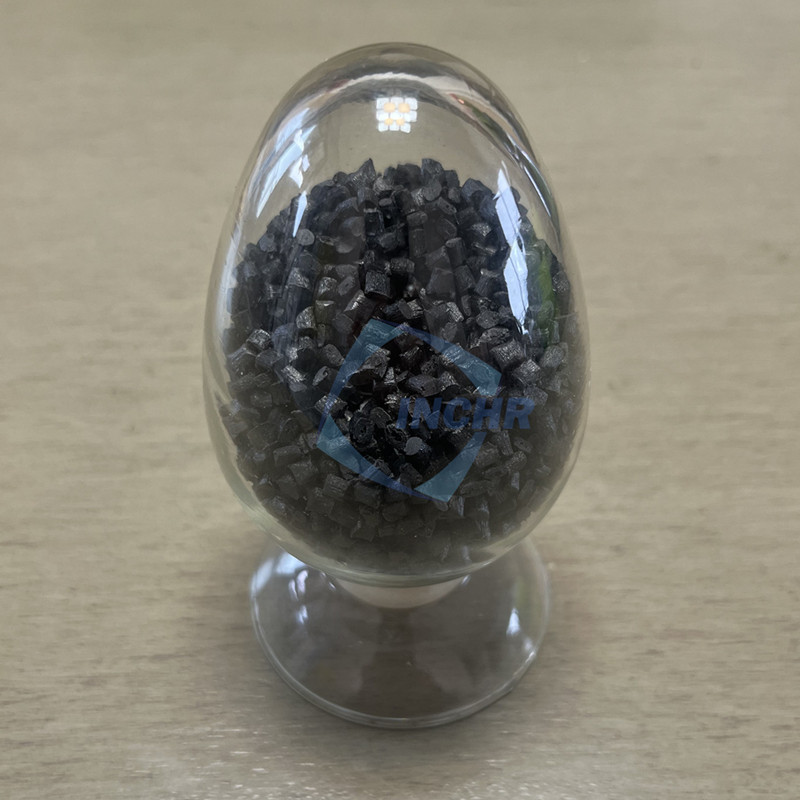

Introuduction of INCHR@ Conductive masterbatch | Product Catalog

A conductive masterbatch in the polymer is a compound formulated with carbon black, carbon nanotubes, or graphene to meet ESD protection requirements and achieve discharge electrostatically. The conductive filler of carbon black-type conductive masterbatches is carbon black which is one of the most versatile functional fillers for ESD plastics, it always provides electrical conductivity to conductive masterbatches for ESD protection. Carbon blacks also function as a moderately low-cost pigment, producing various shades of black on the end product, it can be combined with multiple carrier resins, such as ABS, HIPS, PP, PE, POM, PC, and PA, to produce the conductive compound. Carbon nanotube-type masterbatches and graphene-type conductive masterbatches can be used in high-purity applications and have virtually no effect on shrinkage or mechanical properties compared to carbon black-type conductive masterbatches. Carbon Nanotubes are hollow structures consisting of graphene cylinders of carbon atoms capped at both ends. Carbon nanotube-type and graphene-type masterbatches provide low surface resistivity at a very low loading level.

Conductive masterbatch for HIPS ABS sheet

The conductive masterbatch is based on polystyrene resin as a carrier, formulated with carbon black and carbon nanotubes. The conductive masterbatch offers ideal electrostatic discharge protection with SR of 10E2-10E4 Ohms/sq. This masterbatch can be dry mixed according to the proportion and then extruded into sheets. The recommended addition amount is 40%-60%, and it can also be used as a conductive compound.

Conductive masterbatch for LDPE HDPE

The conductive masterbatch is based on PE resin as a carrier, formulated with carbon black, it can achieve anti-static, static dissipative, anti-dust, conductive electromagnetic interference (EMI) shielding, and other functions. This conductive masterbatch is developed for use in highly flexible plastic tubes and offers very high flexural fatigue strength and high elongation at break. The conductive masterbatches offer ideal electrostatic discharge protection with SR of 10E3-10E5 Ohms/sq.

Conductive masterbatch for PP Sheet

This conductive masterbatch is based on PP resin as a carrier, which is formulated with carbon black, and it can prevent polymers from decomposition when molded or extruded. The masterbatch offers ideal electrostatic discharge protection with SR 10E2 – 10E6 Ohms/sq. This masterbatch offers decay rates measured in nanoseconds, instant enough to provide a ground pathway and bleed off stronger electrical charges. The conductive masterbatch is suitable for extrusion processing and manufacture of ESD PP sheets.

Conductive masterbatch for PC

It is made of PC resin as a carrier and carbon nanotubes. This conductive masterbatch is suitable for plastic products with anti-static, static dissipative, dust-proof, conductive electromagnetic interference (EMI) shielding and other properties. The SR of the conductive masterbatch is 10E4-10E5 Ohms/sq. It can be added in proportion and then injection molded. It is a high-performance and cost-effective conductive masterbatch.

CNT-reinforced conductive masterbatch

300CNT is a conductive compound with 100% multi-walled carbon nanotubes. It has the advantages of high strength, high toughness, efficient conductivity, electromagnetic shielding, etc. Carbon nanotube masterbatch is well-compatible with a variety of polymer matrices and can be processed into products of various shapes through various molding processes such as injection molding and extrusion to meet the needs of different application scenarios.

Characteristics of conductive masterbatch for polymers

– Range of conductivity from 10^1 to 10^6 Ohms/sq

– Adjustable dosage for antistatic performance.

– Compatible with several matrices.

– Easy to disperse, injection molding, or extrusion.

– All products formulated for RoHS compliance.

Packaging and storage instructions

All grades are delivered dried in sealed packaging (25 kg/ bags) ready to be processed.

All Conductive masterbatch can be stored in their original packaging for at least 12 months without losing their properties.