For engineers and designers pushing performance boundaries, Carbon Fiber Reinforced Polymer (CFRP) isn’t just another material; it’s the cornerstone of a lightweight revolution. This advanced composite, fusing ultra-strong carbon fibers with a polymer matrix (typically epoxy, vinyl ester, or thermoplastic), delivers an unparalleled strength-to-weight ratio – often exceeding steel by 5x while weighing 70% less. But its impact stretches far beyond raw metrics. CFRP is reshaping entire industries, demanding smarter approaches, especially in ESD-critical environments where traditional composites pose unseen risks.

Why Carbon Fiber Reinforced Polymer Dominates Modern Engineering: Beyond the Hype

Unmatched Strength & Stiffness at Minimal Weight: This is CFRP’s signature advantage. Replacing steel or aluminum with CFRP drastically reduces component mass. In aerospace, this translates to extended range and fuel savings (e.g., Boeing 787’s 20% fuel efficiency gain). In robotics and automation, lighter arms enable faster cycle times and reduced motor strain. Even consumer electronics leverage CFRP for durable, feather-light devices.

Superior Fatigue & Corrosion Resistance: Unlike metals susceptible to rust and stress fractures, CFRP excels in harsh environments. It withstands corrosive chemicals, salt spray, and cyclic loading far better, ensuring longer lifespan and reduced maintenance for marine components, chemical processing equipment, and critical infrastructure.

Design Freedom & Part Consolidation: CFRP’s moldability allows intricate, aerodynamic, or ergonomic shapes impossible with metals. This enables complex single-piece structures, reducing assembly points, potential failure points, and overall system weight – a key factor in electric vehicle (EV) battery enclosures and drone frames.

Dimensional Stability & Low CTE: CFRP maintains its shape and size remarkably well under thermal stress and mechanical load, crucial for high-precision applications like satellite components, optical benches, and semiconductor manufacturing tools.

Critical Carbon Fiber Reinforced Polymer Applications Driving 2024 Innovation:

Aerospace & Defense: Primary and secondary aircraft structures (wings, fuselages), UAVs, satellites, missile components. CFRP Demand Driver: Fuel efficiency mandates and payload maximization.

High-Performance Automotive & EV: Chassis monocoques, body panels, suspension components, battery trays. CFRP Demand Driver: Range extension for EVs and speed/agility for supercars.

Advanced Robotics & Automation: Robotic arms, end-effectors, gantries, collaborative robot (cobot) frames. CFRP Demand Driver: Need for speed, precision, and payload-to-weight ratio.

Medical Technology: Prosthetics, exoskeletons, MRI/X-ray components (radiolucency), surgical instruments. CFRP Demand Driver: Patient comfort, imaging compatibility, and sterility.

Energy & Industrial: Wind turbine blades, pressure vessels, high-strength piping, tooling. CFRP Demand Driver: Durability in corrosive environments and efficiency gains.

Consumer Electronics & ESD-Sensitive Tech: Laptop chassis, drone arms, wearable tech, semiconductor handling tools, cleanroom equipment. CFRP Demand Driver: Premium feel, durability, weight reduction, AND critical ESD control.

The Hidden Risk: CFRP Conductivity and the ESD Imperative

Standard CFRP’s Achilles’ heel in electronics and sensitive environments is its inherent electrical conductivity. While beneficial for EMI shielding, this conductivity creates a significant Electrostatic Discharge (ESD) hazard. An uncontrolled spark from a conductive CFRP part can instantly destroy sensitive microchips, sensors, or even ignite volatile atmospheres.

Traditional grounding methods are often impractical or insufficient for complex CFRP structures. This is where generic material selection fails, potentially leading to catastrophic failures and costly recalls.

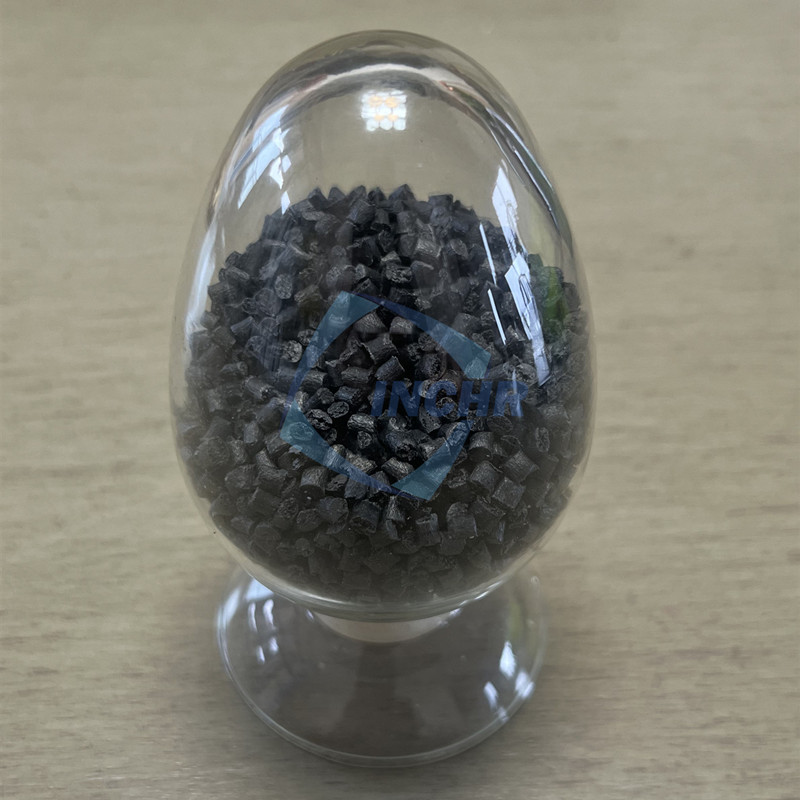

ESD-Safe CFRP: The Essential Evolution for Sensitive Tech

Recognizing this critical need, specialized ESD-Safe Carbon Fiber Reinforced Polymers have emerged. These are engineered composites where the polymer matrix or surface treatment is precisely modified to achieve a controlled surface resistivity, typically within the 10^6 to 10^9 Ohms range (as defined by standards like ANSI/ESD S20.20 or IEC 61340-5-1).

Why ESD-Safe CFRP is Non-Negotiable:

Safe Static Dissipation: Charges bleed off safely and predictably to ground, preventing damaging sparks.

Retained Core Benefits: Maintains the lightweight strength, stiffness, and design freedom of standard CFRP.

Protection for Sensitive Components: Essential for manufacturing, handling, and using semiconductors, PCBs, medical electronics, and explosive environment equipment.

Process Reliability: Prevents costly ESD-related failures during production and in the field.

Selecting the Right CFRP: Key Considerations Beyond Spec Sheets

Choosing CFRP isn’t just about strength and weight. Critical factors include:

ESD Requirements: Is controlled dissipation required? If handling electronics or in explosive zones, ESD-safe variants are mandatory. (This is the core expertise at

inchr-esd.com).Environmental Compatibility: UV resistance? Chemical exposure? Operating temperature range?

Manufacturing Process & Volume: Autoclave (prepreg)? Resin Transfer Molding (RTM)? Compression molding? Influences cost and design complexity.

Thermal & Electrical Properties: Needed for EMI shielding? Thermal conductivity? Coefficient of Thermal Expansion (CTE) matching?

Regulatory Compliance: Meeting industry-specific standards (e.g., FAA, ISO, UL, ESD Association).

Future Trends: Smarter, Greener CFRP

The CFRP evolution continues:

Faster & Cheaper Production: Automation (automated fiber placement, AFP) and out-of-autoclave (OOA) curing are reducing costs.

Thermoplastic CFRP: Offering improved toughness, recyclability, and faster cycle times.

Functional Integration: Embedding sensors (strain, temperature) directly into the composite for “smart” structures.

Sustainability Focus: Development of bio-based resins and improved CFRP recycling technologies (pyrolysis, solvolysis) to address end-of-life challenges.

Hybrid Structures: Intelligent combinations of CFRP with metals or other composites for optimized performance and cost.

Conclusion: Embrace the Lightweight Revolution Responsibly

Carbon Fiber Reinforced Polymer is fundamentally altering engineering possibilities. Its ability to deliver extreme strength with minimal mass unlocks performance gains across aerospace, automotive, robotics, and beyond. However, its inherent conductivity presents a serious ESD risk in critical electronics and volatile settings.

Ignoring this risk is not an option. Specifying ESD-Safe CFRP is essential for reliability and safety in these sensitive applications. By partnering with specialists who deeply understand both the material science and the stringent demands of ESD control (like those at inchr-esd.com), innovators can fully leverage CFRP’s transformative potential while mitigating hidden dangers. The future is lightweight, strong, and smart – make sure it’s also ESD-safe.