Introduction Of Antistatic Polymer For PS

Introduction Of Antistatic Polymer For PS

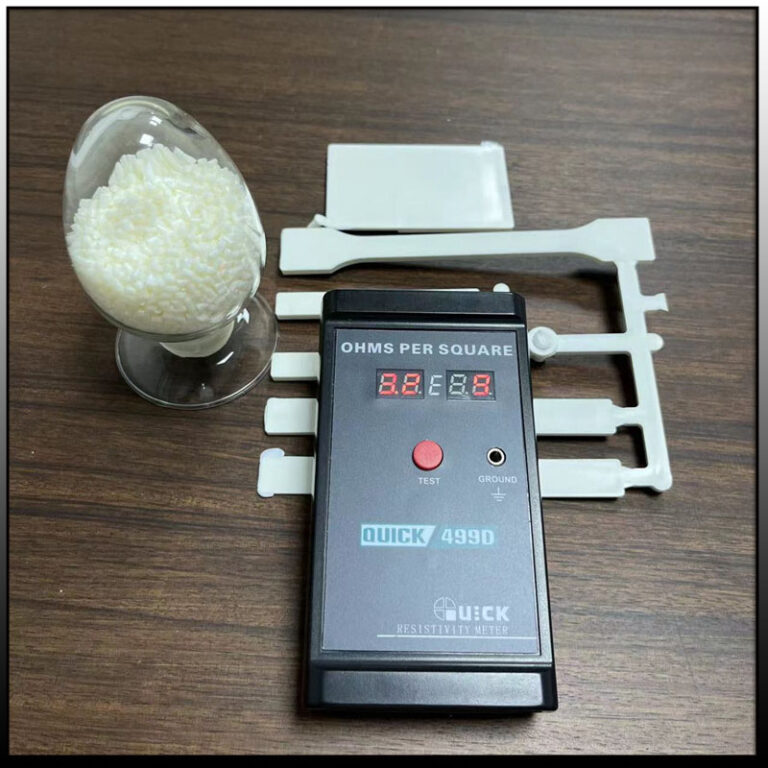

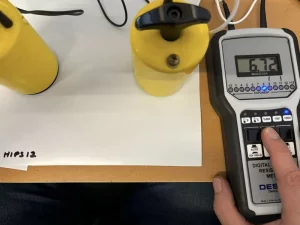

- Antistatic polymerfor PS is an antistatic agent specifically used for polystyrene resins. It is added to the resin during the production of polystyrene plastics so that it is evenly dispersed inside the plastic. The antistatic polymer has a lasting antistatic effect, but when added at 25%, it may have a certain impact on the physical properties of the plastic.

- Antistatic polymerfor PS can be processed on a conventional extrusion machine, typically at low shear conditions. Actual processing temperatures should be adapted according to the nature of the equipment and the manufactured article to give optimal quality.

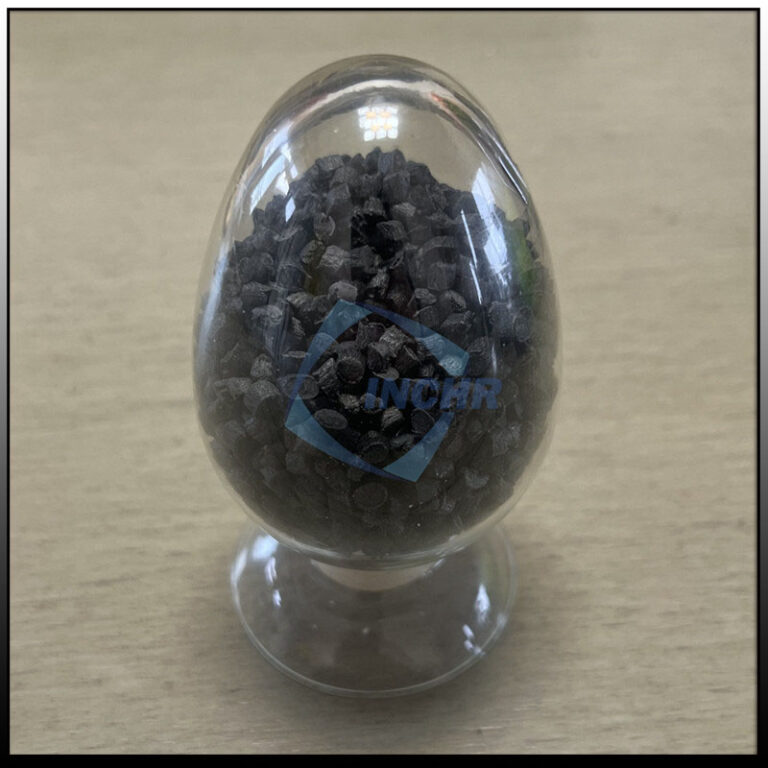

- 600K is anantistatic polymer designed for HIPS resin. It will not migrate on the end product or cause substrate atomization like antistatic chemical additives.

- 600C still maintains an antistatic effect in an extremely low humidity environment, unlike chemical additives that need to be in higher humidity to work; it takes effect immediately after adding to the polymer, unlike chemical additives that need a certain amount of time and humidity to have antistatic properties;

- 620K is an antistatic masterbatch based on the antistatic polymer for PS, used for PS extruded sheets and thermoforming films, it has thermal stability and good chemical resistance; it still has antistatic properties after recycling.

Classification Of Antistatic Polymer For Plastics

- Polyolefin antistatic polymer: This antistatic polymer has unique molecular configurations and structural properties. It is recommended for use in polyolefin resins such as polyethylene (PE) and polypropylene (PP) to produce antistatic packaging films, building materials, wires and cables, etc. Polyolefin antistatic polymer has good compatibility with polyolefins, it can effectively absorb the static charge in the surrounding environment and release it to achieve the effect of eliminating static electricity, has high thermal stability, and is not easy to cause plastic aging.

- Polyester antistatic polymer: Polyester antistatic polymer is an antistatic agent with polyester as soft segment and polyamide as hard segment. Its unique feature is that the antistatic agent is permanent and has no migration, which can effectively reduce static electricity accumulation. This antistatic polymer has strong adhesion to materials such as polyurethane, epoxy resin, and coating, and can play a good antistatic effect. The dosage is usually 8-20%, which can effectively reduce the surface resistance of the product to a surface resistance of 10E7Ω/sq-10E9Ω/sq. In addition, the antistatic polymer also has good water-washing resistance.

- Long-carbon polyamide antistatic polymer: The antistatic polymer is based on long-carbon polyetheramide elastomer (TPAE), and is produced by melt extrusion by adding different types of alkali metal sodium salts and lithium salts. Studies have shown that when the mass fraction of lithium perchlorate (LiClO4) is 6%, the antistatic agent is evenly distributed in TPAE, the antistatic effect is good, the surface resistivity can reach 10E7 Ω/sq, and the elongation at break is above 600%. Therefore, antistatic compounds containing long-carbon polyamides have outstanding mechanical properties and are suitable for applications with high mechanical requirements.