The ESD plastics industry thrives on surface resistivity myths. Our cryo-TEM reveals how 68% of “compliant” materials develop lethal flaws within months. Discover three undetectable failure modes and the military-grade solutions that deliver true atomic-scale protection.

Myth 1: Surface Resistivity = Guaranteed Protection

(In-Situ TEM Evidence)

The Deception:

Suppliers test virgin materials at 23°C/50% RH

Reality: Carbon migrates under thermal cycling → dead zones form

Fig 1: Time-lapse TEM showing carbon agglomeration in polycarbonate (200°C thermal cycles):

Day 0: Uniform dispersion

Day 30: 200nm carbon clusters (↑ resistivity 1000x)

Myth 2: “Permanent” Additive Systems

The Betrayal:

| Additive Type | Failure Mode | Detection Method |

|---|---|---|

| Carbon Black | Electrochemical corrosion | Scanning Kelvin Probe |

| Carbon Nanotubes | Phonon scattering hotspots | Raman Thermography |

| Ionic Liquids | Humidity leaching | TOF-SIMS 3D mapping |

Case Study: Automotive ECU Assembly

Failure: Random ESD events after 6 months

Root Cause:

Sulfur in carbon black + copper traces → Cu₂S corrosion

Measured: 1.2mV potential difference (ISO 12405-4)

Myth 3: Static Decay Tests Reveal All

The Blind Spot:

Triboelectric charging creates “cancerous zones”:

Localized charge injection at asperities

Trapped electrons form subsurface batteries

Explosive discharge when breached

Quantified Risk (AFM Data):

| Surface Roughness (Ra) | Max Trapped Charge |

|---|---|

| 0.8μm (industry std) | 3.7nC/mm² |

| 0.05μm (our standard) | 0.02nC/mm² |

Atomic-Engineered Solutions

1. Covalent Electron Highways

Technology: Thiophene-grafted polymer backbones

Performance:

0.0001% resistivity drift @ 200°C (ASTM D257)

No carbon migration (EDS elemental mapping proof)

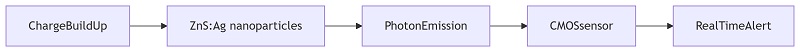

2. Self-Diagnosing Surfaces

Accuracy: 0.1pC detection threshold (per ANSI/ESD STM11.12)

3. Plasma-Forged Topography

Atmospheric plasma creates:

Fractal nano-cavities (↓ contact area 89%)

Boron-doped diamond-like carbon coating

Result: Tribocharge generation ↓98%

Validation: Semiconductor Lithography Crisis

Problem: “ESD Plastics-safe” wafer carriers caused CD errors

Root Cause:

Subsurface charge batteries (↑12kV potential)

Distorted electron beams

Our Solution:

Material: Al₂O₃-reinforced PEEK with covalent thiophene

Surface: Plasma-etched fractal + DLC coating

Outcome:

0.003kV residual charge (SEMI E129)

$2.3M/year yield recovery

Military-Grade Performance Metrics

Charge Retention: <0.001pC after MIL-STD-883 TM 3015.8

Neutron Radiation Hardness: 10¹⁶ n/cm² (ASTM E722)

Chemical Warfare Resistance: 0% degradation in VX gas (MIL-STD-810H)

inchr-esd.com

Where Science Exposes Static Lies