Introduction of electrical conductive plastic

Electrically conductive plastics are functional polymer materials mixed with resin and conductive substances and processed using plastic processing methods. It is mainly used in electronics, integrated circuit packaging, electromagnetic wave shielding, and other fields.

To impart conductivity to a polymer, a π conjugated system must be added to the main chain in the polymer to form a new polymer with overlapping π electron systems. Moreover, the regular structure of the polymer is also indispensable, and dopants are sufficient and qualified for this task. Therefore, the first condition for a plastic material to be conductive is that it must have a conjugated π electron system, and the second condition is that it must be chemically or electrochemically doped, that is, the polymer chain is gained or lost through a redox process. With the continuous development of technology, the performance of electrical conductive plastics continues to improve, and its application prospects are becoming more and more broad.

Classification of electrical conductive plastic

Electrical conductive plastic materials are typically divided into structural conductive plastics and compounding conductive plastics.

Structural electrical conductive plastics, also known as intrinsic conductive plastics, refer to plastics that are conductive themselves or become conductive after chemical modification. Common polymer conductive materials of this type of material mainly include conjugated polymers, such as polyacetylene, (Sr)n, linear polyphenylene, layered polymers, etc.; metal chelates, such as polyketone phthalocyanine; Charge-shifting polymer complexes, such as polycations and CQ complexes.

Compounding conductive plastic is a functional compound mixed with resin and conductive substances and processed using traditional plastic processing methods. In composite conductive plastics, the plastic itself is not conductive and only acts as an adhesive. Conductivity is obtained by mixing conductive substances such as carbon black, metal powder, etc. These conductive substances are called conductive fillers, with silver powder and carbon black used most commonly. Compounding conductive plastics are easy to prepare and have strong practicability. They are often used in switches, pressure-sensitive components, connectors, antistatic materials, electromagnetic shielding materials, resistors, and solar cells.

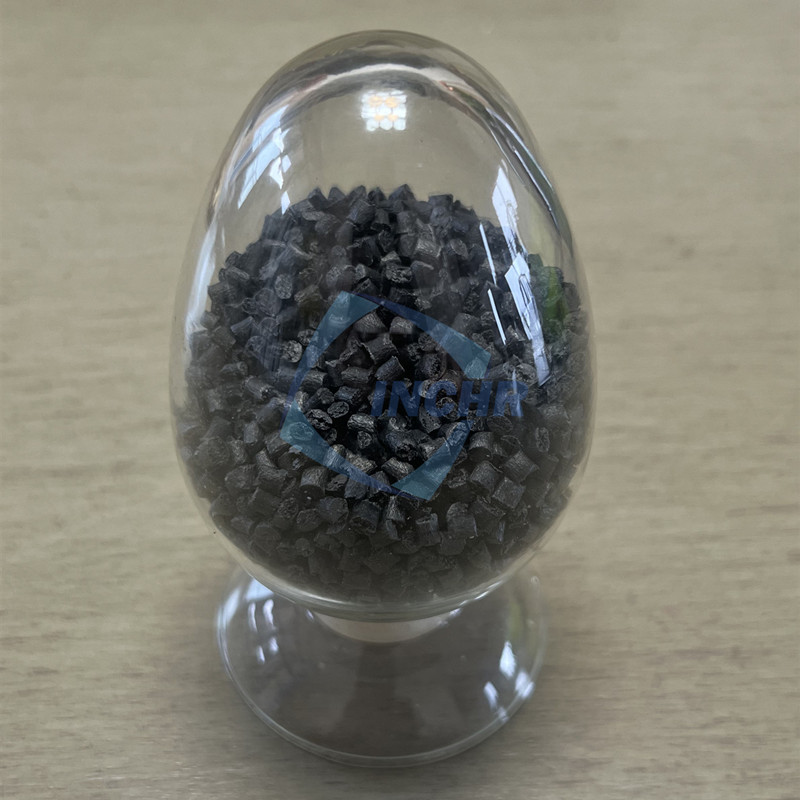

Typical INCHR@Electrical conductive plastics on the market

- Conductive Polystyrene (PS) compound: An electrically conductive plastic widely used in the electronics industry, such as cards, optical fibers, conductive plates, and other fields.

- Conductive Polypropylene (PP) compound: It is an extremely high-performance electrical conductive material that can withstand high temperatures and high pressures and has good chemical resistance. It is often used in high-demand fields such as electronic products, chips, and semiconductors.

- Conductive Polycarbonate (PC) compound: It has good mechanical strength and good heat resistance, and is widely used in fields such as LED TVs, computer screens, cameras, and mobile phone displays.

- Conductive PVC compound: It has excellent conductive properties, crystal properties and mechanical strength, good stability, and processability, and is often used in electronic fields such as LCDs, wearable devices, and smartphones.

- Condcitve Polytetrafluoroethylene (PTFE) compound: A material that is conductive and anti-corrosion, has high chemical resistance and heat resistance, and also has excellent mechanical properties. It is used in semiconductors, chemicals, automobiles, medical equipment, and machinery It is widely used in parts and other fields.

- Carbon fiber reinforced plastics(CFRP): A new material composed of carbon fiber and resin. It has excellent mechanical strength and corrosion resistance, as well as good electrical conductivity and plasticity. It is used in high-end industrial products such as automobiles, aircraft, and ships. , sports equipment and other fields are widely used.

Common processing methods for INCHR@Electrical conductive plastic

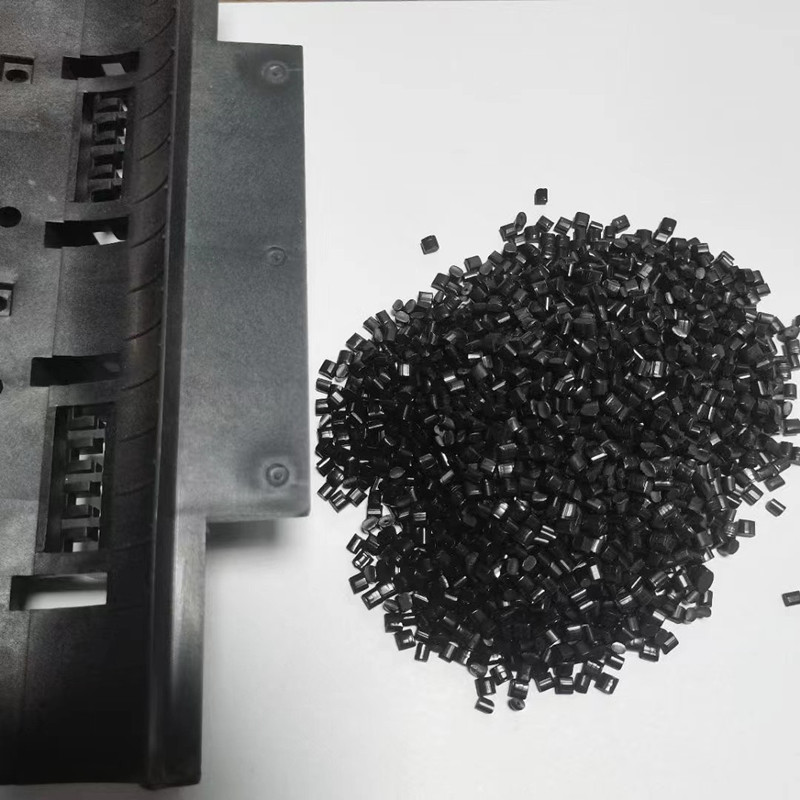

Injection molding: The electrical conductive plastic particles are heated to a molten state, and injected into the mold cavity under high pressure, and the desired shape is obtained after cooling and solidification. This process can form products of complex shapes simultaneously, with high production efficiency and stable product quality. It is suitable for large-scale production of various conductive plastic parts, such as housings and connectors of electronic equipment.

Extrusion molding: The electrical conductive plastic particles are plasticized in the extruder and continuously extruded through a die of a specific shape to produce products with constant cross-sectional shapes such as pipes, bars, and plates, such as those used to manufacture conductive plastic pipes and electromagnetic shielding strips. Extrusion molding products have high dimensional accuracy and good surface quality, and the production process is continuous and efficient.

Blow molding: First, the conductive plastic particles are made into a tubular parison, then placed in a blow molding mold, and compressed air is introduced to expand it and fit the mold cavity. After cooling and finalization, hollow plastic products such as conductive plastic containers, pots, and barrels are obtained. This process can produce hollow products with complex shapes, and the products have good antistatic and electromagnetic shielding properties.

Compression molding: Put a certain amount of conductive plastic into the mold and shape them by heating and pressurizing. This process can manufacture large, thick-walled conductive plastic products, such as conductive plastic plates, block-shaped electromagnetic shielding materials, etc. The product has good density and performance uniformity, but the production efficiency is relatively low and the mold cost is high. It is often used for occasions with high requirements on product performance and size.