In high-performance materials, injection-molding grade carbon fiber reinforced composites are driving the manufacturing industry towards lightweight and high efficiency with a revolutionary attitude. From aerospace to the automotive industry, this material has become the “new favorite” of modern industry with its excellent performance and convenient processing advantages. This article will conduct an in-depth analysis of its core characteristics, process points, and industry benchmark companies.

What is injection-molding grade carbon fiber reinforced composite? | Product Catalog

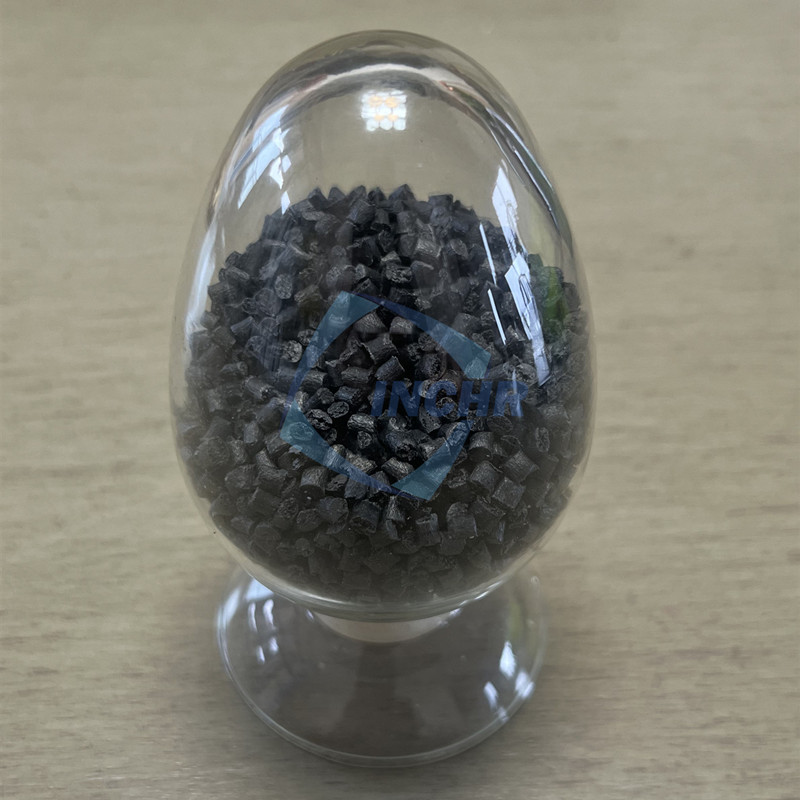

Injection-molding grade carbon fiber reinforced composite (CFRTP) is a high-performance material made of short-cut or long-cut carbon fiber as a reinforcement and compounded with thermoplastic resin (such as PA6, PP, PEEK, etc.). Through a special process, carbon fiber is evenly dispersed in the resin matrix to form granules, which not only retain the high strength and high modulus characteristics of carbon fiber but also have the advantages of thermoplastic resin that can be melt-processed and quickly formed. Compared with traditional thermosetting CFRP, injection-molding grade CFRTP can be directly molded by an injection molding machine, which greatly shortens the production cycle and is suitable for large-scale industrial production.

Excellent mechanical properties: Carbon fiber design with different contents

- Ultra-high strength and lightweight: The addition of carbon fiber increases the tensile strength of the material by 3-5 times, but the density is only 1/5 of that of steel. For example, the weight of automobile chassis parts can be reduced by 40% after using this material, and the impact resistance is significantly enhanced.

- Excellent fatigue and wear resistance: The carbon fiber reinforced structure effectively disperses stress and reduces cracks, and is suitable for parts that bear alternating loads for a long time; the improved wear resistance extends the product life several times, such as gears and bearings.

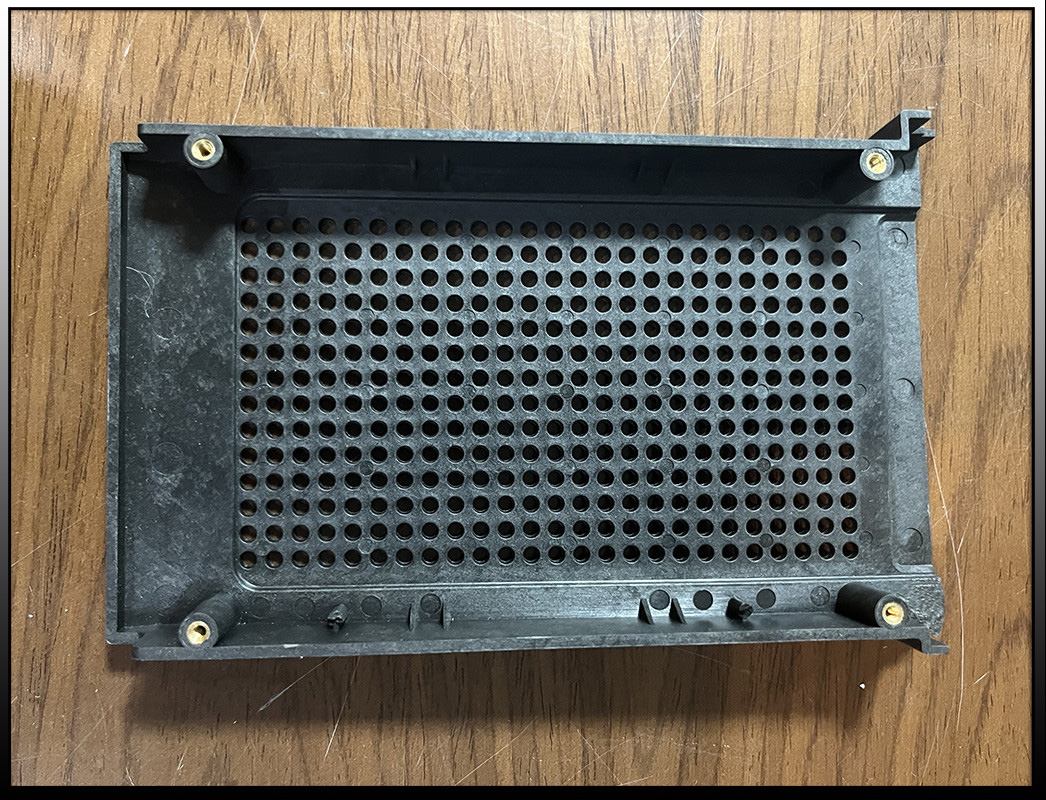

- Dimensional stability and temperature resistance: The thermoplastic resin matrix combined with the rigidity of carbon fiber enables the material to maintain precise dimensions in high-temperature environments, meeting the stringent requirements of electronic equipment and precision instruments.

Processing technology and mold design: Key control from pellets to finished products

Raw material pretreatment

Injection-grade CFRTP pellets need to be fully dried to avoid bubbles or surface defects caused by moisture; adjust the carbon fiber content (usually 5% – 60%) and fiber length according to product requirements.

Injection molding parameter optimization

Temperature control: The resin needs to be heated to a molten state. Too high a temperature will cause oxidation and degradation of the carbon fiber, while too low a temperature will affect fluidity;

Injection pressure and speed: High pressure ensures that the material fills the mold details, and high-speed injection can reduce uneven fiber orientation;

Cooling rate: Rapid cooling can shorten the molding cycle, but it is necessary to prevent internal stress from causing warping and deformation.

Post-processing process: Eliminate internal stress and improve dimensional stability through annealing; surface treatment (such as spraying and coating) enhances aesthetics and functionality.

Key points of mold design

Matrix selection: Use high-hardness, wear-resistant mold steel (such as H13) to prevent carbon fiber from cutting and wearing the mold;

Runner and gate design: Optimize the runner shape to reduce material flow resistance; the gate position should avoid fiber agglomeration or short shot;

Cooling system: Design an efficient cooling water circuit to ensure uniform mold temperature and shorten cooling time;

INCHR@Carbon fiber reinforced composites: Brand advantage of industry benchmark

As a leading enterprise in the field of injection-grade carbon fiber reinforced composites, INCHR sets an industry benchmark with technological innovation and quality service:

- Technical R&D strength: It has independently developed carbon fiber surface treatment technology, which improves the comprehensive performance of materials by more than 20% by optimizing the fiber-resin interface bonding force;

- Full-process production capacity: covers the entire industrial chain from raw material modification, and pellet production to product injection molding, and strictly controls quality stability;

- Precision manufacturing and customized services: equipped with high-precision injection molding equipment and intelligent detection systems, supporting customers’ one-stop customization needs from material formulation to mold design;

- Quality certification and industry reputation: The products have passed international certifications such as ISO 9001 and IATF 16949, and are widely used in high-end fields such as automobiles and aerospace;

- Sustainable development concept: Develop recyclable and low-energy injection-grade CFRTP products to promote green manufacturing and circular economy.

From material performance to process innovation, injection-grade carbon fiber reinforced composites are reshaping the future of modern manufacturing with an unstoppable trend. INCHR relying on its profound technical accumulation and service capabilities, continues to provide leading solutions for the industry and lead the application of high-performance materials to a new level.