Introduction Of Conductive ABS Compound

Introduction Of Conductive ABS Compound

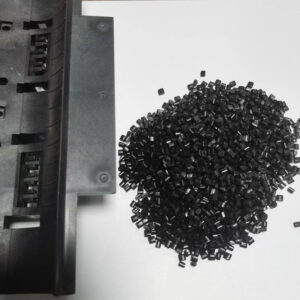

- Conductive ABS compound is a composite material with acrylonitrile-butadiene-styrene (ABS) as the base resin and various conductive fillers added to make it conductive. The base ABS resin has injection molding grade and extrusion grade. The resistance value of the conductive ABS compound is below 10E8 ohms.

- C121 is a conductive ABS compound with stable electrical properties. Its electrical properties remain stable within a certain range of temperature, humidity, and frequency. Under different environmental conditions, the changes in its electrical parameters such as resistivity and surface resistance are relatively small, and it can maintain relatively stable conductive properties. This allows conductive ABS to function reliably in various complex working environments.

- C121H is a high-impact, high-rigidity conductive ABS compound. Although it has a certain amount of fillers, it has better melt fluidity than some other engineering plastics, is easier to fill the mold during processing, and has a relatively short molding cycle, which is conducive to improving production efficiency and reducing production costs.

- Conductive ABS compounds can maintain stable thermal properties within a certain temperature range and are not prone to deformation or decomposition. Its heat deformation temperature is relatively high, generally between 86℃-100℃, and can be increased by about 10℃ after annealing, which can meet the requirements of use in some high-temperature environments.

- Due to the molding shrinkage rate of this compound is relatively small, the dimensional accuracy of the end product is relatively high, which has advantages in the production of precision parts or products with strict dimensional requirements. For example, the shells and parts of some instruments and meters need to use materials with good dimensional stability to ensure the accuracy and reliability of the product.

Common Conductive Fillers In Conductive ABS Compound

Common Conductive Fillers In Conductive ABS Compound

- Carbon black-filled conductive ABS compound: It is one of the most commonly used conductive fillers with relatively low cost and good conductivity. It can form a conductive network in the ABS matrix, making the composite material have a certain conductivity. However, the addition of carbon black may affect the color and mechanical properties of the material, usually turning the material black, and may reduce the mechanical properties of the material such as impact strength.

- Carbon nanotube-filled conductive ABS compound: Carbon nanotubes have high strength and stiffness. Adding them to ABS can play a reinforcing role and improve the mechanical properties of the material such as tensile strength, bending strength, and yield strength. For example, after the appropriate preparation process, the tensile strength, bending strength and other mechanical properties of carbon nanotube-based conductive ABS may be improved by 20% – 50% or even higher than other conductive ABS.

- Carbon fiber-filled conductive ABS compound: It has high strength, high modulus, and good conductivity. The addition of carbon fiber can not only improve the conductivity of ABS but also enhance the mechanical strength and heat resistance of the material. However, the price of carbon fiber is also relatively high, and the processing technology of this level of conductive ABS is relatively demanding, requiring special treatment to make it evenly dispersed in the matrix.

- Metal fibers-filled conductive ABS compound: Such as stainless steel fibers, it has good conductivity and mechanical properties. Metal fibers have a large aspect ratio and are more likely to form a conductive network in ABS, thereby improving the conductive properties of the material. Compared with metal powders, metal fibers have better dispersibility, but they also have the problem of higher costs.

Where Are Conductive ABS Compounds Use in

Where Are Conductive ABS Compounds Use in

- Used in manufacturing the housing, substrate, connector, and other parts of computers, communication equipment, and displays, to prevent static electricity from damaging sensitive components. For example, the use of conductive ABS in the housing of a mobile phone can effectively prevent static electricity accumulation and protect the electronic components inside the mobile phone.

- Used in the fuel system components, dashboards, and interior parts of automobiles to reduce the risk of static electricity sparks and improve the safety performance of automobiles. In addition, the conductive compound can also be used in the electromagnetic shielding components of automobiles to reduce the interference of external electromagnetic signals on automotive electronic equipment.

- Used to manufacture surgical instruments, diagnostic equipment, and medical instrument housings, to reduce the impact of static electricity on equipment and patients. For example, conductive ABS in the housing of an electrocardiograph can avoid the interference of static electricity on electrocardiogram signals and improve the accuracy of diagnosis.