Introduction Of PEEK ESD Compound

Introduction Of PEEK ESD Compound

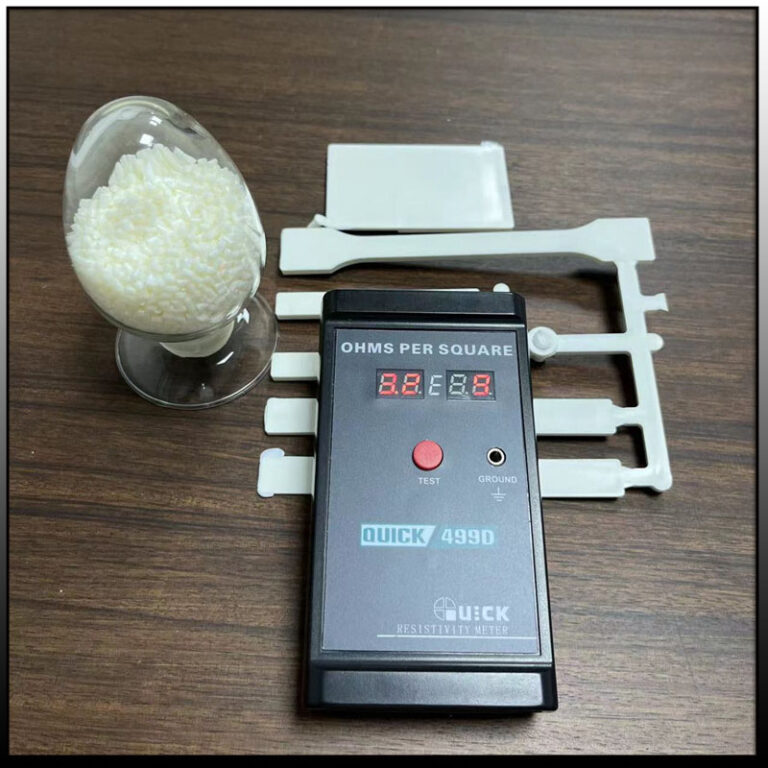

- Conductive PEEK compound is based on PEEK resin and, and formulated with carbon black, carbon nanotubes, or carbon fibers. It can achieve anti-static, conductive, and electromagnetic interference (EMI) functions. The surface resistance of conductive PEEK can be adjusted from the range of 10^3 to 10^8 Ohms.

- 450K is a PEEK ESD compound made of polyetheretherketone (PEEK) as the base material and is compounded by adding special antistatic agents or conductive fillers. It can effectively control the generation and accumulation of static electricity, and prevent electrostatic discharge from damaging sensitive electronic components. 450K has high strength, high rigidity, and excellent mechanical properties, and can withstand greater pressure and tension. This PEEK ESD compound is resistant to high temperatures and can still maintain good performance stability in high-temperature environments. At the same time, 450K has strong chemical corrosion resistance and has a good tolerance to most chemicals.

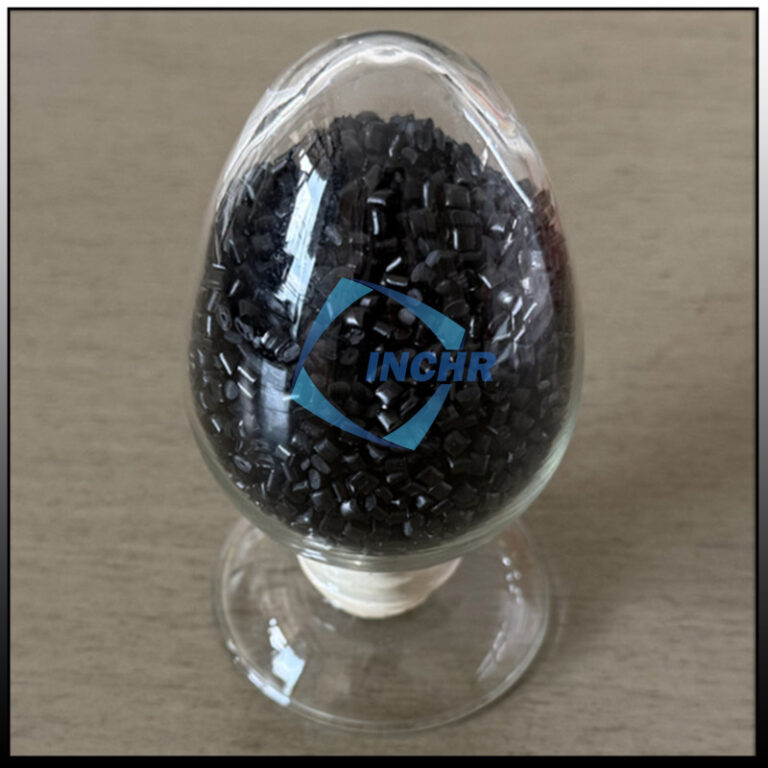

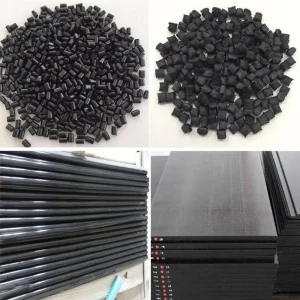

- 450C is a conductive PEEK compound with a regular black solid, hard texture, smooth surface, and density of 1.4-1.45g/cm3. Conductive PEEK has good conductive properties, mechanical strength, high-temperature resistance, chemical resistance and hydrolysis resistance, wear resistance, and friction properties, high creep resistance, good dimensional stability, and UV resistance. It has the characteristics of high-energy radiation resistance, inherent low flammability, and low smoke production when burning.

Applications Of PEEK ESD Compound

- Electronic and electrical field: PEEK ESD compound is used to manufacture the housing, connectors, insulating parts, etc. of electronic equipment, which can prevent static electricity from interfering with and damaging electronic components.

- Aerospace field: It can be used to make parts inside aircraft and spacecraft, meeting anti-static requirements while adapting to harsh working environments.

- Medical field: It is used to manufacture parts of medical equipment to ensure the safety and reliability of the equipment during use, such as gas analyzer structural parts, heat exchanger scrapers, etc.

- Energy battery field: PEEK ESD has become one of the indispensable materials in fuel cells due to its excellent properties such as high-temperature resistance, corrosion resistance, and wear resistance.

- In the semiconductor field: It is mainly used in 300mm chip carriers, CMP retaining rings, wafer suction cups, insulating films, connectors, printed circuit boards, high-temperature connectors, optional electroplating rings, etc.

- Automotive field: PEEK ESD has a lower specific gravity than glass fiber-filled PEEK compounds and provides super strength, which makes antistatic PEEK materials an ideal choice for lightweight parts such as automobiles, sporting goods, robots, drones, and other automation systems.