Introduction Of INCHR@Antistatic Masterbatch

Introduction Of INCHR@Antistatic Masterbatch

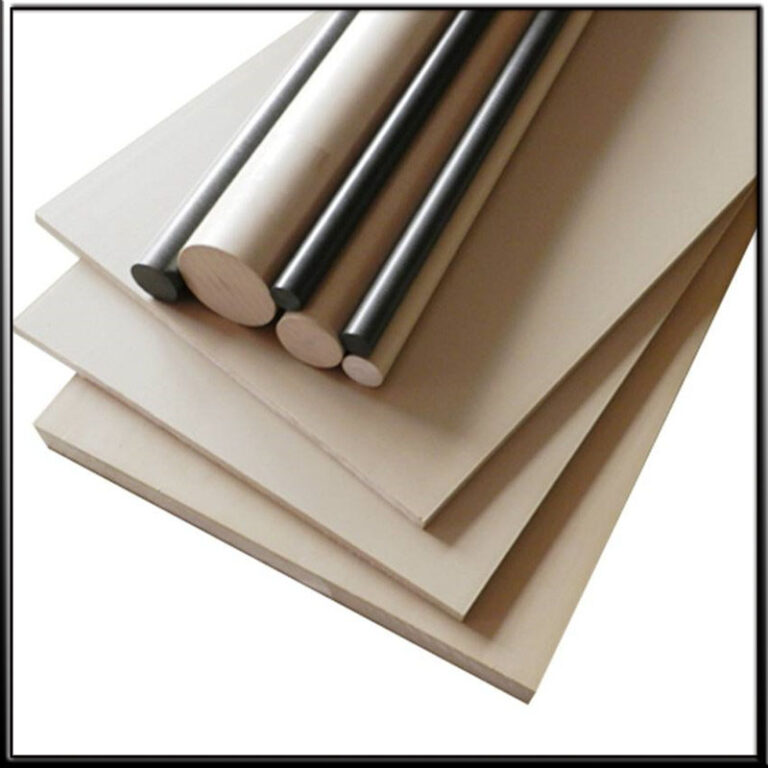

- INCHR@ Antistatic masterbatch is a functional masterbatch with natural antistatic properties. It has the characteristics of permanent antistatic effect, independence from humidity, good compatibility with resin, and little impact on product performance. It is mainly used to solve the static electricity problems of LLDPE film, LDPE protective film, PP stretch film, and HIPS thermoforming sheet.

- INCHR supplies a variety of permanent antistatic masterbatch models, suitable for LLDPE, HDPE, EVA, MABS, HIPS, PP, PVC, PA, and TPU resins. Antistatic masterbatch is usually composed of carriers, antistatic agents, and other additives. The core advantages are low addition amount and the lowest comprehensive cost.

- INCHR@P109 is suitable for various single-layer or three-layer co-extruded films with PE substrates, and has minimal impact on transparency. INCHR@120T is suitable for injection molding and extrusion of transparent ABS substrates.INCHR@PS302AN is suitable for pre-formed sheets of HIPS. It does not affect the impact strength of the sheets, endows the sheets with antistatic properties after addition, and ensures perfect mechanical properties as well.

- Usage: Dry mix with raw materials in a certain proportion. After dry mixing, it can be directly injected, extruded, or blown without compounding, so that the antistatic masterbatch is evenly dispersed in the product. The specific amount of addition needs to be adjusted according to factors such as the type of plastic product, usage requirements, and processing technology. Since INCHR has rich experience in the industry and can also provide customized antistatic masterbatch for special applications.

Features Of INCHR@Antistatic Masterbatch

- Long-lasting and stable antistatic effect: Compared with traditional antistatic agents, the antistatic effect of permanent antistatic masterbatch is more stable and lasting, has no induction period, is not affected by conditions such as wiping and washing, and can be used for up to 5 years. The above can even maintain stable antistatic properties for more than 10 years.

- Not dependent on humidity: Its conductive properties do not depend on air humidity, so it can maintain effective antistatic effects under different humidity conditions, small change in surface resistivity, overcoming the shortcomings of small molecule antistatic materials that are sensitive to humidity.

- Good compatibility: Every antistatic masterbatch is a customizable resin carrier with good compatibility with product resin and can be evenly dispersed in plastic products.

- Little impact on product performance: After addition, it does not affect the processing, color, and mechanical properties of plastic products much.

Applications Of INCHR@Antistatic Masterbatch

Applications Of INCHR@Antistatic Masterbatch

- Application scopes: The antistatic masterbatch can be widely used in a variety of plastic products, such as injection molding, blow molding, blister molding, plastic coating, coating, laminating, blown film, cast film, stretch film, packaging film, plastic sheets, electronic packaging film, bubble bags, flat bags, and stretch film and other products; it can also be used in plastic injection molding, blow molding and sheet fields, and can also be used for anti-static packaging materials, electronic products, dust-free workshop equipment, surface materials and floors for special occasions, flammable and explosive packaging materials, household tools, vacuum cleaner parts, etc.

- Application areas: INCHR provides high-quality transparent antistatic masterbatch for electronic products such as electronic display screens or semiconductor electronic components packaging, which can prevent static electricity accumulation from damaging electronic products while maintaining high transparency and not affecting visual effects. It can be used as packaging materials for industrial products, such as eyeglass lenses, camera lenses, etc., which can not only resist static electricity and prevent dust adsorption, but also maintain good optical transparency. It can be used for medical device shells in the medical field, such as syringes, infusion tubes, etc., to prevent static electricity from causing adverse effects on drugs and patients, and transparent materials are easy to observe.

Will INCHR@Antistatic Masterbatch Migrate?

The antistatic masterbatch produced by INCHR is a polymer material with a long-lasting antistatic effect obtained by reactor polymerization. It can form a percolation network with conductive ability on the plastic surface to play an antistatic role. It is added to the base material by dry mixing and has the advantages of non-migration, durability, strong environmental adaptability, and water resistance.

- Intrinsic dissipative antistatic masterbatch: Taking LLDPE antistatic masterbatch as an example, this type of masterbatch can be added to the plastic during blending, extrusion, or injection molding. It works by using a continuous polymer phase. The ions in it act as charge carriers to dissipate the electrostatic field and will not migrate to the surface of the terminal product in the polymer.

- Carbon quantum dot composite antistatic masterbatch: Taking Nylon antistatic masterbatch as an example, carbon quantum dots are introduced into the antistatic nylon masterbatch obtained by a specific method. The carbon quantum dots are organically combined with the nylon molecular chain and evenly dispersed in the nylon. They have a similar matrix structure to the nylon resin and can form hydrogen bonds. While playing an antistatic role, they will not migrate.

- Thermoplastic polyester elastomer antistatic masterbatch: Taking TPU antistatic masterbatch as an example, as a long-lasting antistatic masterbatch of thermoplastic polyester elastomer TPEE carrier, it has good compatibility with thermoplastic elastomer and other resins. After dosing, it can achieve a permanent antistatic effect without migration, attenuation, and exudates.