Introduction Of Antistatic ABS Compound

- Antistatic ABS compound is a material obtained by adding a permanent antistatic agent and special additives to ABS resin for modification and processing. It can prevent the accumulation and discharge of static charge, thereby protecting electronic equipment from static interference or damage. It has the unique properties of permanent antistatic and colorability.

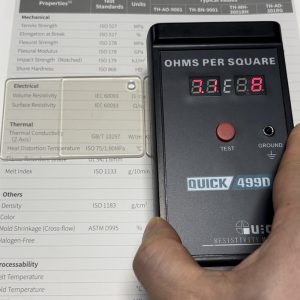

- The surface resistance of the antistatic ABS compound is usually between 10E8 and 10E10 ohms. The added antistatic agent is a polymer permanent antistatic agent. These antistatic agent molecules form the most closely oriented arrangement at the interface between resin and air or resin. After the resin is cured, the hydrophilic groups on the antistatic agent molecules are arranged toward the air side to form a monomolecular conductive layer to reduce the surface resistivity of the material and achieve the purpose of antistatic.

- Antistatic ABS compound focuses on improving the antistatic performance on the basis of maintaining the original mechanical properties of ABS resin; after adding the antistatic agent, it may have a certain impact on the mechanical properties of the material, such as strength, toughness, etc., which may change, but this impact can be minimized through reasonable formula design. 709AN and 747AN are suitable for conventional injection molding, extrusion, blow molding, and other processes; these two grades may need to be adjusted accordingly in the control of processing parameters such as temperature and pressure.

- 920AN is a transparent antistatic ABS compound based on Toray 920-555 resin, with a surface resistance of 10E8 Ohms. It not only has permanent antistatic performance, but also has the property of high transparency, and is used in electrostatic dissipation applications in the semiconductor and optical fields.

Characteristics Of Antistatic ABS Compound

Characteristics Of Antistatic ABS Compound

- Good impact strength: It can maintain high impact resistance even in low-temperature environments, which makes the terminal products of antistatic ABS not easy to break or damage when subjected to external force impact. For example, antistatic ABS plastic parts used in cold northern regions can still work normally under low-temperature conditions. It can be used to manufacture products that need to withstand certain impacts, such as helmets, sports equipment, etc.

- Excellent wear resistance: It has good wear resistance and can maintain good surface quality and dimensional stability during long-term use. It is suitable for manufacturing parts that are often subject to friction or wear, such as mechanical parts such as gears and bearings, and daily necessities such as mice and keyboards.

- High stiffness and strength: The material has strong rigidity and can withstand greater pressure and tension to ensure the shape and structural stability of the product. In the construction industry, antistatic ABS can be used to manufacture building models, decorative parts, etc., and can maintain the accuracy of their shape and size.

- Excellent processing performance: As the most widely used antistatic polymer, antistatic ABS has a wide processing temperature range, and good fluidity, and is easy to form through various processing processes such as injection molding, extrusion, and blow molding.It can quickly and efficiently produce terminal products of various shapes and sizes.

- Customizable functionality: By adding different additives or performing modification treatments, antistatic ABS compounds can be given different functions, such as fireproofing, glass fiber reinforcement, etc., to meet the needs of various special applications.

- Good surface gloss and easy coloring: The surface of antistatic ABS compound products has high gloss, a beautiful appearance, and is easy to color by dyeing or spraying. Products of various colors and appearances can be prepared to meet the needs of different consumers.