Introduction To INCHR@Conductive POM

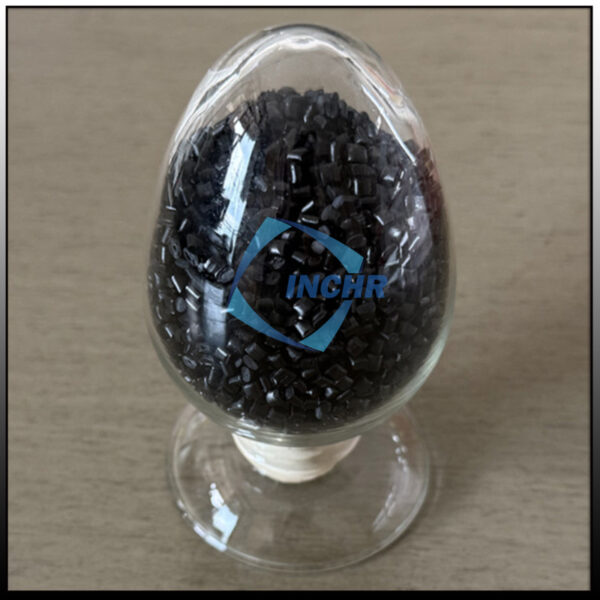

- INCHR@Conductive POM (polyoxymethylene) is composed of POM resin and conductive filler. It is a conductive composite material that can be injection molded or extruded, usually in black granular form.

- By adding specific conductive fillers, such as carbon fiber, carbon nanotubes, etc., POM has excellent conductive properties, which can effectively meet the requirements of material conductivity in the fields of electronics and electrical engineering.

- It retains the high strength, rigidity, and wear resistance of POM itself, has good fatigue resistance and dimensional stability, and can maintain stable physical properties under different environments.

- Good chemical stability, It has good chemical corrosion resistance, can resist the erosion of various chemical substances, and can be used normally in harsh chemical environments.

- Similar to ordinary POM, conductive POM has good fluidity and formability and is easy to make into various complex shapes through various processing methods such as injection molding and extrusion.

Advantages Of INCHR@Conductive POM

- Adjustable performance: The conductive properties and other physical properties of conductive POM can be precisely controlled by adjusting the type and content of conductive fillers according to different application requirements.

- Cost advantage: Compared with some traditional conductive metal materials, conductive POM has a lower cost and lower density, which can reduce the overall cost and weight of the product while ensuring performance.

- Good comprehensive performance: Combining the conductive properties with the mechanical, chemical, and other properties of POM provides a material selection with excellent comprehensive performance, which can meet the use requirements under a variety of complex working conditions.

Applications Of INCHR@Conductive POM

Mechanical Transmission Parts

- Bearing Cage: In the bearing systems of various types of machinery, cages made of conductive POM compound can not only isolate rolling elements and guide the movement of rolling elements, but also reduce friction loss between rolling elements and inner and outer rings of bearings due to their good wear resistance, extend the service life of bearings, and realize the conductive function to prevent static electricity accumulation.

- Chain Guide: In the chain transmission system, the chain guide needs to withstand the friction and pressure of the chain. The chain guide made of conductive POM has excellent wear resistance, which can reduce the friction coefficient between the chain and the guide, reduce wear, reduce energy loss, improve transmission efficiency, and effectively remove static electricity generated during chain movement.

Sports Equipment Field

- Ski Base: Conductive POM compounds can be used for ski bases. Its wear resistance can enable skis to maintain good sliding performance under different snow quality and terrain conditions, reduce wear, and extend the service life of skis. At the same time, its conductive properties help reduce static electricity generated during skiing and improve skiing safety and comfort.

- Bicycle parts: For example, bicycle pedals, chain covers and other parts, conductive POM can withstand friction and pressure during riding with their wear-resistant properties, reduce the wear of parts, improve the overall performance and service life of bicycles, and prevent static electricity from interfering with bicycle electronic equipment.

Textile Machinery Field

- Roller: In textile machinery, rollers are important components for pulling and conveying yarns. Rollers made of conductive POM compounds have good wear resistance and can maintain surface smoothness and precision during long-term high-speed operation and friction with yarns, reducing yarn wear and end breakage rate. At the same time, their conductive properties can prevent yarns from generating static electricity during traction.

- Yarn guide: Yarn guides guide the direction of yarns during the textile process and need to have good wear resistance. Yarn guides made of conductive POM can withstand the friction of yarns, are not prone to wear and scratches, ensure the smooth conveying of yarns, and can promptly remove static electricity generated during yarn movement to avoid the influence of static electricity on the textile process.