Electrostatic discharge (ESD) silently destroys sensitive electronics daily, costing industries millions. ESD Plastics — engineered materials with controlled electrical resistance — offer the frontline defense. Unlike standard plastics, these specialized polymers safely dissipate static charges, shielding components from catastrophic damage during production, transport, and assembly.

The Science Behind ESD Plastics

ESD Plastics achieve conductivity through:

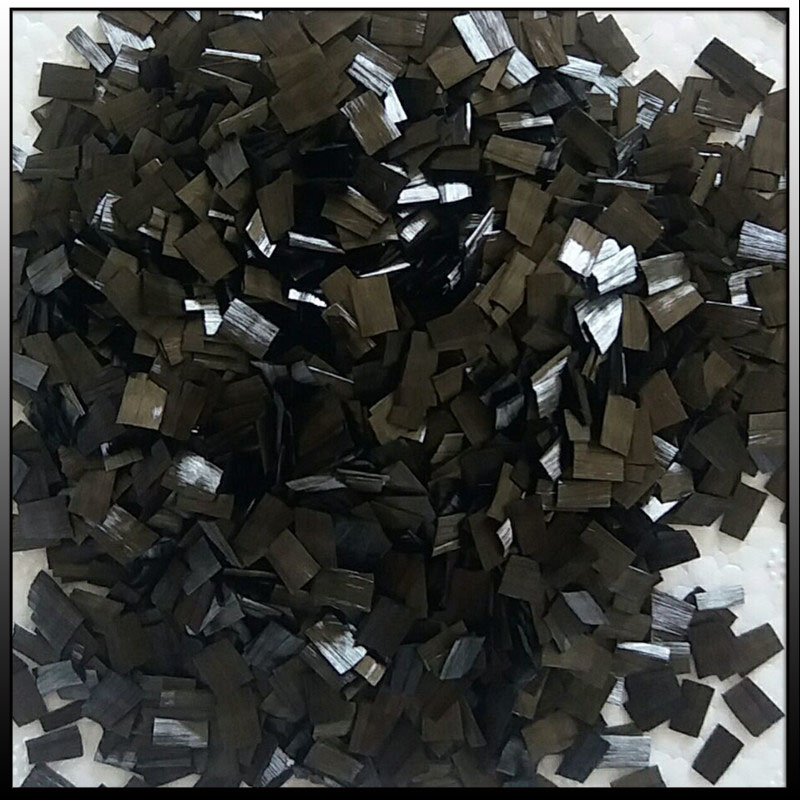

Carbon Loading: Carbon particles create conductive pathways.

Metal Additives: Nickel or copper coatings provide low-resistance surfaces.

Intrinsic Polymers: Permanently static-dissipative compounds (e.g., PET, PE).

Surface resistance typically ranges 10⁴–10¹¹ Ω/sq, balancing charge dissipation with electrical insulation.

Top 5 Benefits Your Operations Can’t Ignore

Zero Component Loss: Protect PCBs, microchips, and sensors from invisible ESD strikes.

Regulatory Compliance: Meet ANSI/ESD S20.20 and IEC 61340 standards effortlessly.

Cost Efficiency: Slash defect rates by 60–90% (industry case studies confirm).

Durability: Withstand chemicals, impacts, and 120°C+ thermal cycles.

Customization: Moldable into trays, housings, fixtures, and IoT device casings.

Applications Redefining Safety

Smart Manufacturing: Robotic arm grips & conveyor belts

Medical Tech: MRI components & surgical tool handles

Aerospace: Avionics shielding & satellite housings

Consumer Electronics: VR headset frames & drone bodies

Choosing the Right ESD Plastics

Avoid costly mismatches:

For high-wear zones (e.g., factory floors), choose glass-filled nylon composites.

Cleanroom environments demand static-dissipative polycarbonate.

Need optical clarity? Opt for acrylic-based ESD blends.

Application of ESD plastics

Esd plastics has multiple applications in various industries such as food production and manufacturing, electrical equipment, different instruments, and many more. In addition, it is used covers, windows, instruments, partitions, keypads, and shields are just some of the various types of media that make up the large family of anti-static plastics. Anti-static plastic materials can be designed with chemical resistance, lightweight, surface hardness, and static dissipation which gives customers their exact customized products. It is widely used in the food and beverage industry and ensures that dust, pollutants, and mites will not be found on products for human consumption. Besides these, it is used in other controlled environments such as within hospital operating rooms. Antistatic plastics are also used in the steel industry to help deaden sound, provide wear and abrasion resistance, and partial protection from scratching in products and finishes.

INCHR-ESD: Your Partner in Static Control

We engineer certified ESD Plastics with:

Guaranteed Resistance Ranges: Third-party tested per ESD STM11.11

ISO 9001-Certified Production: Batch-to-batch consistency

Rapid Prototyping: 2-week custom formulation turnarounds

Upgrade your ESD strategy with INCHR-ESD’s materials — where innovation meets uncompromising protection.

For more information about anti-static plastic applications, please visit our official website for case studies.

https://www.inchr-esd.com/why-esd-plastics-rule-the-electronics-industry/