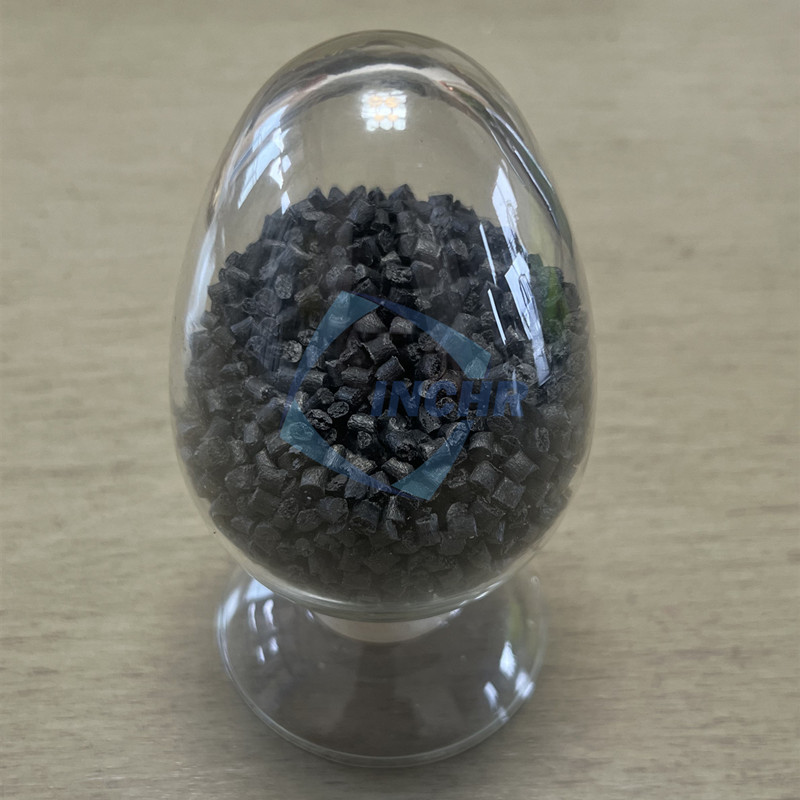

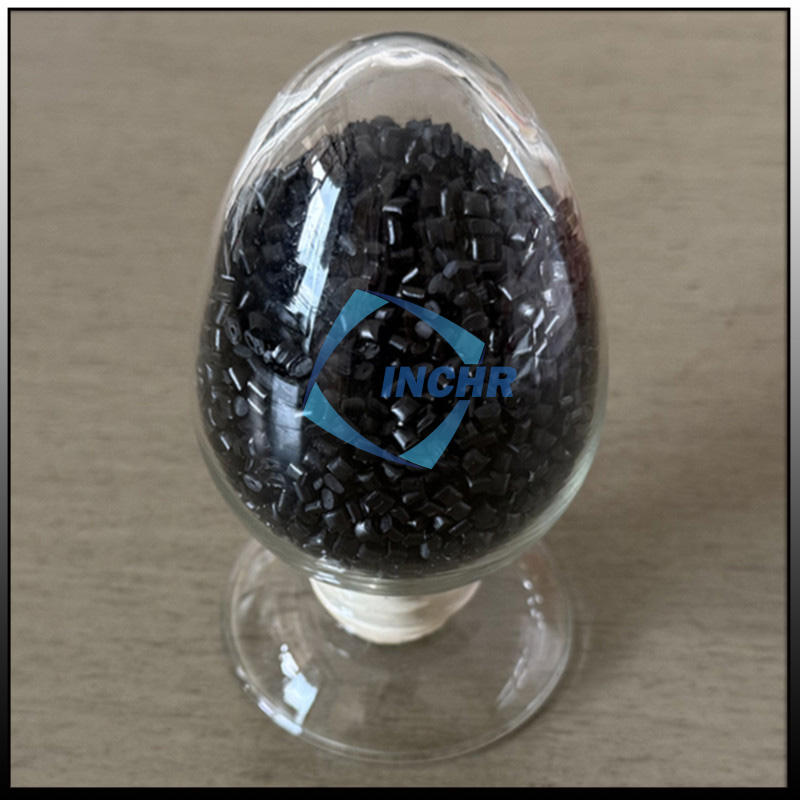

Carbon Fiber models in carbon fiber reinforced nylon generally include short fiber and long fiber:

- Short fiber method: short carbon fiber and nylon are mixed and then extruded and pelletized.

- Long fiber method: Carbon fiber and nylon enter the twin-screw extruder from different positions. Nylon is mixed with additives and then added to the hopper. Carbon fiber is continuously brought into the screw from the carbon fiber inlet through screw rotation.

We reinforce and modify different nylons, including nylon 6, nylon 66, nylon 12, nylon 46 and PPA. We can also use different contents of carbon fiber reinforcement, 10%, 15%, 20%, 30%, 40% carbon fiber reinforced,these grades are common.The carbon fiber content will affect the performance of carbon fiber reinforced nylon. The bending strength, bending elastic modulus, impact strength and plane shear strength of continuous carbon fiber reinforced nylon composite materials increase with the increase of carbon fiber content.

Compared with other carbon fiber materials, carbon fiber reinforced nylon has the following advantages:

- Excellent mechanical properties: carbon fiber reinforced nylon has high strength, hardness and modulus, while maintaining a certain degree of toughness.

- Good wear resistance: It has high surface hardness and excellent wear resistance, and is suitable for applications in abrasive environments.

- Light weight: carbon fiber reinforced nylon has a lower density and is lighter than traditional metal materials, helping to reduce the weight of the product.

- Good processing performance: This material can be processed by common processing methods such as injection molding and extrusion. It is easy to process and the cost is relatively low.

- Chemical corrosion resistance: carbon fiber reinforced nylon has good corrosion resistance to many chemical substances and can be used in harsh environments.

- Good electrical conductivity: It can be modified as needed to make it have certain electrical conductivity to meet specific application requirements.

- Recyclable:The discarded carbon fiber reinforced nylon products are crushed and sorted to obtain reusable carbon fiber and nylon materials.

However, different carbon fiber materials may have their own advantages in specific applications, and factors such as performance, cost, and processing difficulty must be comprehensively considered when selecting.