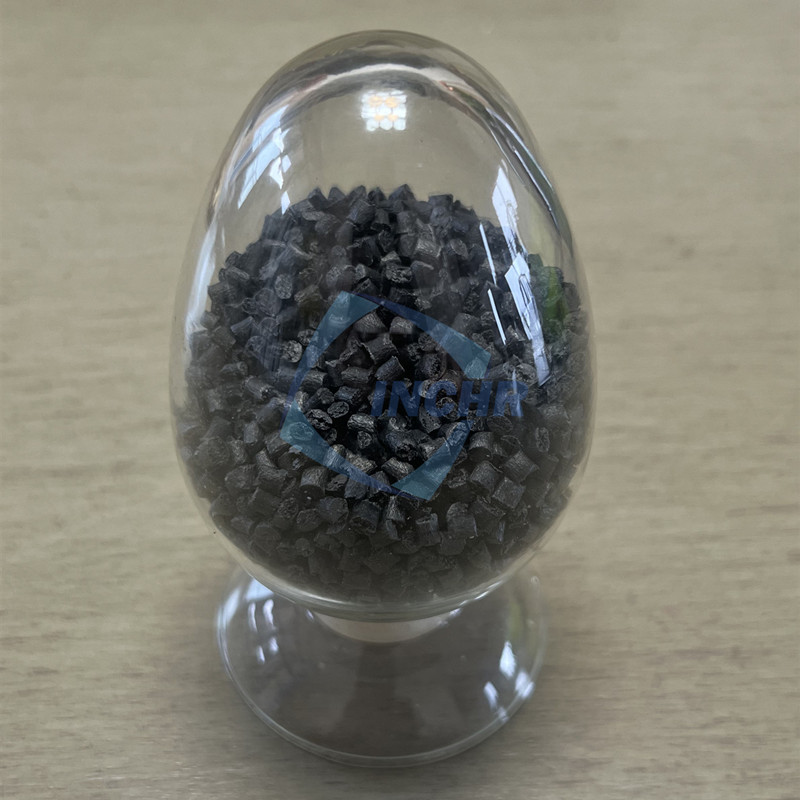

The allure of Carbon Fiber Reinforced Plastics (CFRP) is undeniable: aircraft-grade strength at half the weight of steel. Yet engineers whisper about a dirty secret – crippling anisotropy. While unidirectional CFRP excels in lab tests, real-world multidirectional stresses expose fatal flaws in standard composites. At INCHR-ESD, we engineer CFRP that behaves predictably beyond the datasheet.

The Anisotropy Crisis: 3 Hidden Failure Modes

Cracking Under Off-Axis Loads

Example: A drone arm mold-injected with 30% chopped CFRP fails at motor mounts.

Why: Random fiber orientation creates weak zones (↓60% transverse strength vs. longitudinal).

INCHR-ESD Fix: Hybrid aligned discontinuous fiber (ADF) architecture + reactive tougheners ↑ impact resistance 300%.Matrix-Dominated Creep in Thermoplastics

Example: PA6-CFRP robotic gears deform after 500h continuous operation.

Why: Polymer chains slowly slide under load (↓80% creep resistance vs. thermosets).

INCHR-ESD Fix: Cross-linked PEEK-CF composites maintaining thermoplastic processability with thermoset-like creep resistance.ESD Blind Spots in Conductive CFRP

Example: “Conductive” CFRP semiconductor fixture fails ANSI/ESD S20.20 audit.

Why: Insulative resin pockets between fibers create >10^12 Ω/sq surface islands.

INCHR-ESD Fix:* Plasma-grafted conductive nano-coatings ensuring uniform 10^6 Ω/sq resistivity.

Engineering Isotropic Performance: Our Methodology

Step 1: Fiber Architecture Redesign

| Conventional | INCHR-ESD Solution | Benefit |

|---|---|---|

| Random chopped fibers | 3D-printed continuous fiber paths | ↑ Off-axis strength 90% |

| Unidirectional tapes | ±45° hybrid woven plies | Eliminates shear failure |

Step 2: Matrix Nano-Engineering

Self-Healing Microcapsules: Dicyclopentadiene-filled capsules rupture to repair cracks (<100μm) in epoxy-CFRP.

Graphene Dopants: 0.5wt% graphene in PA66-CF ↓ creep strain by 55% at 80°C.

Step 3: Surface Electromagnetic Control

Z-axis Conductive Channels: Laser-drilled microvias filled with Cu-Ag alloy connect surface to buried fibers.

Anti-Tribocharging Topography: Micro-roughened surfaces (Ra=3.2μm) reduce charge generation by 70%.

Extreme Environment Validation

Case 1: Satellite Antenna Mounts (Geostationary Orbit)

Challenge: -180°C to +150°C cycling → delamination in standard CFRP.

Our Build:

Fibers: M40J high-modulus carbon

Matrix: Cyanate ester-Bismaleimide hybrid

Interface: Silica nanoparticle interphase

Result: Zero CTE mismatch failure after 2000 cycles (ESA ECSS-Q-70-71A certified).

Case 2: Surgical Robot Arms (ISO Class 5 Cleanroom)

Challenge: Static discharge risks + autoclave degradation.

Our Build:

Core: Continuous CF/PEEK

Surface: Atmospheric plasma polymerized pyrrole coating

Result: 10^7 Ω/sq resistivity after 500 steam sterilization cycles.

The Sustainable CFRP Paradox

While virgin CFRP reduces CO2 via light weighting, end-of-life recycling remains problematic. Our closed-loop solutions:

Solvolysis Reactors: Recover undamaged fibers from epoxy CFRP using catalyzed subcritical water (200°C/50bar).

Upcycled CFRP: Shredded aircraft waste → compression molded with vitrimer resins → industrial pallets (↑ strength 200% vs wood).

Why Choose INCHR-ESD CFRP?

Anisotropy Mitigation: ≤5% strength deviation across 0-90° loading angles

ESD Guarantee: Surface resistivity 10^4-10^11 Ω/sq (per ANSI/ESD S20.20)

Traceable Sustainability: Blockchain-tracked recycled content (up to 70%)

inchr-esd.com

Precision-Crafted CFRP Solutions – Where Theory Meets Reality