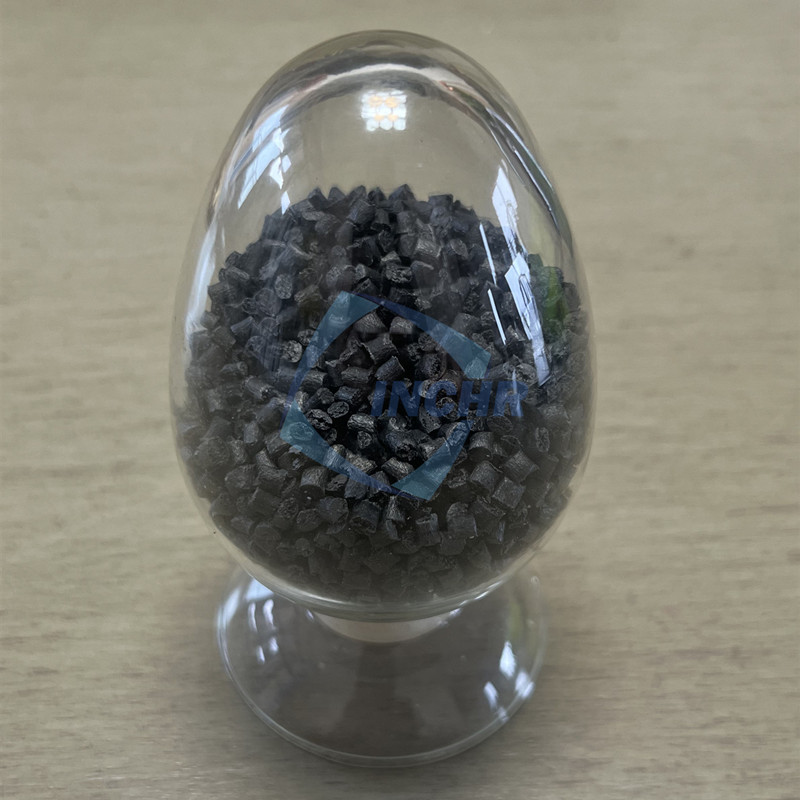

Carbon fiber reinforced plastic injection molding grade is a high-performance composite material. Adding it to plastic can greatly improve the mechanical properties of the material. For example, by adding carbon fiber to nylon (PA) plastic, the tensile strength and bending strength of the carbon fiber reinforced nylon can be greatly improved, and it can be used to manufacture mechanical parts, automotive parts, and other products with high-strength requirements. Carbon fiber reinforced plastic injection molding grade has high-temperature resistance and can easily deform at high temperatures. It is also excellent in fatigue resistance. It can withstand repeated stress loading without being easily damaged, so it is suitable for some structural materials subject to periodic stress. Because of its good conductivity, it can be used in fields such as electrostatic discharge and electromagnetic shielding.

Here are some common injection molding grade carbon fiber reinforced plastics:

Carbon fiber reinforced nylon (PA)

- Nylon 66: Such as BASF C40 NCPA66, a 40% carbon fiber reinforced injection molding grade PA66 material, with excellent wear resistance, self-lubrication, and high mechanical strength, can maintain strong strength and rigidity at high temperatures.

- Nylon 6: Similar to nylon 66 in performance, but with a slightly lower melting point and greater water absorption, carbon fiber reinforcement can improve its strength, rigidity, and heat resistance while improving dimensional stability. It can manufacture mechanical parts, automotive parts, electronic equipment housings, etc.

Carbon fiber reinforced polyphenylene sulfide (PPS)

After carbon fiber reinforcement, its mechanical properties can be further improved. Compared with glass fiber reinforced PPS, it has higher modulus, strength, and lower density. It is often used in aerospace, automobiles, electronic appliances, and other fields.

Mitsubishi Chemical Kyronmax Series

Made from short carbon fibers mixed into the thermoplastic resin, it has extremely high strength and rigidity, with a maximum tensile strength of 383MPa, a specific gravity about 40% lower than aluminum and about 30% lower than magnesium, low anisotropy, and molded products are not easy to warp or twist. The strength loss at the weld line is relatively small. It can be used for drones, firefighters’ LED flashlights, sports and leisure products, automobiles, home appliances, industrial robots, medical devices, and other parts.

Carbon fiber reinforced polyetheretherketone (PEEK)

It has excellent heat resistance, chemical corrosion resistance, mechanical properties, and biocompatibility. Carbon fiber reinforced PEEK composites can be injection molded to produce high-performance structural components, which are often used in aerospace, satellites, military industry, medical, and other fields.

Carbon fiber reinforced polyimide (PI)

PI itself has the characteristics of high strength, high-temperature resistance, chemical corrosion resistance, etc. After carbon fiber reinforcement, its mechanical properties and heat resistance can be further improved. It can be used in aerospace, electronics, and other fields, but the interfacial bonding performance between carbon fiber and PI matrix needs to be improved.

Carbon fiber reinforced polyetherimide (PEI)

PEI is an amorphous high-performance polymer with excellent mechanical properties and electrical insulation. The interface between carbon fiber and PEI matrix can be improved by modification that its performance can be improved. It can be used in aerospace, electronics, and other fields.

Carbon fiber reinforced PPA

PPA is a high-performance polyamide with high rigidity, high modulus, creep resistance, dimensional stability, low water absorption, wear resistance, etc. It has a high long-term working temperature and excellent oil resistance. It has excellent tolerance to various oils such as fuel oil and lubricating oil. It can be widely used in automobiles, communications, medical, machinery, electronics, aerospace, and other fields.