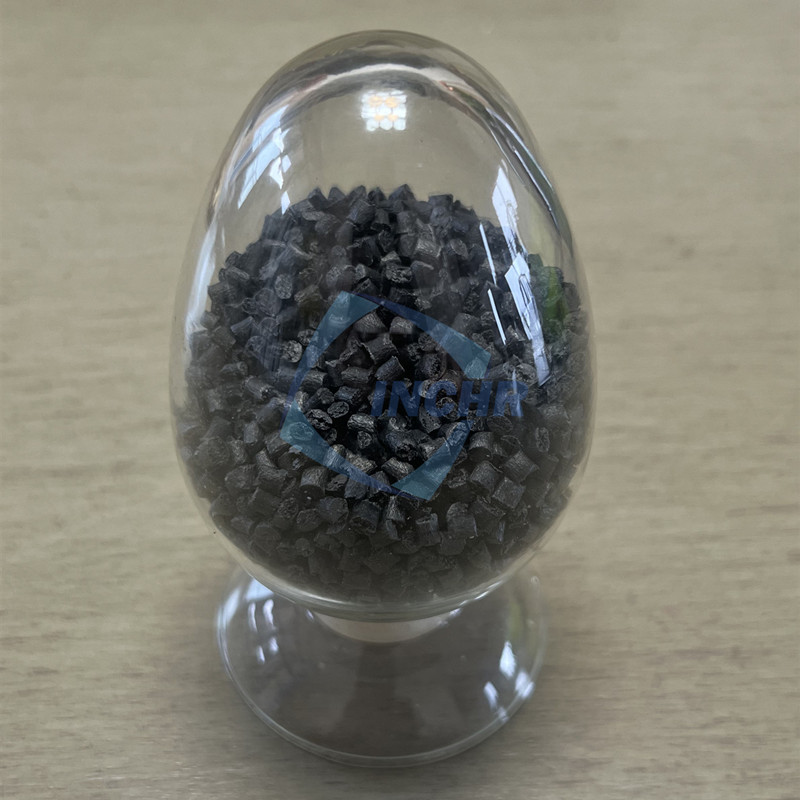

In the relentless pursuit of stronger, lighter, and more efficient materials, Carbon Fiber Reinforced Polymer (CFRP) has emerged as a true game-changer. This advanced composite material, often simply called “carbon fiber composite,” combines the exceptional tensile strength of carbon fibers with the versatility of a polymer matrix (like epoxy). The result? A material that’s transforming industries from aerospace to consumer electronics, especially where lightweight strength and electrostatic discharge (ESD) control are paramount.

Why CFRP Stands Out: Unmatched Strength-to-Weight Ratio

The most celebrated property of CFRP is its incredible strength-to-weight ratio. Pound for pound (or gram for gram), CFRP is significantly stronger and stiffer than traditional metals like steel or aluminum. For example:

CFRP can be up to 10 times stronger than steel while being only a fraction of the weight.

It’s approximately 40% lighter than aluminum while offering comparable or superior strength.

This translates directly into improved performance and efficiency. Vehicles use less fuel, aircraft fly farther, and sporting equipment becomes easier to handle without sacrificing durability.

Beyond Strength: Key Advantages of Carbon Fiber Composites

Corrosion Resistance: Unlike metals, CFRP is highly resistant to corrosion from chemicals, moisture, and salt spray, making it ideal for harsh environments (marine applications, chemical processing).

Fatigue Resistance: CFRP exhibits excellent resistance to material fatigue under cyclic loading, crucial for structural components in aerospace and automotive sectors.

Design Flexibility: CFRP can be molded into highly complex, aerodynamic, or ergonomic shapes that are difficult or impossible to achieve with metal, enabling innovative product design.

Dimensional Stability: It maintains its shape and size exceptionally well under varying temperatures and loads.

Critical Applications Driving Demand for CFRP

Aerospace & Defense: From fuselages and wings (Boeing 787 Dreamliner, Airbus A350) to satellites and drones, CFRP’s weight savings are revolutionary for fuel efficiency and payload capacity.

Automotive & Motorsport: High-performance cars, supercars, and Formula 1 vehicles rely heavily on CFRP for body panels, chassis components, and interiors to enhance speed, handling, and safety. Electric vehicles (EVs) also benefit immensely from the weight reduction, extending battery range.

Sports & Recreation: Bicycles, tennis rackets, golf clubs, hockey sticks, and fishing rods leverage CFRP for unmatched performance, responsiveness, and lightness.

Industrial & Robotics: Robotic arms, automated machinery, and industrial tooling use CFRP for stiffness, precision, and reduced inertia, allowing for faster, more accurate movements.

Medical Devices: Prosthetics, imaging equipment (MRI, CT scanners), and surgical tools benefit from CFRP’s strength, lightness, and radiolucency (it doesn’t obstruct X-rays).

Consumer Electronics: Laptop cases, smartphone chassis, and wearable tech utilize CFRP for premium aesthetics, durability, and minimal weight.

The ESD Factor: Why Material Choice Matters in Sensitive Environments

For applications involving electronics, semiconductors, or explosive atmospheres, controlling electrostatic discharge (ESD) is non-negotiable. Standard carbon fiber composites are inherently conductive. While this conductivity is excellent for applications needing EMI shielding, it poses a significant ESD risk in sensitive environments. An uncontrolled discharge from a conductive CFRP part can easily damage delicate electronic components.

The Solution: ESD-Safe CFRP Options

This is where specialized ESD-Safe Carbon Fiber Composites become essential. These variants are engineered to possess a precisely controlled surface resistance – typically in the range of 10^6 to 10^9 Ohms. This range allows static charges to dissipate safely and gradually to ground, preventing damaging sparks while still offering the core benefits of CFRP (lightweight, strong, rigid).

Choosing the Right CFRP Partner

Selecting CFRP requires careful consideration of your application’s specific needs:

Mechanical Requirements: What strength, stiffness, and impact resistance are needed?

Environmental Conditions: Will it face extreme temperatures, chemicals, or UV exposure?

ESD Requirements: Is controlled static dissipation critical? (This is where

inchr-esd.comspecializes!)Cost & Volume: CFRP can be more expensive than metals; production volume influences the optimal manufacturing process (prepreg, RTM, compression molding).

The Future is Lightweight and Smart

The demand for CFRP continues to surge. Research focuses on enhancing performance, reducing costs (through faster production and recycling methods), and developing “smart” composites with embedded sensors. The integration of sustainability, like using bio-based resins or improving recyclability, is also a major driver.

Conclusion

Carbon Fiber Reinforced Polymer is more than just a high-tech material; it’s an enabler of innovation. Its unique combination of lightweight properties, exceptional strength, and design freedom makes it indispensable for pushing the boundaries of performance across countless industries. When ESD safety is a critical concern, partnering with experts who understand conductive materials and can provide tailored ESD-safe CFRP solutions is vital. By harnessing the power of advanced composites like CFRP, engineers and designers can build lighter, stronger, faster, and safer products for the future.