Introduction Of Antistatic Additive For Plastic PE

Introduction Of Antistatic Additive For Plastic PE

- Antistatic addtive for plastic PE is a ESD additive used in high-density polyethylene (PE). Its main function is to give PE resin permanent antistatic properties. Its composition consists of an antistatic additive and a PE carrier. The antistatic additive is a high molecular polymer with a specific structure that can form a conductive network in the PE resin.

- 80AN is an antistatic additive for plastic PE which iscompatible with HDPE, LDPE, and LLDPE. It is a pellet with a pale yellow color and can be colored easily. The transparent grade is available.

- 300AN is anantistatic additive for plastic PE film. Its main features are a low melt index and good compatibility with LLDPE resin. After compounding ,It forms a conductive layer on the surface of LLDPE film, allowing static charges to be quickly conducted to the ground or other conductive objects, thereby avoiding the accumulation of static electricity.

- 320AN is an antistatic additive for plastic designed for HDPE resin. Its main features are high hardness, small addition amount, and good compatibility. Suitable for various HDPE injection molding parts and HDPE sheets.

Applications Of Antistatic Additive For Plastic PE

- In the electronics industry, permanent antistatic agents are used to package electronic components, circuit boards, semiconductor chips, and other electrostatically sensitive products to prevent static electricity from damaging electronic components and ensure their safety and integrity during transportation and storage.

- In the precision instrument industry, packaging materials made with permanent antistatic agents can effectively prevent static electricity from interfering with instruments and ensure the precision and accuracy of instruments.

- In the pharmaceutical and cosmetic industries, antistatic properties can prevent static electricity from causing dust pollution to medicines and cosmetics and ensure the cleanliness of medicines and cosmetics.

- In automotive parts, optical equipment, aerospace equipment, and other industries, antistatic materials are also widely used to prevent dangerous incidents caused by static sparks and meet various static control needs.

INCHR@Antistatic Masterbatch 350AN

INCHR@Antistatic Masterbatch 350AN

350AN is an antistatic masterbatch based on an antistatic additive for plastic PE, which uses PE resin as a carrier. The unique feature of 350AN is its ease of use. It can be directly injected or extruded after dry mixing with PE resin, unnecessary for compounding. The compatibilizer itself is formulated in the antistatic masterbatch and has little effect on the performance of the matrix. The antistatic masterbatch can form a discharge layer on the surface of the material, thereby reducing its surface resistivity and allowing the static charge that has been generated to leak quickly. The specific addition ratio is determined according to the requirements of the product’s antistatic performance and processing technology.

- The antistatic masterbatch can take effect immediately and provide a long-term antistatic effect.

- It does not migrate, relative humidity has little effect on antistatic performance.

- 350AN is a semi-transparent granular material.It can produce a transparent antistatic compound when using a small dosage.

- It can maintain the mechanical properties of the polymer and has excellent compatibility.

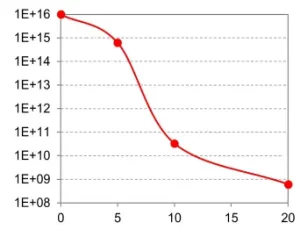

- Extremely effective in providing different performance targets (10E8-10E11 Ohm/sq).