Classification Of ESD TPU Compound

ESD TPU compounds are based on thermoplastic polyurethane (TPU) and are compounds with antistatic properties formed by adding conductive masterbatches or permanent antistatic agents.

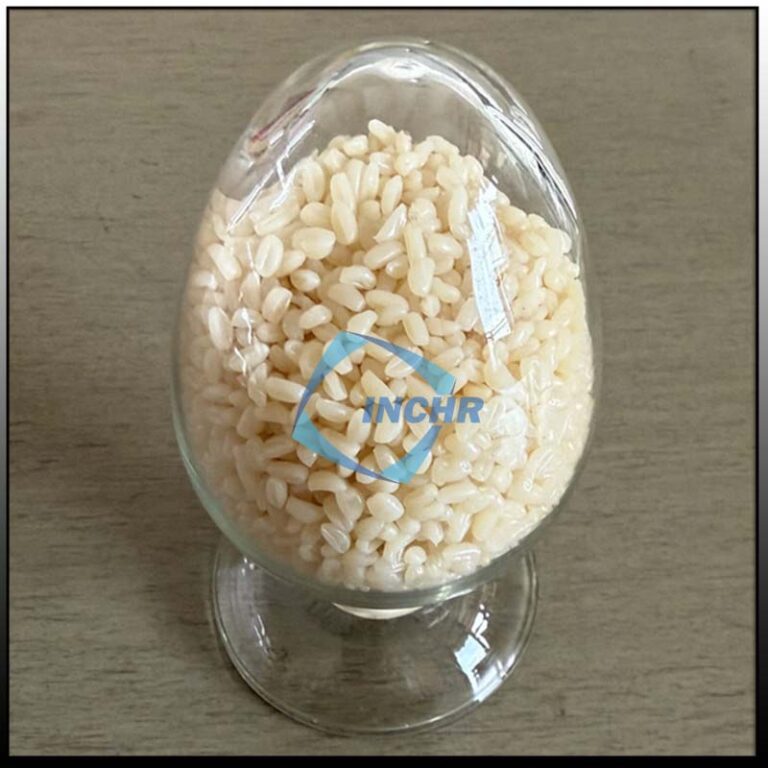

- Permanent antistatic agent grade ESD TPU compounds: By adding special permanent antistatic agents to TPU raw materials, a stable conductive network or ion channel is formed inside the TPU material to achieve the antistatic effect.

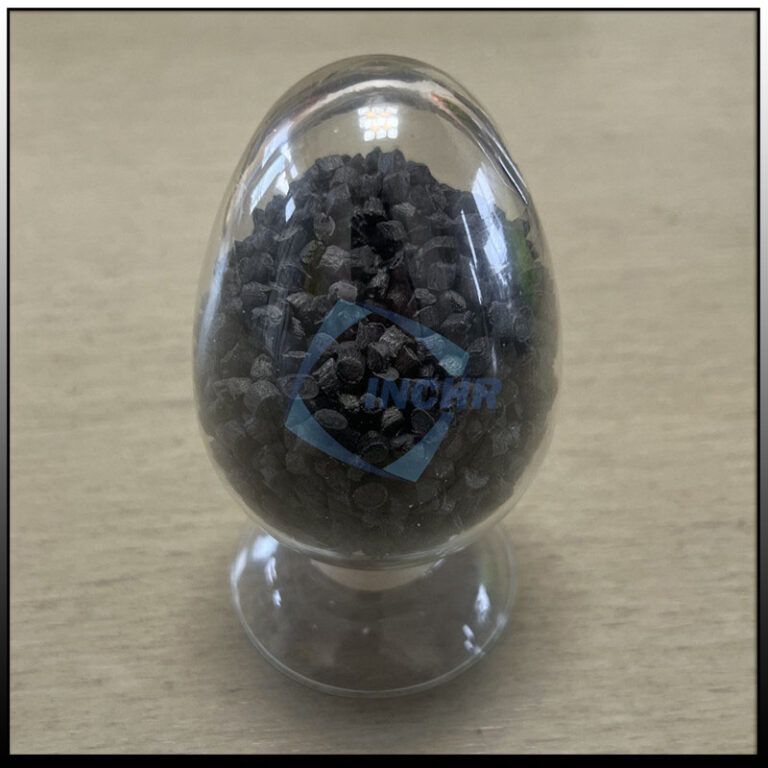

- Carbon nanotube grade ESD TPU compound: Taking advantage of the excellent conductive properties of carbon nanotubes, they are added to TPU materials to form a conductive network, allowing charges to be quickly transferred and dissipated.

- Conductive fiber-reinforced grade ESD TPU compound: Conductive fibers are compounded with TPU materials, and the conductive fibers form a continuous conductive path in the TPU matrix to conduct static electricity.

Performance Characteristics Of ESD TPU Compound

ESD TPU is a thermoplastic antistatic compound with excellent antistatic properties, good physical properties, and excellent processing performance. It is often used on special occasions to reduce safety risks such as fire and explosion caused by static electricity.

- Permanent antistatic: After special antistatic modification, ESD TPU has a relatively long-lasting antistatic effect, will not lose its antistatic ability due to short-term use or slight friction, can maintain stable antistatic performance for a long time, and is not easily affected by the external environment.

- Good flexibility: ESD TPU has good elasticity and softness, can adapt to the needs of different shapes and curves and performs well in some application scenarios that require bending, folding, or twisting. It also has good elasticity, which refers to the degree to which deformation stress is quickly released to its initial state, expressed in terms of recovery energy. Excellent low-temperature flexibility, most films can maintain flexibility even when exposed to as low as -20 degrees Celsius. Good temperature resistance, temperature resistance up to 130 degrees Celsius, polyether series temperature resistance up to 90 degrees Celsius.

- Excellent wear resistance: It has excellent wear resistance and can maintain a long service life under high friction conditions. It is suitable for application environments of friction and wear, such as soles, conveying pipelines, etc.

- High tensile strength and tear strength: It has high mechanical strength and can withstand certain tensile and tear stresses, ensuring that it is not easy to break or break during use, and providing reliable physical performance support for the product.

- Good weather resistance: ESD TPU can maintain stable performance under different environmental conditions, such as high temperature, low temperature, humidity, ultraviolet radiation, etc., and is not prone to aging, degradation, or performance changes, and is suitable for various complex use environments.

- Good oil resistance: Good resistance to grease, organic solvents, etc., and is not prone to swelling, deformation, or performance degradation when exposed to oily substances. It is suitable for some working environments that may be exposed to oil, such as automotive parts, mechanical seals, etc.

- Good thermoplasticity: ESD TPU has good thermoplasticity and can be formed by various processing methods such as thermoforming, injection molding, extrusion, calendering, etc. The processing process is relatively simple and easy to operate and can adapt to the manufacturing needs of products of different shapes and sizes.