Carbon Fiber Reinforced Nylon: Unleash Your Creativity With Next-Gen Materials

In a world where innovation thrives on pushing boundaries, traditional materials often limit what’s possible. Heavy metals constrain design flexibility, while basic plastics lack the strength to support bold ideas. Enter Carbon Fiber Reinforced Nylon (CFRN)—a material that not only breaks these barriers but also empowers engineers, designers, and creators to turn visionary concepts into reality. By blending nylon’s versatility with carbon fiber’s unparalleled performance, CFRN is redefining what it means to innovate, offering a playground for creativity across industries.

Why CFRN Is The Ultimate Catalyst For Creative Design

- Design Freedom Without Compromise

CFRN’s unique composition allows for intricate geometries that were once deemed impossible. Unlike metals requiring subtractive manufacturing, CFRN thrives in additive processes like 3D printing (SLS/FDM). Imagine crafting ultra-lightweight drone frames with internal lattice structures or ergonomic medical devices tailored to patient anatomy—all without sacrificing strength. A robotics startup recently designed a bionic gripper with CFRN, achieving 40% weight reduction while doubling gripping precision. - Rapid Prototyping, Faster Innovation

Traditional tooling delays stifle creativity. CFRN bypasses these hurdles by enabling mold-free production. Designers can iterate prototypes in days, not months. For example, a wearable tech company used 3D-printed CFRN casings to test 15 design variations in 3 weeks, accelerating their product launch by 6 months. - Performance That Inspires Bold Ideas

With tensile strength up to 220 MPa and heat resistance exceeding 160°C, CFRN handles extreme conditions that would warp ordinary plastics. This durability lets creators explore uncharted territories—think automotive parts surviving engine heat or outdoor gear enduring harsh climates.

Unlocking Creativity: 4 Industries Transformed By CFRN

- Robotics & Automation: Smarter, Lighter Machines

CFRN’s low inertia and high stiffness make it ideal for robotic arms and AI-driven devices. A factory using CFRN-based collaborative robots saw 30% faster cycle times and 25% lower energy costs, proving that lightweight design boosts both efficiency and functionality. - Consumer Tech: Where Aesthetics Meet Durability

From sleek smartwatch bands to unbreakable phone cases, CFRN merges elegance with ruggedness. A leading audio brand crafted CFRN headphones that are 50% lighter than aluminum versions, enhancing comfort without compromising sound quality. - Sustainable Fashion: Redefining Wearables

Forward-thinking designers are weaving CFRN into eco-conscious apparel and accessories. A luxury brand’s CFRN-reinforced sneaker soles reduced material waste by 60% during production, marrying sustainability with avant-garde style. - Architecture & Art: Structural Artistry

Artists and architects leverage CFRN’s strength-to-weight ratio to create gravity-defying installations. A kinetic sculpture weighing just 8 kg yet spanning 4 meters exemplifies how CFRN turns abstract visions into tangible masterpieces.

CFRN vs. Conventional Materials: Breaking The Mold

| Criteria | CFRN | Aluminum | Standard Nylon |

|---|---|---|---|

| Design Complexity | ★★★★★ (3D-friendly) | ★★☆ (Limited by machining) | ★★★ (Injection molding) |

| Iteration Speed | Days | Weeks | Weeks |

| Weight Savings | 50–70% vs. Metal | — | 20–30% vs. CFRN |

| Environmental Impact | Recyclable thermoplastics | High energy footprint | Moderate |

CFRN’s adaptability and eco-efficiency make it a favorite for creators prioritizing both innovation and sustainability.

How To Harness CFRN For Your Projects: A Step-By-Step Guide

- Start with “What If?” Scenarios

Challenge existing designs: Could a hollow CFRN component replace a solid metal part? Use topology optimization software to explore weight-saving geometries. - Choose the Right Manufacturing Partner

Collaborate with suppliers specializing in CFRN composites. Key parameters to verify:- Carbon fiber content (15–30% for optimal balance)

- Layer adhesion strength (critical for 3D-printed parts)

Brands like BASF Ultramid® and Evonik Vestamid® offer industry-leading CFRN grades.

- Test, Learn, Scale

Validate prototypes under real-world conditions:- Thermal cycling tests (-40°C to 160°C)

- Dynamic load simulations (e.g., 10,000+ stress cycles)

A drone manufacturer achieved FAA certification by stress-testing CFRN propellers in wind tunnels, ensuring reliability at speeds over 120 km/h.

The Future Belongs to the Curious: Are You Ready?

Carbon Fiber Reinforced Nylon isn’t just a material—it’s an invitation to reimagine the impossible. Whether you’re building cutting-edge tech, sustainable products, or revolutionary art, CFRN provides the toolkit to transcend conventional limits.

Ignite Your Creative Journey Today:

- Download our free CFRN Innovation Playbook (includes design templates and case studies).

- Join a webinar with industry experts on “Designing with Advanced Composites.”

- Order a CFRN sample kit to experiment hands-on.

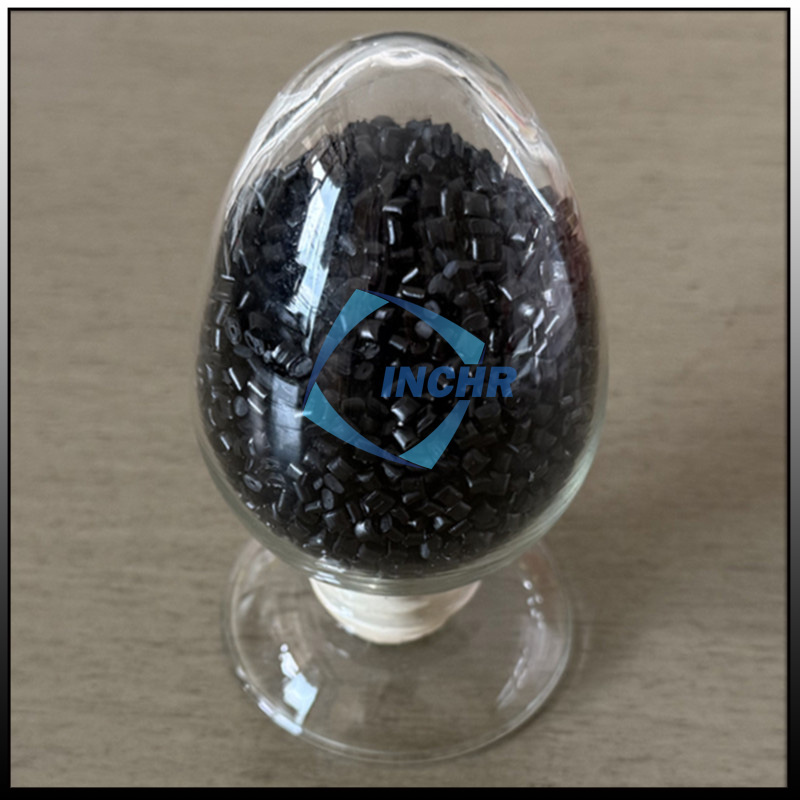

About INCHR

Dongguan City INCHR New Material Co., Ltd. (INCHR) is a manufacturer of carbon fiber reinforced plastic injection molding, providing technical services from material product design and development to industrial large-scale production. INCHR has passed ISO9001 quality system certification and TS16949 automotive industry certification, focusing on carbon fiber composite plastic injection molding grade and conductive antistatic plastic, and has more than ten years of experience in the industry.