Carbon fiber reinforced nylon compound can be made injection molded parts through injection molding. The processing technology is simple and can manufacture injection molded parts with complex shapes. Compared with some metal materials, it does not require complex processing technology and equipment, which reduces production costs and processing difficulty.

Unique advantages of carbon fiber reinforced nylon in automotive applications

1. Lightweighting can reduce the weight of the car body

With the improvement of environmental protection requirements and the pursuit of automobile fuel efficiency, automobile manufacturers are actively seeking lightweight materials. Carbon fiber reinforced nylon is lightweight and can significantly reduce the overall weight of the car compared to traditional metal materials. It can effectively reduce the weight of the car, thereby improving fuel efficiency and reducing exhaust emissions. Carbon fiber reinforced nylon compound has a low density, which can effectively reduce the weight of the vehicle body and increase the vehicle’s cruising range while ensuring the structural strength of the vehicle body. Using it instead of traditional metal materials can reduce the weight of the car body by 10%-30%.

2. Excellent mechanical properties improve collision safety

Carbon fiber reinforced nylon combines the high strength of carbon fiber and the toughness of nylon. It has excellent tensile strength and can withstand complex mechanical loads, ensuring the durability and stability of parts under various driving conditions. It has good rigidity and high hardness, can withstand the vibration load of the engine, and is suitable for manufacturing automobile parts that require high mechanical properties. It can quickly cushion the impact in the event of a collision, reducing damage to passengers in the car. At the same time, its good toughness makes the body structure less likely to break after a collision, providing better protection for passengers.

3. Good heat resistance and corrosion resistance increase service life

The temperature of the car engine is very high when working, and the carbon fiber nylon material has excellent heat resistance and can withstand high temperatures without softening and deforming. At the same time, the material has stable chemical properties, is resistant to salt, alkali, and acidic substances, and is not corroded by engine oil, coolant, gasoline, etc., and can be used in the manufacture of parts in harsh environments such as automobile engine compartments.

4. Customized formulas can meet personalized design

The formula can be designed according to the specific specifications and requirements of the end customer, including the content of carbon fiber, the level of nylon resin, conductivity value, etc. Carbon fiber reinforced nylon compounds are easy to process and form, can realize various shapes of auto parts, and meet the growing personalized design needs of the automotive industry.

Application cases of carbon fiber reinforced nylon in the new energy vehicle industry

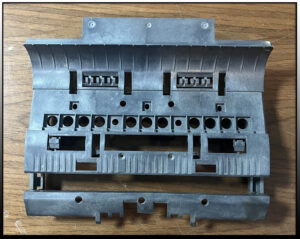

Center console and instrument panel

Carbon fiber reinforced nylon can be made into various complex center console and instrument panel parts through injection molding and other processes. It not only has good dimensional stability and appearance texture but also meets the high strength and wear resistance requirements of automotive interior materials. Compared with traditional plastic interior parts, carbon fiber nylon interior parts are more upscale and beautiful, which helps to improve the interior quality and technological sense of new energy vehicles.

Seat parts

The seat frame, backrest, and other parts of new energy vehicles can use carbon fiber nylon compounds. This material can provide sufficient support for the seat, while reducing the weight of the seat, making it easier for passengers to adjust the seat position and improving riding comfort.

Battery shell

The battery is the core component of new energy vehicles, and its shell needs to have good mechanical strength, high-temperature resistance, corrosion resistance, and insulation. Carbon fiber nylon can meet these requirements and can be used to manufacture battery shells to protect the battery cells and circuit systems inside the battery. In addition, the lightweight characteristics of carbon fiber nylon can also reduce the overall weight of the battery pack.

Motor parts

The motors of new energy vehicles need to work under high-speed rotation and high-temperature environments and have high requirements for heat resistance, wear resistance, and mechanical strength of the materials. The compound can be used to manufacture motor housings, end covers, rotors, and other parts to improve the performance and reliability of the motors. For example, the motor housing made of carbon fiber nylon can better dissipate heat, reduce the operating temperature of the motor, and extend the service life of the motor.

Suspension system

The suspension system is an important part of the automobile chassis and has an important impact on the handling and comfort of the vehicle. Carbon fiber reinforced nylon can be used to manufacture springs, shock absorbers, and other parts of the suspension system. Its high strength and lightweight characteristics can improve the response speed and shock absorption effect of the suspension system, and improve the driving stability and comfort of the vehicle.

Driveshaft

The drive shaft needs to transmit the power of the motor and has high requirements for the strength and stiffness of the material. The carbon fiber reinforced nylon drive shaft has the advantages of light weight, high strength, and small moment of inertia, which can improve the power transmission efficiency and reduce energy loss.