In places like the electronics industry, data centers, and cleanrooms, static electricity is an invisible killer. As the first line of defense, flooring made from conductive PVC compound is a key solution.In modern industrial and production environments, static electricity control is a critical issue that cannot be ignored. Especially in places like the electronics industry, data centers, and operating rooms, static electricity can damage precision equipment, affect product quality, and even pose safety hazards.

Compression-formed conductive PVC compound antistatic flooring is becoming the preferred flooring solution for a growing number of locations due to its excellent performance and environmental friendliness. This article will delve into the application of conductive PVC compound in antistatic flooring.

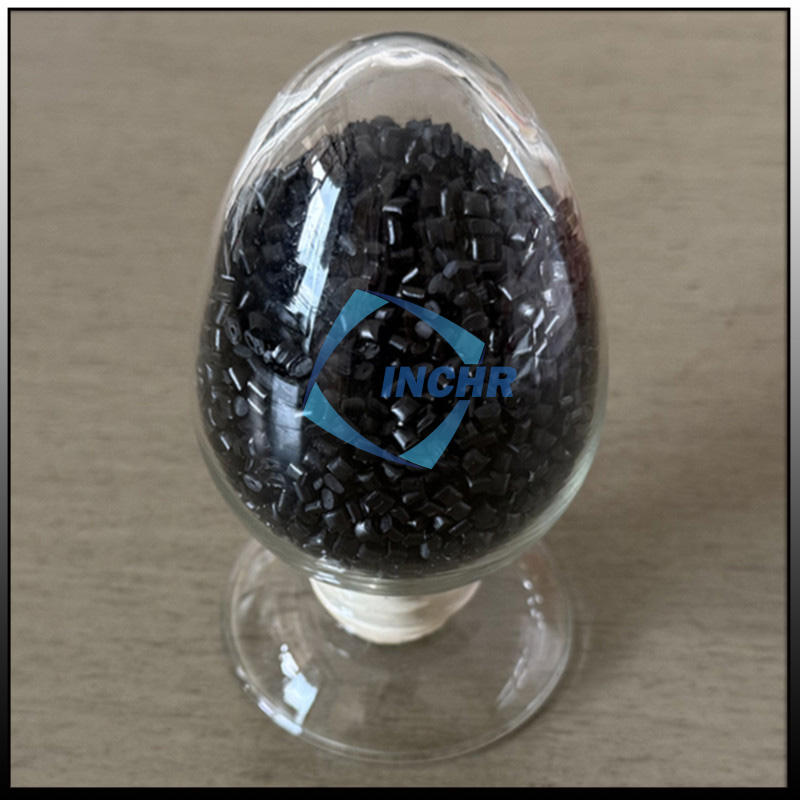

Conductive PVC compound: The core material of antistatic flooring

Conductive PVC compound is a functional material based on polyvinyl chloride (PVC) resin. Conductive materials (such as carbon black, carbon nanotubes, and antistatic agents) and additives are added through a scientifically formulated and processed process. This material not only retains the inherent advantages of PVC, such as wear resistance, corrosion resistance, and flame retardancy, but also provides long-lasting antistatic properties.

Traditional antistatic flooring requires annual cleaning and waxing, resulting in high maintenance costs. New permanent antistatic PVC flooring utilizes a permanent antistatic agent, making it less susceptible to dirt absorption, easier to clean, and maintaining its permanent antistatic properties.

Key features of conductive PVC antistatic flooring

Excellent antistatic performance

The core value of conductive PVC flooring lies in its excellent static control capabilities. Conductive PVC compounds can achieve varying levels of anti-static performance depending on the application requirements. They offer a wide range of surface resistance values and are categorized as follows:

* Conductive: 10²-10⁵ (for electronic shielding wires and underground coal mine equipment)

* Static-dissipative: 10⁶-10⁹ (for anti-static flooring and electronics factories)

* Permanent: 10⁷-10¹⁰ (for packaging and blister packing)

Anti-static flooring used in data centers and electronics factories typically maintains a surface resistance of 10⁶-10⁹Ω. This effectively dissipates static charge, reduces the risk of static accumulation, and creates a suitable environment for precision equipment.

Adjustable hardness

A major advantage of conductive PVC compounds is their wide range of hardness adjustments, allowing for customization based on customer requirements. Flooring products typically have a Shore A hardness of around 85°, ensuring stability and load-bearing capacity while also providing a certain degree of elasticity for a comfortable walking experience.

The adjustable hardness allows conductive PVC flooring to meet the needs of various locations: from industrial plants requiring high hardness to medical facilities requiring moderate softness, suitable PVC anti-static flooring products are available.

Excellent physical and mechanical properties

Conductive PVC anti-static flooring not only has anti-static properties but also inherits many of the excellent properties of PVC:

- High wear resistance: Abrasion loss ≤ 0.02g/cm² (1000 revolutions), long service life

- Corrosion resistance: Resistant to weak acids, weak bases, and most organic solvents

- Excellent flame retardancy: Meets FV-0 flame retardancy standards

- Dimensional stability: Length change upon heating ≤ 0.4%, length change upon water absorption ≤ 0.4%

- Anti-fouling: Smooth, non-porous surface, easy to clean and maintain

Environmentally friendly: Phthalate-free

Traditional PVC materials often face environmental concerns due to the presence of phthalate plasticizers, but new environmentally friendly conductive PVC compounds have addressed this issue.

Environmental Compliance

High-quality conductive PVC compounds use phthalate-free plasticizers and comply with EU ROHS environmental standards. This means the product is free of toxic and hazardous substances, ensuring both human health and environmental safety.

Environmentally Friendly Formula Design

In the material formulation, manufacturers are now using safer alternative plasticizers, such as:

- Environmentally Friendly Plasticizers: Phthalate-free and non-toxic

- Stabilizer Systems: Eco-friendly stabilizers are used to avoid heavy metal contamination

- Conductive Materials: Carbon-based materials (carbon black, carbon nanotubes) are used instead of heavy metal fillers

These environmental improvements make conductive PVC flooring safe for use even in locations where it comes into direct contact with the human body, such as hospitals and laboratories.

Applications of conductive PVC antistatic flooring

From electronics factories to operating rooms, conductive PVC molded anti-static flooring is widely used in the following locations:

- Electronics Industry: Semiconductor manufacturing plants, assembly/manufacturing/R&D /R&D areas in clean electronics production plants

- Telecommunications Industry: Programmable Control Rooms, Computer Rooms, and Data Centers

- Medical: Operating Rooms, Emergency Rooms, and Pharmaceutical and Biotechnology Laboratories

- Industrial Environments: Equipment, pipes, valves, hooks, etc., in underground coal mines

Conclusion

As a professional manufacturer of conductive composite materials, INCHR has consistently provided customers with ESD protection solutions. INCHR@ conductive PVC composite anti-static flooring, manufactured through compression molding, has consistently received acclaim from industry customers for its excellent ESD performance, adjustable physical properties, and environmental advantages. With continuous technological advancements, this functional flooring will continue to evolve, providing safer, more environmentally friendly, and more efficient ESD control solutions for a wide range of industries.