Introduction Of PET ESD Masterbatch 204AN

Introduction Of PET ESD Masterbatch 204AN

- The surface resistance of the 204AN specimen is 10E6-10E7 Ohms, and the addition amount is usually determined according to the specific application requirements and the characteristics of the PET resin. For PET thermoforming film, the recommended dosage level is 2-5%wt to achieve a surface resistivity of 10^8 to 10^11 ohms on PET sheets and BOPET films.

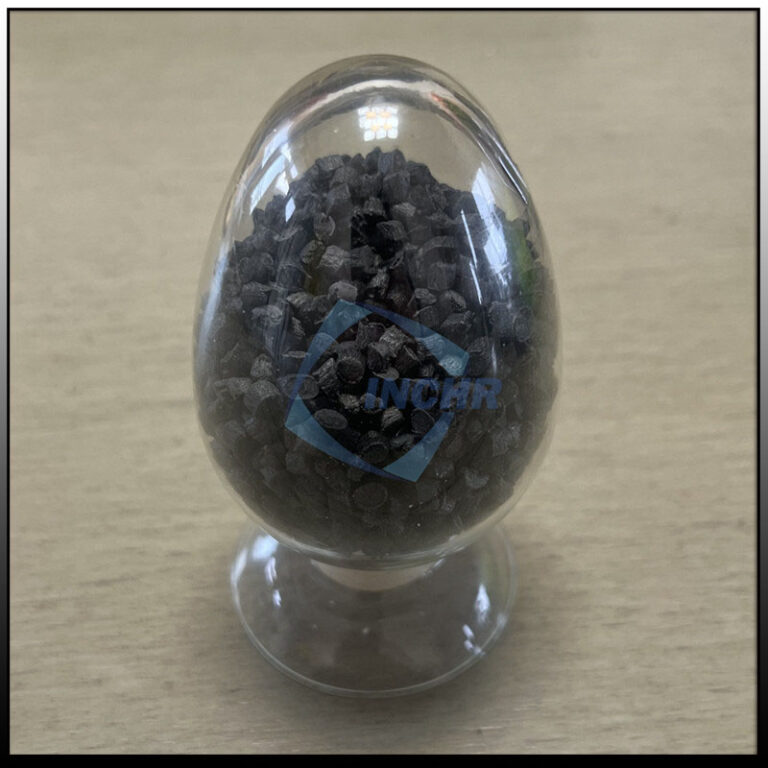

- 204AN is a white uniform columnar particle with a glass transition temperature (DSC) of 60 – 70°C. It significantly reduces the surface resistance of the film; it has good heat resistance and has no effect on the hue of the substrate. It is suitable for PET sheets and BOPET films. PET antistatic masterbatch gives films and sheets good and lasting antistatic properties.

- 204AN is an antistatic masterbatch used to improve the antistatic properties of polyethylene terephthalate (PET) materials. It is composed of antistatic agents, carrier resin, and other additives. It has excellent compatibility with PET crystalline resin and can be evenly dispersed in the PET material to achieve long-term antistatic performance and maintain good transparency.

- Recommended to pre-dry antistatic masterbatch 204AN for 60-90 minutes before processing under the condition of 50-70°C. Because PET is highly hygroscopic, moisture will cause PET to hydrolyze during processing, causing molecular chains to break and molecular weight to decrease, which end up affecting the performance of the end product, such as poor transparency .

Characteristics Of PET ESD Compound 920AN

● Material mechanical properties: 920AN is a polyester-modified ESD compound with antistatic properties. It has good physical properties such as high transparency, high mechanical strength, good chemical resistance, etc. It also has antistatic properties and can effectively prevent static electricity accumulation and discharge.

● Material chemical resistance properties: 920AN has a certain tolerance to common organic solvents such as alcohols, ketones, and esters, such as methanol, ethanol, acetone, ethyl acetate, etc, however, long-term or high-concentration contact may cause changes in material properties It can tolerate a certain concentration of weak acids and weak bases.

● Antistatic performance: The antistatic compound achieves the antistatic effect by adding antistatic masterbatch, conductive masterbatch, etc. PET ESD compound is one of the most widely used antistatic polymers with a surface resistivity of 10E8-10E11 Ohms/sq, providing reliability and value for applications that need to dissipate static charge. PET conductive material has a low surface resistivity of 10E5-10E7 Ohms/sq.

● Processing method: PET ESD compounds can be made into different products through a variety of processing methods, such as films, sheets, tapes, etc. Common processing methods include extrusion molding, stretching molding, coating, etc.

Application Fields Of PET ESD Compound

Application Fields Of PET ESD Compound

ESD PET compounds are polyethylene terephthalate (PET) composite materials with electrostatic discharge (ESD) function, which are widely used in many fields:

Electronic and electrical fields

Used in electronic components and circuit board packaging: used to manufacture trays, carriers, packaging boxes, and other packaging materials for electronic components to prevent static electricity from damaging sensitive electronic components, such as chips, integrated circuits, sensors, etc. during production, transportation and storage, which can effectively avoid problems such as static electricity breakdown. In addition to electronic component packaging, it is also used in the outer packaging of finished electronic products, such as packaging boxes and cushioning materials for electronic products such as mobile phones, computers, cameras, etc., to prevent static electricity from damaging products during transportation and storage.

Optoelectronic field

It is used in the production and packaging process of optical instruments and optoelectronic devices (such as LED devices) to prevent static electricity from absorbing dust and impurities, affecting optical performance and product quality; it can also be used to make protective materials for optical lenses, display screens, etc.

Packaging field

For food and drug packaging (especially food packaging containing electronic sensing tags), ESD PET composite materials can also be used for packaging materials to ensure product quality and safety; PE + PET composite packaging can be used for the packaging of daily necessities, detergents, and other household chemicals, PET provides electrostatic protection, PE provides physical protection and resistance to chemical erosion.

3D printing field

For example, C-PETG jointly launched by Graphmatech and Filalab is a graphene-enhanced ESD wire designed for modern electronic manufacturing. It can be used to make packaging, tools and assembly components in electronic manufacturing. It has a fast printing speed and can produce customized parts within one day. At the same time, it provides reliable electrostatic protection to prevent static electricity accumulation from damaging sensitive electronic components; it can also reduce common defects such as cross-linking, improve printing quality, and achieve more complex designs through better overhang capabilities.