thickness 0.015mm) to reach 1.0E+04~1.0E+06 ohms. The conductive masterbatch has stable conductivity and good dispersibility, and has little loss in the mechanical properties of the material. CT-08A is easy to use and can be processed after dry mixing to ensure that there is no powder falling on the surface of the final product.

- C403 is a carbon nano-based conductive compound with conductive properties formed by combining carbon nanotube with other substances. It has extremely high elasticity and toughness; its electrical conductivity is significantly better than graphene-based and carbon black-based conductive compounds, and the thinner the diameter and longer the length, the better the electrical conductivity; it has high thermal conductivity at room temperature and excellent axial thermal conductivity.

Application Cases Of PE Conductive Compound

- Used for semi-conductive shielding layers of wires and cables and shells and parts of electronic equipment. PE conductive compound can be used for semi-conductive shielding materials of medium and high voltage cables. This conductive compound is suitable for electronic equipment that requires electrostatic protection, such as shells and internal brackets, connectors, and other parts of mobile phones, computers, tablets, etc.

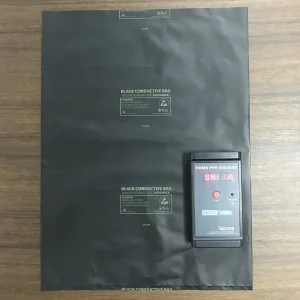

- Used to manufacture anti-static packaging for electronic components, such as anti-static trays, packaging bags, etc. It can avoid problems such as the adsorption of dust and damage to electronic components caused by static electricity during transportation and storage of electronic products, and provide a good electrostatic protection environment for electronic products.

- Used as packaging or turnover materials for automotive electrical, fuel systems, water tank radiators, dashboards, and other parts. The PE conductive compound can also be used for automotive interior parts, parts, etc., to reduce the interference of static electricity on automotive electronic systems, while improving the safety and comfort of the car, it can effectively prevent the generation and accumulation of static electricity.

- PE conductive film has a small friction coefficient and strong wear resistance, and can also be used in the energy field, mainly to protect precision parts from damage by static electricity. In special environments such as coal mines and oil tankers where flammable gas or dust exists, the use of conductive masterbatch to make equipment housings and parts, for example, ventilation ducts in coal mines and oil storage containers on oil tankers.

Classification Of INCHR@Conductive compound

- Carbon nanotube-based conductive compound: Carbon nanotubes, also known as buckytubes, are one-dimensional quantum materials formed by single or multiple layers of graphene curled around the central axis at a certain spiral angle. They have extremely high elasticity and toughness, with a Young’s modulus of nearly 6 times that of steel and a tensile strength of 100 times that of steel. Carbon nanotube-based conductive compounds are used as conductive agents for lithium-ion batteries, which can increase the capacity of the battery, reduce the amount of conductive agent, enhance electrolyte absorption, reduce the internal resistance of the battery, increase the high-rate discharge power density, and improve the cycle life; they can be used for nanoelectronic components such as diodes, triodes, nanowires, etc.; they can be used for wave absorption and shielding, heat conduction, enhancement, and conductivity in multifunctional polymer composite materials; they can also be used in hydrogen storage, energy storage materials, catalyst materials, sensors, atomic force microscope probes, supercapacitors, biosensors and other fields.

- Graphene-based conductive compound: Graphene is a honeycomb single-atom-layer planar film formed by carbon atoms in an sp2 hybrid manner. It is only 0.35nm thick and is one of the strongest materials. It also has good toughness, with a theoretical Young’s modulus of 1.0TPa and an intrinsic tensile strength of 130GPa. At room temperature, the carrier mobility is as high as 15,000cm²/(V·s), and it has excellent conductivity. Graphene-based conductive compounds can be used to prepare conductive films and transparent electrodes, such as touch screens and displays of electronic devices; adding graphene to composite materials can improve the electrical, thermal, and mechanical properties of the material, and can be used to manufacture high-performance aerospace materials, automotive parts, sports equipment, etc.; in the energy field, it can be used to prepare supercapacitors, battery electrode materials, etc.

- Carbon black-based conductive compound: Carbon black is a light, loose, and large-surface-area zero-dimensional carbon-based conductive nanoparticle that is inexpensive and easy to process. However, it is usually necessary to fill a large amount of carbon black conductive particles to transition from insulation to conductivity of the material, that is, its conductive percolation threshold is high. Carbon black-based conductive compounds are currently the most commonly used electrical conductive plastics in the preparation of ESD composite materials in industry. They are often used for conductive modification of polymer materials such as plastics and rubbers, such as antistatic plastics and conductive rubbers.

- Carbon fiber-based conductive compound: Carbon fiber has a high specific surface area and aspect ratio, which makes it easy to form a conductive network. At the same time, carbon fiber also has good mechanical strength and chemical stability. Carbon fiber-based conductive compounds can be used to prepare high-performance electrode materials, such as sodium ion batteries, supercapacitors, and other energy storage devices; as a reinforcement in composite materials, it improves the conductivity and mechanical properties of the material.