1.Definition & Composition| Product Catalog

Carbon Fiber Reinforced Nylon (CFRN) is a high-performance composite material combining:

- Matrix: Nylon (Polyamide, PA) – offering excellent processability and wear resistance

- Reinforcement: Carbon fibers – providing superior strength and stiffness

2. Key Material Properties Mechanical Performance

- Tensile strength: >2000 MPa

- Modulus: 150 GPa (vs. 80 MPa for standard nylon)

- Exceptional impact resistance & fatigue performance

Lightweight Advantage

- Density: 1.3–1.5 g/cm³ (1/5 of steel, 1/2 of aluminum)

Thermal Stability

- Service temperature: 120–200℃ (varies by grade)

- Carbon fibers inhibit high-temperature deformation

Environmental Resistance

- Excellent corrosion resistance to seawater/chemicals

- Low water absorption (<50% of standard PA6)

3. Manufacturing Processes

| Method | Application |

|---|---|

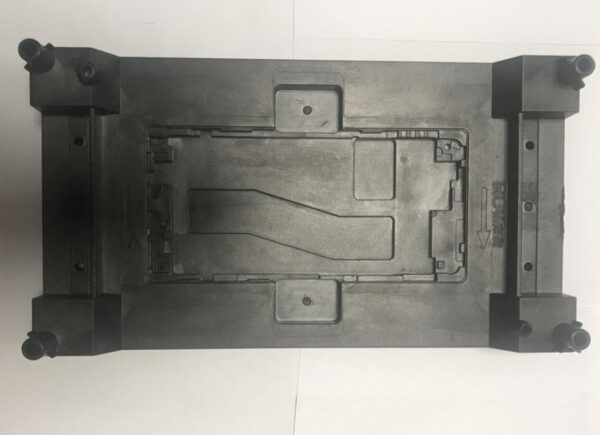

| Short Fiber (Injection/Extrusion) | Complex geometries (gears, housings) |

| Continuous Fiber (Thermoforming) | Aerospace/structural components |

| 3D Printing (PA-CF filaments) | Custom lightweight parts |

4.Industry Applications

- Automotive: Lightweight brackets, EV battery housings (15-30% weight reduction)

- Marine: Corrosion-resistant propellers, piping systems

- Aerospace: UAV wings, satellite components

- Electronics: EMI shielding enclosures (conductive grades)

- Sports: High-end bicycle frames, rackets

5.Carbon Fiber Reinforced Nylon Performance Comparison

| Property | CF/PA | GF/PA | Aluminum 6061 |

|---|---|---|---|

| Density (g/cm³) | 1.3–1.5 | 1.4–1.6 | 2.7 |

| Tensile Strength (MPa) | 200–300 | 150–200 | 270–310 |

| Heat Deflection Temp (°C) | 180–220 | 200–220 | ~250 |

| Corrosion Resistance | Excellent | Good | Requires coating |

6. Conclusion

Carbon Fiber Reinforced Nylon composites revolutionize industrial materials with:

- 55% lighter than aluminum structures

- 3× higher strength vs. standard nylons

- Zero-maintenance corrosion resistance

As production costs decline (30% reduction since 2020), Carbon Fiber Reinforced Nylon adoption is accelerating in automotive, marine, and advanced manufacturing sectors, driving sustainable material innovation.

INCHR was established in Dongguan, China 2012, and it is a professional ESD plastic manufacturer. INCHR offers a wide range of products including permanent antistatic additives, conductive compounds, antistatic compounds, carbon fiber reinforced plastic, ESD masterbatches, and other ESD-modified plastics such as graphene-reinforced plastics. Our R&D team with the support of East China University Of Science And Technology has deep technical accumulation and innovation capabilities. The company is equipped with technologically advanced polymerization equipment, twin-screw granulation units, single-screw unit dyeing workshops, and professional ESD testing equipment, and has passed ISO9001:2008 quality system certification.