Characteristics Of Carbon Fiber Reinforced Nylon

Characteristics Of Carbon Fiber Reinforced Nylon

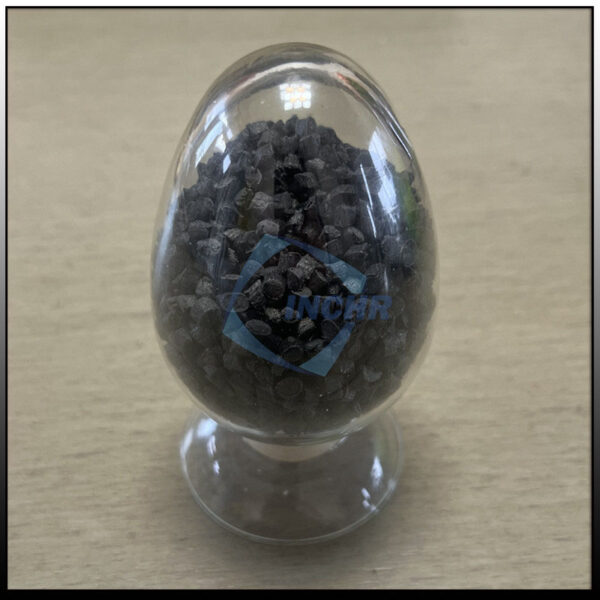

- 70CF20 is a carbon fiber reinforced nylon made of nylon 66 as the matrix and 20% (mass fraction) of carbon fiber as the reinforcement. Compared with traditional metal materials, carbon fiber reinforced nylon has a lower density, which can achieve a lightweight design, reduce product weight, and reduce energy consumption.

- 70CF20 has excellent wear resistance, self-lubricating properties, and high mechanical strength. The addition of carbon fiber greatly improves the tensile strength, bending strength, and impact strength of the material, enabling it to withstand greater external forces. It has a high elastic modulus.

- 70CF20 can maintain strong strength and stiffness at higher temperatures. This carbon fiber reinforced compound is still hygroscopic after molding, the degree of which mainly depends on the composition of the material, wall thickness, and environmental conditions.

- Carbon fiber reinforced nylon can be divided into injection molding grade and extrusion grade according to the processing technology. Carbon fiber reinforced nylon injection molding grade is designed for injection molds, the compounds are injected into the mold, and formed products are obtained after cooling and solidification. The carbon fiber reinforced nylon extrusion grade is heated and melted by the extruder and then extruded into products of various shapes, such as 3D printing filaments, pipes, rods, plates, etc.

- Compared with ordinary nylon, carbon fiber reinforced nylon can still maintain good strength and stiffness at high temperatures, and have a higher heat deformation temperature, making them suitable for components working in higher temperature environments. It has good resistance to chemicals such as acids, alkalis, and salts, and can be used for a long time in harsh environments.

Application Of Carbon Fiber Reinforced Nylon In Civilian Drones

Application Of Carbon Fiber Reinforced Nylon In Civilian Drones

With the rapid advancement of civilian drone technology, it has been widely used in many fields such as aerial photography, environmental protection, meteorological monitoring, and search and rescue. Because civilian drones need to operate in extreme conditions (deserts, low-cold polar regions, rainforests, seashores, etc.), there are extremely high requirements for the performance of each component. Among them, the demand for lightweight and high loads is undeniable. To conquer this problem, INCHR is dedicated to research and development and has launched carbon fiber reinforced nylon and carbon fiber reinforced thermoplastic materials, which can well meet the requirements of flight performance.

Body structure

Civilian drones need to fly in different environments and have higher requirements for the strength and stability of the fuselage. Carbon fiber-reinforced nylon has ultra-high strength and modulus and can withstand complex external forces, vibrations, and impacts during flight, ensuring the stability of the fuselage structure. Its low-density characteristics can significantly reduce the weight of the fuselage and improve flight efficiency and endurance.

Wings and blades

Wings and blades need to generate sufficient lift during flight, which places strict requirements on the strength, rigidity, and fatigue resistance of materials. Carbon fiber reinforced nylon has high strength and rigidity and can withstand huge pressure and inertial force during flight, ensuring the structural integrity and reliability of the wings and blades, and extending their service life. The lightweight characteristics of the material can reduce the moment of inertia, Reduce the energy consumption of the drone’s power system, and improve flight performance and response speed.

Landing gear

The landing gear bears a large impact force when the drone takes off and lands, and needs to have high strength, high rigidity, and good impact resistance. Carbon fiber reinforced nylon can meet these requirements, provide stable support and cushioning for the drone, reduce the impact on the fuselage during takeoff and landing, and ensure flight safety.

Other parts

In some components that require high accuracy and stability, such as UAV flight control system brackets, sensor housings, etc., the good dimensional stability of carbon fiber reinforced nylon can ensure the accuracy and reliability of these components under different environmental conditions, ensuring the accuracy of UAV flight control and data collection.

Given the low density, high modulus, and high requirements for the appearance design and color of drone parts, INCHR provides comprehensive performance analysis. Carbon fiber-reinforced nylon not only exhibits excellent drop resistance and flight stability but also significantly extends its battery life. INCHR’s technical team established a long-term aging test platform for drone blades. In addition, we work closely with our customers to design parts that are easy to assemble and disassemble to achieve an overall improvement in production efficiency.

The higher the carbon fiber content of carbon fiber reinforced nylon, the better the performance ?

The higher the carbon fiber content of carbon fiber reinforced nylon, the better the performance ?

The performance of carbon fiber reinforced nylon does not always improve with the increase of carbon fiber content, but there is a relatively suitable range. It is necessary to select the appropriate carbon fiber content according to the specific application requirements and processing technology. We will explain it in depth from the following aspects.

Mechanical properties

Advantages: Within a certain range, as the carbon fiber content increases, the mechanical properties of carbon fiber reinforced nylon such as strength and stiffness will be improved. For example, the study of chopped carbon fiber reinforced nylon 66 found that with the increase of carbon fiber content, the impact resistance of the material is significantly improved. In addition to the fracture and crack propagation of the nylon matrix during the impact, fiber pullout, and fiber fracture also occurred, but the overall material’s ability to resist impact was enhanced.

Disadvantages: When the carbon fiber content is too high, the mechanical properties of carbon fiber reinforced nylon may decrease. Because too high a carbon fiber content will increase the difficulty of material processing, it is difficult for the carbon fiber to be evenly dispersed in the nylon matrix, and it is easy to agglomerate, causing defects inside the material, thereby reducing the mechanical properties of the material.

Processing performance

Advantages: When the carbon fiber content is moderate, the processing performance of carbon fiber reinforced nylon is better. The addition of carbon fiber can increase the melt viscosity of the material to a certain extent, making it easier to form during the injection molding process, and the dimensional stability of the product is better.

Disadvantages: However, if the carbon fiber content is too high, the melt viscosity of carbon fiber reinforced nylon will increase significantly, and the fluidity will deteriorate, making it difficult to fill the mold cavity during the injection molding process, thereby affecting the molding quality of the product, and may even cause defects such as lack of material and pores in the product.

Other performance aspects

Advantages: Carbon fiber has good wear resistance and corrosion resistance. The appropriate addition of carbon fiber can improve the wear resistance and corrosion resistance of nylon materials and extend the service life.

Disadvantages: When the carbon fiber content is too high, it may affect other properties of the material, such as toughness. A high content of carbon fiber will make carbon fiber reinforced nylon too rigid, reduce toughness, and easily break when impacted or bent.