Imagine a critical semiconductor component, worth thousands of dollars, rendered useless in an instant. A microscopic spark, invisible and silent, leaps from a technician’s hand or a plastic fixture, frying delicate circuits. This isn’t science fiction; it’s the costly reality of electrostatic discharge (ESD) in advanced manufacturing. For industries where precision and reliability are paramount, selecting materials with inherent, reliable antistatic properties isn’t just beneficial – it’s essential. This is where ESD PEEK (Polyether Ether Ketone) emerges as an engineering plastic superstar.

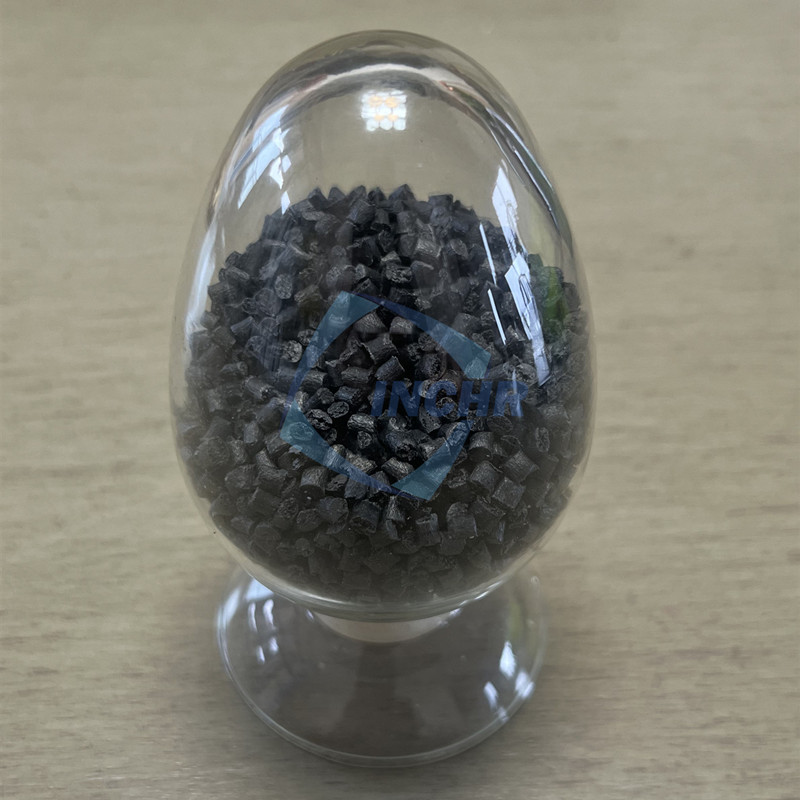

Unlike standard PEEK polymer, renowned for its exceptional thermal stability, chemical resistance, and mechanical strength, ESD PEEK incorporates specialized conductive fillers or modifiers. These additives create a continuous pathway within the polymer matrix, allowing static charges to dissipate safely and continuously to ground, rather than building up to dangerous levels. This transforms PEEK from a potential static generator into a vital safeguard.

Why “Antistatic” Alone Isn’t Enough: The ESD PEEK Advantage

Many plastics offer surface treatments or temporary antistatic agents. These solutions often wear off with cleaning, handling, or exposure to environmental factors. ESD PEEK, however, provides permanent, bulk conductivity. This fundamental difference delivers crucial benefits:

Permanent Protection: The antistatic performance is an intrinsic property, unaffected by wear, washing, or time. It lasts the lifetime of the component.

Consistent Performance: Surface resistance values (typically in the range of 10^4 to 10^11 ohms/square for ideal ESD control) remain stable across the material’s entire operating temperature range (often exceeding 250°C / 482°F) and in various environments, including exposure to aggressive chemicals or solvents where coatings would fail.

Uncompromised Core Properties: High-quality ESD PEEK compounds retain the exceptional characteristics engineers rely on:

High-Temperature Performance: Maintains strength and dimensional stability where most plastics fail.

Superb Chemical Resistance: Withstands harsh solvents, acids, and bases critical in semiconductor processing and chemical handling.

Outstanding Mechanical Strength & Wear Resistance: Ideal for demanding applications like wafer handling claws, bearing cages, and robotic components.

Dimensional Stability & Low Outgassing: Essential in vacuum environments (e.g., semiconductor fabrication, aerospace) and cleanrooms to prevent contamination.

Precision Machinability: Like standard PEEK, ESD PEEK can be precisely machined into complex, tight-tolerance parts essential for sensitive equipment.

Critical Applications Demanding ESD PEEK

The unique combination of permanent ESD protection and high performance makes ESD PEEK indispensable in sectors where failure is not an option:

Semiconductor Manufacturing: Wafer carriers (FOUPs/FOSBs), test sockets, probe cards, robotic end effectors, vacuum chamber components. Preventing ESD damage during chip fabrication and testing is critical for yield.

Electronics & Microelectronics: Handling trays, test fixtures, connectors, insulators within sensitive devices. Protects components during assembly, testing, and operation.

Medical Devices: Components for sensitive diagnostic equipment (e.g., MRI, CT scanners), surgical tools, and implantable device manufacturing equipment. Prevents interference and protects sensitive electronics.

Aerospace & Defense: Housings, connectors, and components within avionics and guidance systems where reliability in harsh conditions is paramount.

Industrial Automation: Gears, bearings, seals, and guides in machinery operating in potentially explosive atmospheres (ATEX) or handling sensitive electronic assemblies.

Beyond Prevention: The Tangible Value of ESD PEEK

Specifying ESD PEEK is an investment in reliability, safety, and cost efficiency:

Protect Sensitive Electronics: Eliminate catastrophic ESD failures, reducing scrap rates and warranty claims.

Ensure Process Reliability: Prevent unexpected downtime caused by static-related malfunctions or contamination in automated processes.

Enhance Personnel & Facility Safety: Mitigate fire or explosion risks in flammable environments caused by static sparks.

Reduce Total Cost of Ownership: The longevity and reliability of ESD PEEK parts, combined with reduced failure rates, often lead to significant savings over cheaper, less reliable alternatives requiring frequent replacement or causing production losses.

Conclusion: The Essential Safeguard for Advanced Engineering

In the high-stakes world of modern electronics, semiconductor fabrication, and advanced manufacturing, static electricity is an invisible enemy. Standard plastics, even high-performance ones like PEEK, can become liabilities without inherent ESD protection. ESD PEEK provides the vital, permanent solution: integrating robust, reliable static dissipation directly into a material renowned for its exceptional thermal, chemical, and mechanical properties. When failure due to ESD is unacceptable, specifying ESD PEEK isn’t just a material choice – it’s a fundamental strategy for ensuring product integrity, operational safety, and long-term success. For engineers designing the next generation of sensitive equipment, ESD PEEK is the intelligent foundation for truly ESD-safe environments.