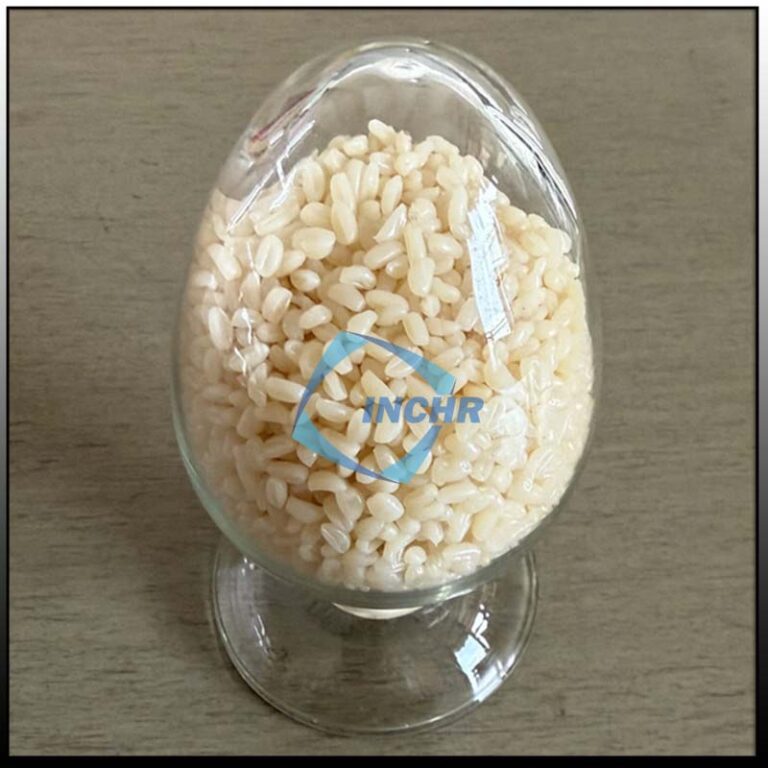

Introduction Of INCHR@Antistatic Masterbatch

Introduction Of INCHR@Antistatic Masterbatch

- INCHR@Antistatic Masterbatch is a functional masterbatch with natural antistatic properties, offering permanent antistatic effects (independent of humidity), excellent compatibility with resins, and minimal impact on product performance. It effectively addresses static electricity issues in materials such as LLDPE film, PP stretch film, ABS sheet, PA6 sheet, TPU film, and HIPS thermoforming sheet.

- INCHR offers various permanent antistatic masterbatch models compatible with LLDPE, HDPE, ABS, MABS, HIPS, PP, PA, and TPU resins. Composed of carriers, antistatic additives, and other additives, it boasts low addition amounts and optimal comprehensive cost.

- INCHR@P109AN: Suitable for single-layer or three-layer co-extruded PE-based films, with minimal impact on transparency.

- INCHR@120T: Ideal for injection molding and extrusion of transparent ABS substrates.

- INCHR@1505AN: Suitable for common ABS or PA6 resins, and applicable to injection molding and extrusion processes.

- INCHR@PS302AN: Applicable to HIPS thermoforming sheets, without affecting impact strength while ensuring excellent mechanical properties and antistatic performance.

- Usage: Dry-blend or compound with raw materials in the recommended proportion, then directly use for injection, extrusion, or blowing to ensure even dispersion. The specific dosage is adjustable based on product type, usage requirements, and processing technology. INCHR also provides customized solutions for special applications.

Features Of INCHR@Antistatic Masterbatch

- No exudation: After INCHR@ antistatic masterbatch is mixed with resin and processed into finished products, the antistatic components in it will not migrate from the interior of the product to the surface and form precipitates over time or due to environmental changes (such as temperature, humidity, friction, etc.). The core reason for this characteristic is that the antistatic components are stably present in the resin matrix through chemical bonding and will not be released to the surface of the product like some traditional small-molecule antistatic agents. No exudation ensures that the surface of the product remains clean and avoids phenomena such as stickiness and blooming.

- Long-lasting & stable effect: Unlike traditional antistatic agents, it has no induction period, remains effective after wiping or washing, and maintains stable antistatic properties for 5–10+ years.

- Humidity independence: Conductive properties are not affected by air humidity, ensuring consistent performance across conditions and overcoming the humidity sensitivity of small-molecule antistatic materials.

- Good compatibility: Customizable resin carriers ensure excellent compatibility with product resins, enabling even dispersion in plastic products.

- Minimal impact on performance: Little effect on processing, color, or mechanical properties of end-products.

Applications Of INCHR@Antistatic Masterbatch

Applications Of INCHR@Antistatic Masterbatch

Range Of End Products

The antistatic masterbatch is widely applicable to various plastic products and processing scenarios, including:

- Process methods: Injection molding, blow molding, blister molding, blown film, cast film.

- End-product types: Packaging films (electronic packaging film, stretch film, bubble bags, flat bags), plastic sheets, antistatic packaging materials, vacuum cleaner parts, household tools, and surface materials/flooring for special occasions (e.g., dust-free workshops, flammable/explosive environments).

Key Application Fields

- Electronics Industry: Used in electronic component packaging films and IC trays, it prevents static buildup and damage to sensitive electronic components. It can also be used in the production of antistatic flooring and work surfaces, creating an antistatic production environment.

- Medical Industry: Used in the manufacture of medical device housings, medical catheters, surgical instruments, and other applications, it prevents static electricity from attracting dust and microorganisms, potentially affecting medications or patients. Some transparent formulations also facilitate internal inspection.

- Packaging Industry: Suitable for food and pharmaceutical packaging, it prevents static electricity from attracting dust and impurities, ensuring the cleanliness and hygiene of the package contents. It can also be used in the packaging of precision instruments and optical lenses, preventing static electricity from attracting dust and affecting product quality.

- Automotive Industry: Used in automotive interior components, turnover packaging for accessories in automobile production workshops. It can also be used in automotive fuel lines and other components to prevent safety hazards caused by static electricity.

- Textile industry: Adding it to fibers can make antistatic fabrics, which can be used to make antistatic work clothes. They are suitable for electronic workshops, gas stations, and other places. They can also be used for daily clothing to reduce the embarrassment of static electricity.

Will INCHR@Antistatic Masterbatch Migrate?

The answer is absolutely no migration.

The antistatic masterbatch produced by INCHR is a polymer material with a long-lasting antistatic effect obtained by reactor polymerization. It can form a percolation network with conductive ability on the plastic surface to play an antistatic role. It is added to the base material by dry mixing and has the advantages of non-migration, durability, strong environmental adaptability, and water resistance.

- Intrinsic dissipative antistatic masterbatch: Taking LLDPE antistatic masterbatch as an example, this type of masterbatch can be added to the plastic during blending, extrusion, or injection molding. It works by using a continuous polymer phase. The ions in it act as charge carriers to dissipate the electrostatic field and will not migrate to the surface of the terminal product in the polymer.

- Carbon quantum dot composite antistatic masterbatch: Taking Nylon antistatic masterbatch as an example, carbon quantum dots are introduced into the antistatic nylon masterbatch obtained by a specific method. The carbon quantum dots are organically combined with the nylon molecular chain and evenly dispersed in the nylon. They have a similar matrix structure to the nylon resin and can form hydrogen bonds. While playing an antistatic role, they will not migrate.

- Thermoplastic polyester elastomer antistatic masterbatch: Taking TPU antistatic masterbatch as an example, as a long-lasting antistatic masterbatch of thermoplastic polyester elastomer TPEE carrier, it has good compatibility with thermoplastic elastomer and other resins. After dosing, it can achieve a permanent antistatic effect without migration and exudates.