In the relentless pursuit of stronger, lighter, and more durable materials, one composite stands out: Carbon Fiber Reinforced Polymer (CFRP). This remarkable engineered material is no longer confined to aerospace labs or Formula 1 garages; it’s rapidly transforming industries from automotive and construction to renewable energy and consumer goods. But what exactly is CFRP, and why is it causing such a revolution?

Deconstructing Carbon Fiber Reinforced Polymer: Strength from Synergy

At its core, CFRP is a composite material. Think of it as a powerful teamwork exercise on a microscopic scale:

The Reinforcer: Carbon Fiber. These incredibly thin strands, thinner than a human hair, are made almost entirely of carbon atoms arranged in crystalline structures. This gives them exceptional tensile strength – they resist being pulled apart far better than steel, gram for gram. Crucially, they are also extremely lightweight and possess high stiffness.

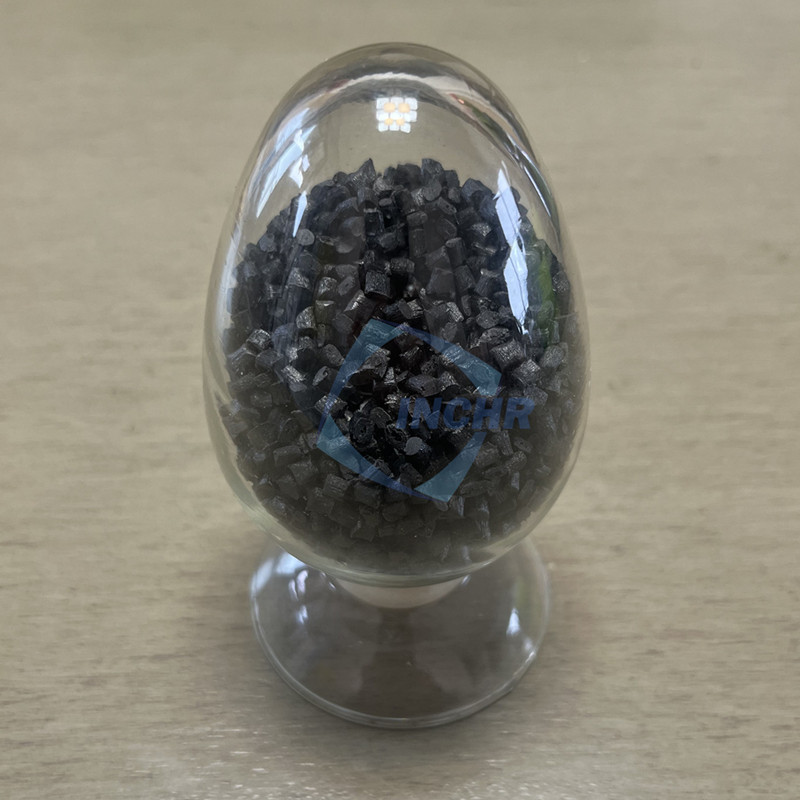

The Matrix: Polymer Resin. Usually an epoxy, polyester, vinyl ester, or nylon, the resin binds the carbon fibers together. It protects the fibers, transfers loads between them, and determines the composite’s final shape, environmental resistance, and overall toughness.

The magic happens when these components are combined. The strong, stiff carbon fibers carry the primary loads, while the polymer matrix holds them in alignment, distributes stress, and shields them from damage. The result is a material exhibiting properties far superior to its individual parts or many traditional materials.

The Manufacturing Process: From Fibers to Form

Creating CFRP components isn’t like casting metal. It’s a precise, often multi-stage process:

Preforming: Carbon fiber sheets (woven fabrics, unidirectional tapes, or chopped fibers) are cut and shaped into a preform resembling the final part.

Layup: The preform is placed into a mold. Multiple layers might be stacked in specific orientations to optimize strength in critical directions.

Impregnation: The resin is introduced. This can happen before layup (prepregs) or during molding (e.g., resin infusion, RTM).

Curing: The resin undergoes a chemical reaction (cured), typically under heat and pressure (in an autoclave or oven), hardening into a rigid matrix around the fibers.

Finishing: The cured part is removed from the mold, trimmed, and may undergo surface treatment or painting.

The Compelling Advantages: Why Carbon Fiber Reinforced Polymer Wins

The unique structure of CFRP delivers a constellation of benefits:

Exceptional Strength-to-Weight Ratio: This is CFRP’s crown jewel. It can be 5 times stronger than steel yet only one-third the weight, or significantly lighter than aluminum while offering comparable or superior strength. This translates directly into fuel savings, increased payloads, and enhanced performance.

High Stiffness: CFRP components resist bending and deformation under load exceptionally well, crucial for structures requiring precision and stability.

Outstanding Fatigue Resistance: CFRP withstands repeated loading cycles much better than metals, leading to longer service life in dynamic applications like aircraft wings or suspension components.

Superior Corrosion Resistance: Unlike metals, CFRP is immune to rust and highly resistant to chemicals and harsh environments, reducing maintenance costs.

Design Freedom: The ability to tailor fiber orientation and layer placement allows engineers to optimize strength exactly where needed, enabling complex, integrated shapes difficult or impossible with metals.

Low Thermal Expansion: CFRP expands and contracts very little with temperature changes, important for precision instruments and structures exposed to varying climates.

Where Carbon Fiber Reinforced Polymer Shines: Real-World Applications

CFRP’s unique properties make it indispensable across diverse sectors:

Aerospace: Dominating modern airframes (Boeing 787, Airbus A350), wings, tail sections, and interior components for massive weight savings and fuel efficiency.

Automotive & Motorsport: High-performance vehicles use CFRP for monocoques, body panels, driveshafts, and suspension components to enhance speed, handling, and safety. Adoption in mainstream EVs is growing for battery enclosures and structural parts to offset battery weight.

Wind Energy: Enormous CFRP turbine blades are lighter, stiffer, and longer than ever, capturing more wind energy efficiently and enabling taller towers.

Construction & Infrastructure: CFRP sheets and strips are used for seismic retrofitting of bridges and buildings. Prestressed CFRP tendons offer corrosion-free alternatives to steel in concrete. Lightweight architectural elements are also emerging.

Sporting Goods: Bicycles, tennis rackets, golf clubs, fishing rods, and hockey sticks leverage CFRP for optimal performance and feel.

The Future & Challenges

While CFRP is transformative, challenges remain. Cost is still higher than traditional metals, primarily due to energy-intensive fiber production and complex manufacturing. Recycling end-of-life CFRP is technically difficult and not yet widespread, though research into pyrolysis, solvolysis, and mechanical recycling is intense. Impact damage tolerance can be lower than metals, requiring careful design. Repairability also requires specialized techniques.

However, the future is bright. Innovations focus on:

Lower-Cost Fibers & Processes: Developing more efficient production methods and alternative precursors.

Advanced Recycling: Establishing viable, large-scale recycling ecosystems.

Hybrid Structures: Intelligently combining CFRP with metals or other composites for optimal performance and cost.

Multifunctional Composites: Integrating sensors or other functionalities directly into the CFRP structure.

Bio-Based Resins: Exploring sustainable polymer matrices.

Conclusion

Carbon Fiber Reinforced Polymer is more than just a high-tech material; As manufacturing costs decrease and recycling solutions mature, CFRP’s role will only expand, moving from high-end niche applications towards becoming a mainstream material powering a lighter, stronger, and more efficient future. From the skies to the roads and our cities, CFRP is truly the lightweight giant shaping the world around us.

https://www.inchr-esd.com/carbon-fiber-reinforced-polymer-lightweight-powerhouse-explained/