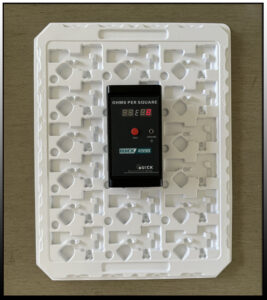

Polystyrene (PS) resin is a thermoplastic with good transparency, rigidity, and processing performance. High-impact polystyrene (HIPS) is a PS-modified plastic with better impact resistance. The natural antistatic HIPS compound for producing HIPS/PS trays is a polystyrene material with permanent antistatic ingredients added. This compound can be used to manufacture trays and play a role in electronic component packaging, food packaging, etc. It can effectively prevent static electricity from causing damage to products, such as adsorbing dust and causing electronic component breakdown.

Features of natural antistatic HIPS compounds for producing HIPS/PS trays

• Long-lasting antistatic performance

Unlike ordinary antistatic agents, natural antistatic HIPS compounds have a conductive network or a special molecular structure. During the entire service life of the material, static electricity can be stably conducted away, and the surface resistance will not increase significantly due to time and environmental changes (such as temperature and humidity fluctuations), and can be continuously maintained within the effective range of antistatic (generally 10^7-10^8Ω).

• Good physical properties

Strength and stiffness: The good strength and stiffness of polystyrene (PS) and high-impact polystyrene (HIPS) are maintained. This allows the pallet to withstand a certain weight of goods and will not easily deform during stacking or transportation, ensuring the structural integrity of the pallet.

Toughness: Especially when HIPS is used as the base material, its own impact toughness is retained. When encountering collisions or falls during transportation, the pallet can resist impact, reduce the risk of breakage, and protect the items carried.

• Excellent processing performance

It has good fluidity and can smoothly fill the mold cavity or form the required shape in tray processing processes such as injection molding and blister molding. Its processing temperature range is relatively wide. Under appropriate processing conditions, it can effectively avoid excessive waste generated during the processing process and improve production efficiency.

• High chemical stability

It can resist the erosion of a variety of chemical substances, such as some common acid and alkali solutions, organic solvents, etc. In actual use scenarios, it may be exposed to detergents, certain ingredients in food, or chemicals in industrial environments. This chemical stability can prevent the tray from being damaged by chemical corrosion and extend the service life of the tray.

• Good appearance quality

The natural antistatic HIPS compound has a high gloss. If HIPS raw materials with good transparency are used, after adding transparent permanent antistatic ingredients, a certain degree of transparency can still be maintained, and the tray will not become turbid due to the addition of antistatic ingredients. This is very important for some application scenarios (such as retail packaging) that need to display the contents of the tray.

Precautions for processing natural antistatic HIPS compounds

• Pre-drying treatment

Since HIPS raw materials have strong water absorption, they need to be dried before processing. Usually, the permanent antistatic PS compounds should be dried in a hot air circulation drying oven at 80-90℃ for 2-4 hours to reduce the moisture content of the raw materials to below 0.1%, so as to avoid moisture causing material performance degradation and surface defects (such as silver streaks, no bonding issue and bubbles) during processing.

• Temperature control

Barrel temperature: During processing, the barrel temperature is generally set between 180-260℃. Too low temperature will lead to incomplete plasticization of the raw materials, poor fluidity, and affect the molding quality of the tray; too high temperature may cause raw material decomposition, reduce material performance, and increase energy consumption.

Mold temperature: The mold temperature is usually maintained at 30-70℃. Appropriate mold temperature helps the molding of the tray and improves the surface quality and dimensional accuracy of the tray. If the mold temperature is too low, the tray may have short shots and poor surface gloss; if the mold temperature is too high, the molding cycle will be extended and production efficiency will be reduced.

• Screw speed

The screw speed should be moderate, generally between 30 and 60 rpm. Too fast a speed will cause excessive shearing of the natural antistatic HIPS compounds in the barrel, generating too much frictional heat, which may lead to decomposition of the raw materials and uneven mixing of the materials; too slow a speed will extend the processing cycle and affect production efficiency.

•Mixing uniformity

If multiple additives (toughening agents, compatibilizers, etc.) are added, ensure that these additives are fully mixed and uniform in the HIPS raw materials. You can use a high-speed mixer or a twin-screw extruder for pre-mixing to avoid inconsistent performance of the pallet due to uneven mixing, such as poor antistatic performance or insufficient toughness in some areas.