The length of carbon fiber affects many aspects of the performance of carbon fiber reinforced nylon. For example, long carbon fiber can provide better strength and rigidity by forming a more continuous reinforcement phase in the matrix and bearing the load more effectively. Carbon fiber of appropriate length can effectively absorb and disperse impact energy. Short carbon fiber has good dispersion in the matrix but has weak restrictions on shrinkage and a relatively high shrinkage rate. It mainly includes the following aspects:

Mechanical properties

- Strength: Generally speaking, longer carbon fiber can provide a more fiber-matrix interface, and enhance the coupling effect between fiber and nylon matrix, thereby improving the strength of carbon fiber reinforced nylon, such as tensile strength, bending strength, etc. However, when the carbon fiber is too long, the fiber bundle structure will be loose, resulting in a decrease in strength. Therefore, a range of carbon fiber lengths achieves the best strength.

- Rigidity: Long carbon fiber can form a stronger support structure in the nylon matrix, increasing the material’s rigidity. Compared with short carbon fiber, long carbon fiber reinforced nylon has a stronger ability to resist deformation, making the material modulus higher. However, if the carbon fiber is too long, the local rigidity may decrease due to problems such as uneven fiber dispersion.

- Impact performance: Carbon fibers of moderate length can effectively absorb and transmit impact energy, improving the impact resistance of carbon fiber reinforced nylon. When subjected to external force impact, fiber pullout, and fiber breakage are relatively more common, and the impact resistance is relatively weak. However, overly long carbon fibers may reduce the interlacing between fibers, making the stress distribution inside the material uneven, which in turn affects the impact performance.

Processing performance

- Dispersion: Short carbon fibers are relatively easier to disperse in the nylon matrix, which is conducive to the mixing and processing of materials. Due to their long length, long carbon fibers may agglomerate and entangle during processing, resulting in uneven dispersion and increasing processing difficulty.

- Fluidity: Short carbon fibers have little effect on the fluidity of the nylon matrix, making it easier for the material to fill the mold during the molding process, and the surface quality of the molded product is better. Long carbon fibers will reduce the fluidity of the material, and higher molding pressure and temperature may be required to ensure the molding quality of the product.

Dimensional stability

- Shrinkage: The shrinkage of short-length carbon fiber reinforced nylon is relatively high, because the short fiber has a weaker binding effect on the nylon molecules in the matrix, and the material is prone to shrinkage after molding. Long carbon fiber has a strong bonding force with the matrix, which can limit the movement of nylon molecules, thereby reducing the shrinkage of the material and making the product more dimensionally stable.

- Warping: Long carbon fiber easily forms an oriented structure in the nylon matrix, causing the material to warp during the molding process. The orientation of short carbon fiber is relatively weak, and the warping degree of the product is relatively small.

Other properties

- Conductivity: Carbon fiber has good conductivity. The conductive network formed by long carbon fiber in the nylon matrix is more continuous, and the material has better conductivity. Short carbon fiber has fewer contact points due to its short length, and its conductivity is relatively weak.

- Wear resistance: The wear resistance of long-length carbon fiber reinforced nylon is generally better than that of short-length carbon fiber reinforced nylon because long carbon fiber can better bear the load during friction and reduce the wear of the matrix. Moreover, the long carbon fibers have a strong bonding force with the matrix and do not easily fall off during friction, thereby improving the wear resistance of the material.

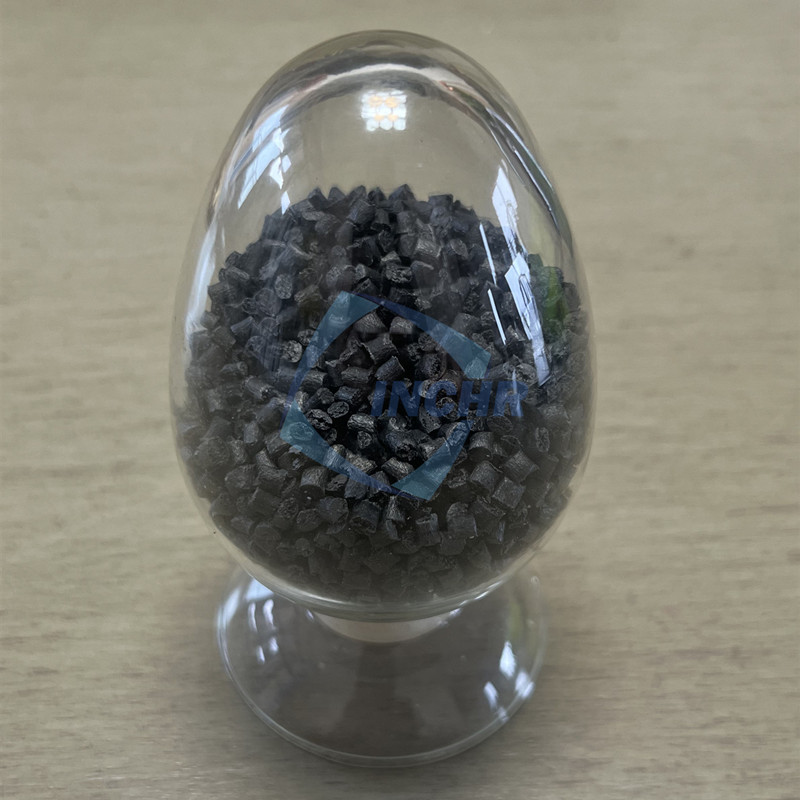

INCHR focuses on the production, sales, and application of carbon fiber reinforced nylon, and has successfully developed carbon fiber composite materials with high strength, high modulus, high temperature resistance, wear resistance, and excellent chemical corrosion resistance. INCHR has rich experience and can design different carbon fiber lengths according to different performance requirements and different application occasions to meet personalized design needs. INCHR@ carbon fiber reinforced nylon material has low specific gravity, which is conducive to improving the fuel efficiency and power performance of automobiles, and provides a better solution for lightweight automobiles and other industries to “replace steel with plastic”. This carbon fiber composite material is also widely used in optoelectronics, sanitary ware, electronic appliances, new energy, and other fields.