Test fixtures are essential for manufacturers of smart electronic products such as smartphones and tablets. They assist in the assembly of electronic products and test their performance. Why are ESD plastics used to make test fixtures?

Protecting electrostatic-sensitive components

- During electronic product assembly and testing, many chips, integrated circuits, etc. are extremely sensitive to static electricity. ESD plastics can be used to make test fixtures’ carrying trays, fixtures and other components to prevent static electricity generated by operators or environmental factors during the test from damaging these components, ensuring the accuracy of test results and the safety of components.

- In motherboard test fixtures for electronic products such as mobile phones and computers, fixed brackets and contact parts made of ESD plastics can prevent static electricity from interfering with and damaging tiny electronic components on the motherboard.

Preventing electrostatic discharge from interfering with test signals

- Test fixtures may generate static electricity when working. If it is not dissipated in time, it will interfere with the test signal and cause inaccurate test data. ESD plastic has good electrostatic dissipation performance and can be used to make the shell and shielding cover of the test fixture, isolating the test area from external static electricity, and quickly conducting the static electricity generated inside to ensure the stability and authenticity of the test signal.

- In the RF test fixture, the shielding structure made of ESD plastic can effectively prevent static electricity from interfering with the RF signal and ensure the accuracy of the RF parameter test.

Realize the dual functions of insulation and electrostatic control

- Some test fixtures require both good insulation performance and the prevention of static electricity accumulation. ESD plastic can maintain a high insulation resistance while having static electricity dissipation capabilities by adjusting the formula and process, meeting the use requirements of the test fixture in different electrical environments.

- In the high-voltage test fixture, the insulating pads and isolation plates made of ESD plastic can withstand high voltages and prevent static electricity accumulation, ensuring the safety of test personnel and equipment.

Reduce the maintenance cost of the test fixture

- Test fixtures made of traditional materials may cause component damage or performance degradation due to static electricity problems, requiring frequent repairs and replacements. ESD plastics can effectively reduce static-related failures, extend the service life of test fixtures, and reduce maintenance costs and downtime.

- In automated test production lines, test fixtures made of ESD plastics can reduce equipment failures caused by static problems, and improve production efficiency and test continuity.

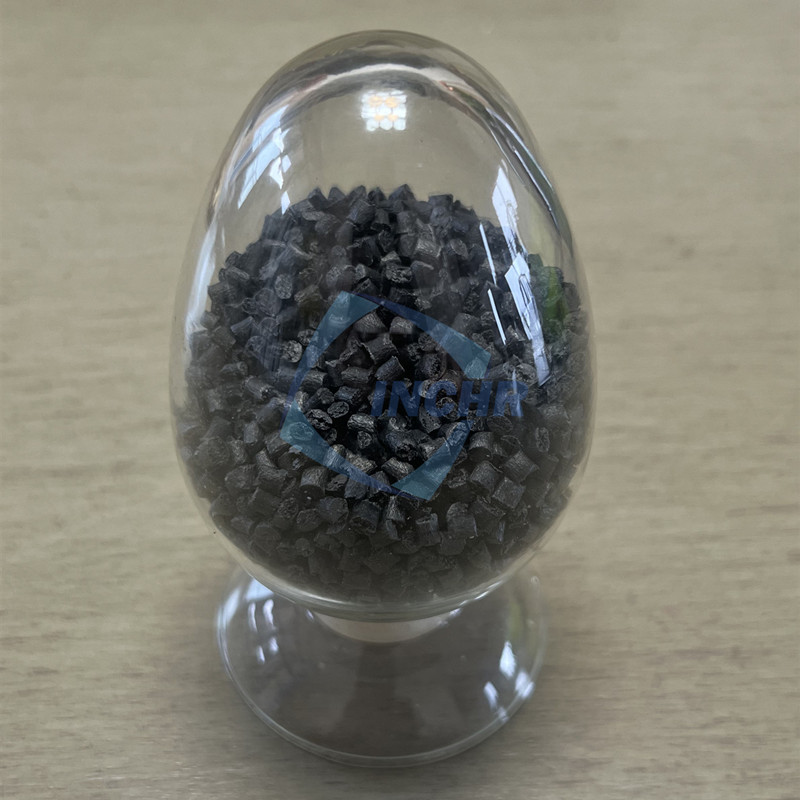

About INCHR

Dongguan City INCHR New Material Co., Ltd. (INCHR) provides a range of ESD plastics to support the production of different test fixtures. INCHR has existing antistatic agents, antistatic masterbatches and conductive masterbatches for customers to add in proportion, and can also customize formulations to meet requirements. It can provide various ESD plastics in natural color, black or color. We have a professional technical team that can communicate with customers effectively and quickly to provide ESD plastics with accurate resistance values according to different processing techniques.