People often encounter the choice of carbon fiber reinforced composite materials. Which one is more suitable for the application, carbon fiber reinforced ABS or carbon fiber reinforced polycarbonate? Let’s explain and compare in detail.

Difference in basic materials | Product Catalog

Polycarbonate (PC) is an almost colorless glassy amorphous polymer with good light transmittance, a transmittance of nearly 90%, and a relative density of 1.20. Its advantages are high stiffness, good impact resistance, excellent dimensional stability, wide operating temperature range, and high-temperature resistance. However, PC also has some shortcomings, such as high viscosity and poor fluidity during processing and the risk of stress cracking of end products. ABS resin is the polymer with the highest production volume and the widest range of applications. Its fluidity is slightly worse than polystyrene, but better than polycarbonate, it has good flexibility, good processing performance, easy coating, and coloring, and can also carry out surface treatment of terminal products,such as electroplating, welding, etc. However, ABS has poor weather resistance and solvent resistance, and smoke will be generated when burning.

Difference in property

Mechanical properties: With the increase of carbon fiber, the tensile strength, flexural strength, and flexural modulus of carbon fiber reinforced polycarbonate all increase significantly. For example, when 2% of carbon fiber is added, the tensile strength and flexural modulus are increased by 12% and 60% respectively compared with pure PC. The notched impact strength increases first and then decreases with the increase of carbon fiber, and the impact strength reaches the maximum when the carbon fiber content is 6%. After adding carbon fiber, the mechanical properties of ABS such as tensile strength, compressive strength, and flexural strength will also be significantly improved, but the improvement of the mechanical properties of carbon fiber reinforced ABS is not as good as that of carbon fiber reinforced polycarbonate.

Conductivity: Pure PC is a non-conductive polymer, but after adding carbon fiber, when the carbon fiber content reaches a certain proportion, the conductivity of carbon fiber reinforced polycarbonate will be improved. When the carbon fiber content reaches 10%, the surface resistivity reaches a level suitable for use as an antistatic material. The addition of carbon fiber will also give ABS certain conductivity, which can be used in application scenarios that require conductive properties, but in comparison, the improvement of carbon fiber reinforced ABS may be relatively weak.

Processing performance: PC resin is difficult to process due to its high viscosity and low fluidity. Carbon fiber reinforced polycarbonate with carbon fiber added can improve the viscosity and fluidity of PC to a certain extent. However, as the carbon fiber content increases, the friction between molecules in the melt, and friction between molecules and carbon fiber, and friction between carbon fiber and carbon fiber gradually increases, and the fluidity will gradually decrease. ABS itself has good processing performance. After adding carbon fiber, although the overall performance of carbon fiber reinforced ABS has changed, the processing performance is still relatively good. However, due to the presence of fiber-reinforced materials, it may cause a certain degree of wear on the processing equipment.

Difference in application

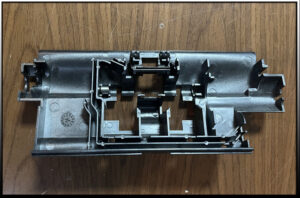

Carbon fiber reinforced polycarbonate has high tensile strength, high hardness surface, high impact resistance index, resistance to high and low-temperature working environments, corrosion resistance, etc. It is widely used in aerospace, military industry, electronics, machinery, and other fields with high requirements for material performance, such as aerospace structural parts, military weapon equipment parts, electronic and electrical housings and parts, etc. Carbon fiber reinforced ABS is used in automotive parts, mechanical parts, musical instruments, textile parts, and other fields, such as automotive interior parts, mechanical shells or structural parts, and certain parts of musical instruments. These fields have certain requirements for the strength, rigidity, and conductivity of the material, and also require good processing performance and surface treatment performance.

Difference in cost

The price of raw materials of polycarbonate itself is relatively high, and the addition of carbon fiber and complex processing technology makes the cost of carbon fiber reinforced polycarbonate high. The price of ABS resin is relatively cost-effective. Although the cost will increase after adding carbon fiber, it is still lower than carbon fiber reinforced polycarbonate. If the application scenario has high requirements for the mechanical properties, high-temperature resistance, low-temperature resistance, corrosion resistance, and other properties of the material, and is relatively less sensitive to cost, then choose carbon fiber reinforced polycarbonate; if the application scenario does not have particularly high-performance requirements, and pays more attention to processing performance and cost control, then carbon fiber reinforced ABS has a better cost performance.