Definition of masterbatch and conductive masterbatch

The definition of masterbatch in processing and molding is to mix and refine various required additives, fillers, and a small amount of resin. The plastic particles obtained after granulation are called masterbatch. The limit of additives in the masterbatch is generally much higher than the required amount in plastic products, usually several times or even ten times higher. Therefore, in the process of using the masterbatch to process products, it is necessary to follow the relevant requirements in the masterbatch. The content of ingredients and the amount required in the product are adjusted to the ratio of conductive masterbatch to resin base material. Masterbatch is usually divided into ordinarily filled masterbatch and functional masterbatch. Functional masterbatch is designed to meet a special function in plastic products, such as color, flame retardancy, conductivity, anti-fog, etc.

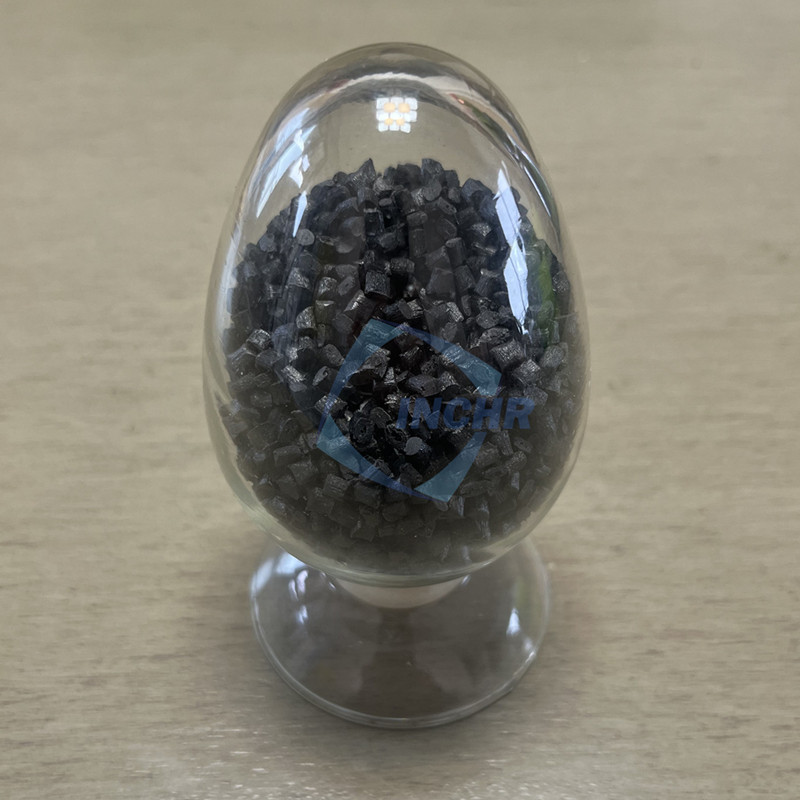

Conductive masterbatch is made by mixing a resin base material with carbon black and other additives. During the processing, the conductive masterbatch is adjusted to a certain ratio with the base material, which can increase the conductivity or anti-static properties of the resin. Adding a conductive masterbatch makes the resin conductive without damaging the mechanical and physical properties of the resin itself. What needs to be paid attention to during the processing is the drying issue, and pre-drying the materials is necessary.

PP conductive masterbatch| Product Catalog

PP conductive masterbatch is made of polypropylene (PP) as the basic material and compounded by adding electrostatic conductive carbon black and other additives. It has good conductive properties and anti-static capabilities, and can effectively prevent the generation and accumulation of static electricity. It also has excellent thermal stability, chemical resistance, and mechanical strength, allowing it to operate stably in various harsh environments.

PP conductive masterbatch is widely used. It can be used to manufacture various products that require anti-static properties, such as conductive packaging boxes, anti-static containers, anti-static cables, etc. In the manufacturing process of electronic devices, static electricity may cause damage to electronic components, and the application of PP conductive masterbatch can greatly reduce this risk and improve the quality and reliability of electronic products. PP conductive masterbatch can also be used for surface coating of plastic products to improve their antistatic properties.

PP conductive masterbatch has many advantages over traditional materials. It has good molding performance and can achieve better molding effects during injection molding, blow molding, and other processing processes. PP conductive masterbatch has high strength and hardness, which can meet various strength requirements and ensure the stability and reliability of the product. PP conductive masterbatch also has good heat resistance and chemical stability and can maintain good performance in harsh environments.

PE conductive masterbatch

PE conductive masterbatch is a kind of plastic particle with conductive properties. It is mainly composed of polymer matrices such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and conductive fillers. It has excellent conductive properties and can be used in electronic products, anti-static materials, lightning protection materials, electronic components, cables, and other fields. PE conductive plastic masterbatch is mainly used in fields such as chips, electronics, integrated circuit packaging, and electromagnetic wave shielding. Such as fuel pipelines; low-resistance plastic packaging trays for electronic products, conductive/anti-static plastic sheets, sheets, and conductive films.

PS conductive masterbatch

PS conductive masterbatch uses superconducting carbon black as a functional additive, PS as matrix resin, good dispersion of self-made coupling agent and dispersant, and is granulated by internal mixer and twin-screw extrusion. It can be used to manufacture PS, HIPS, PPO, and other conductive injection molded products, plates, sheets, and other products, with permanent and stable conductive properties.

The PS conductive masterbatch selects high-quality carbon black with high structure, large specific surface area, high purity, and low impurities as the conductive filler. The one obtained through modification after mixing can be added to ordinary PS polymers to improve the conductivity and anti-static properties, it is a high-performance functional masterbatch, PS conductive masterbatch has good conductive properties, and its performance is not affected by environmental humidity. It can be directly added to PS, HIPS, and PPO resin of different hardness, suitable for injection molding, extrusion, fiber spinning, film blowing, tube extrusion, and other processing techniques.

ABS conductive masterbatch

ABS conductive masterbatch is made of ABS resin as a carrier, and conductive materials such as carbon nanometers and carbon black tubes are added. ABS conductive masterbatch can significantly reduce the surface resistivity of plastic products, making them have good conductive and antistatic properties, and the surface resistivity can reach 10⁴-10⁵ ohms/square.

The conductive material can be evenly dispersed in the ABS resin, ensuring the uniform distribution of the masterbatch in the plastic products, so that the conductive properties of the plastic products are more stable. When added in an appropriate amount, it has little effect on the mechanical properties of ABS plastics, such as impact strength and tensile strength, which can basically maintain the original properties of ABS plastics. It has good thermal stability and chemical stability, and can still maintain stable conductive properties in harsh environments such as high temperature and high humidity. When in use, the ABS conductive masterbatch is mixed with ABS resin in a certain proportion, and then various plastic products are made through injection molding, extrusion, and other processing processes. The mixing ratio will be adjusted according to the specific conductive performance requirements and the application scenarios of plastic products.

The conductive material can be evenly dispersed in the ABS resin, ensuring the uniform distribution of the masterbatch in the plastic products, so that the conductive properties of the plastic products are more stable. When added in an appropriate amount, it has little effect on the mechanical properties of ABS plastics, such as impact strength and tensile strength, which can basically maintain the original properties of ABS plastics. It has good thermal stability and chemical stability, and can still maintain stable conductive properties in harsh environments such as high temperature and high humidity. When in use, the ABS conductive masterbatch is mixed with ABS resin in a certain proportion, and then various plastic products are made through injection molding, extrusion, and other processing processes. The mixing ratio will be adjusted according to the specific conductive performance requirements and the application scenarios of plastic products.

ABS conductive masterbatch can be used to produce various electronic and electrical housings, parts, etc., such as computer monitor housings, printer housings, mobile phone housings, etc., which can effectively prevent the damage caused by static electricity accumulation to electronic components. This masterbatch is used in automotive interior and exterior parts, such as dashboards, seats, bumpers, etc. It can not only meet the conductivity and anti-static requirements of automotive parts but also maintain the good appearance and mechanical properties of ABS plastics. It is also used to produce anti-static packaging materials, such as packaging trays and packaging bags for electronic products, which can protect electronic products from static interference during transportation and storage.