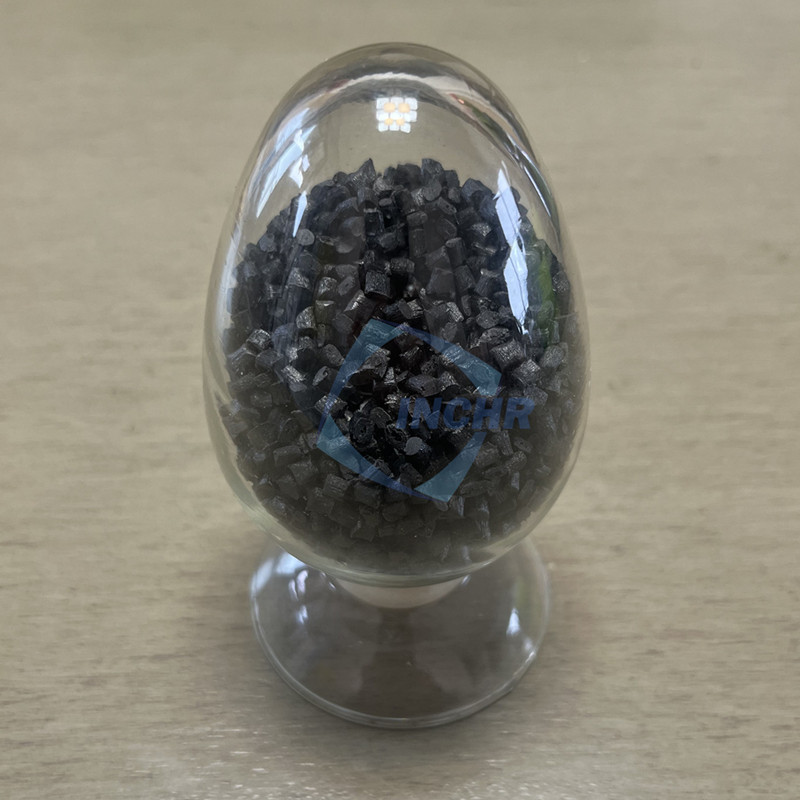

What is graphene reinforced conductive PVC?

Graphene-enhanced conductive PVC is a composite material obtained by adding graphene to polyvinyl chloride (PVC) material to significantly improve its conductive properties. Adding graphene to PVC is equivalent to adding a high-strength “skeleton” to the PVC matrix, which can effectively bear external forces and hinder the relative sliding of PVC molecular chains, thereby improving the mechanical properties of PVC.

Excellent conductive properties

Graphene-enhanced conductive PVC does have extremely superior conductive properties, which is mainly due to the unique structure and physical properties of graphene. Graphene is a two-dimensional material composed of a layer of carbon atoms arranged in a hexagonal honeycomb lattice. The chemical bonds between atoms are strong and electrons can move freely within them with extremely high mobility. When graphene is used as a reinforcing material and combined with other matrices, it can form an effective conductive path and significantly improve the conductive performance of the composite material. For example, in polymer-based composite materials, the addition of a small amount of graphene can significantly reduce resistance and enhance current conductivity. In addition, graphene’s large specific surface area and good interfacial compatibility also help to build a continuous and efficient conductive network in composite materials, further improving conductive efficiency.

Improve the problem of powder loss

This graphene-enhanced conductive PVC composite material solves the problem of “powder loss” of carbon conductive materials. It will effectively protect products and equipment from material contamination. Graphene-enhanced materials have a certain potential to improve the problem of powder loss. The problem of powder loss is usually related to the bonding force of the material, surface roughness, and the stability of the internal structure.

Graphene has excellent mechanical properties and a high specific surface area. When it is compounded with other materials, it can enhance the interfacial bonding force between materials and reduce the shedding of particles or powder. For example, the use of graphene enhancement in paint or coating can fill microscopic pores and defects, making the coating surface smoother and tighter, thereby reducing the possibility of powder loss. In addition, graphene can also improve the internal structure of the material, increase the integrity and stability of the material, and fundamentally reduce the occurrence of powder loss.

High thermal conductivity

Graphene has extremely high intrinsic thermal conductivity, with a theoretical value of up to 5300 W/(m·K). This characteristic makes it an ideal thermal conductivity enhancement material. When graphene is used to reinforce PVC, it can significantly improve its thermal conductivity. The reason is that the two-dimensional planar structure of graphene can provide efficient heat conduction paths and reduce thermal resistance. For example, adding graphene to a polymer matrix can create a continuous thermal network that allows heat to be transferred quickly. Compared with materials without graphene, the thermal conductivity can often be increased several times or even dozens of times. In addition, factors such as the amount of graphene added, the degree of dispersion, and the interface combination with the matrix material will have an impact on the thermal conductivity of conductive PVC.

About INCHR

INCHR has been committed to the research and development of graphene PVC soft graphene-reinforced plastic materials, improving the performance of PVC by combining with graphene. We offer a range of high-performance graphene-reinforced plastics such as conductive PVC and anti-static PVC. Graphene-enhanced conductive PVC is widely used in electromagnetic shielding, electrostatic shielding, electromagnetic radiation protection, and other applications. It is used to produce electronic equipment housings, shielding components of communication base stations, shielding covers of automotive electronic equipment, shielding layers of connecting wires, etc., to ensure the stable operation of automotive electronic systems in complex electromagnetic environments. It can also be used to make work surfaces, floor materials, etc., quickly dissipate static electricity generated by the human body and equipment, maintain environmental static balance, and protect the safety of experimental equipment and samples.This graphene-reinforced conductive PVC composite offers new electrical, thermal, and mechanical strengths, self-lubricating properties, and high flow properties.