Introduction Of INCHR@Antistatic Additive For Nylon

Introduction Of INCHR@Antistatic Additive For Nylon

● Antistatic additive for Nylon is an additive used in nylon resins. Its main function is to reduce the surface resistance of nylon ESD compounds and make them antistatic. During use, it can effectively prevent nylon products from electric shock, sparks, and other problems caused by static electricity accumulation, thereby improving the safety and performance of the products.

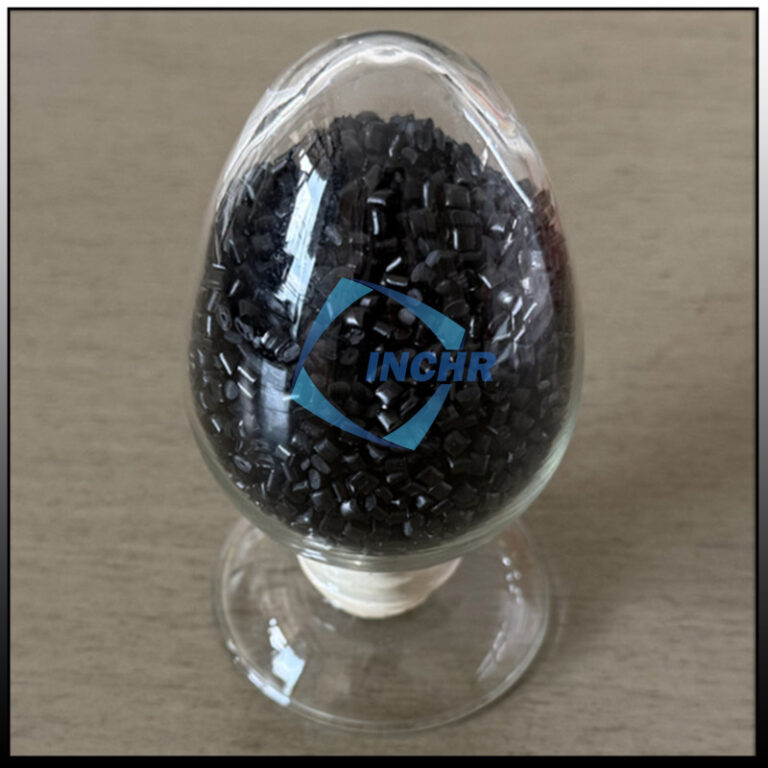

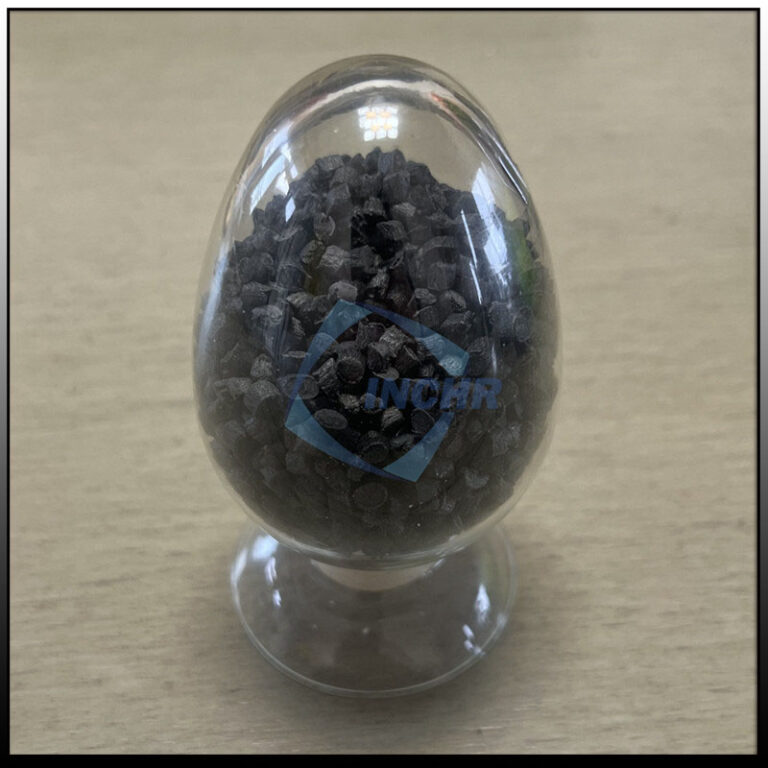

● 92AN is a permanent, non-migrating, internal added type antistatic additive for Nylon that is designed for both anti-dust and preventing electrostatic discharge application. This antistatic additive is immediately functional and imparts long-term anti-static performance, a low influence of relative humidity on the anti-static performance. Suitable for any color formulation. It can be processed by injection, extrusion, and blown after compounding with Nylon. The standard amount of 92AN is between 10 and 20 wt %.

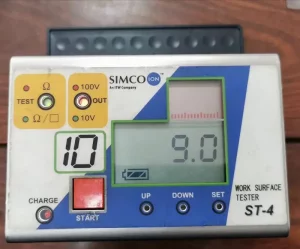

● PA300AN is a permanent antistatic masterbatch that is designed for Nylon 6 single-layer blown film 2.0 mils. It’s a permanent Nylon ESD compound for dry-blend, regularly with 10wt% can achieve 10^10 Ohms on Nylon blown film. It is suitable for antistatic blown films with strong abrasion resistance and good thermal stability for high-quality cleanroom packaging solutions.

In-depth Exploration Of INCHR@Antistatic Masterbatches

The antistatic additive is the key component that gives materials antistatic properties, and INCHR@Antistatic masterbatch is an antistatic agent with an optimized ratio, which is perfectly integrated with various base resins through advanced technology. Compared with the direct use of antistatic additive, antistatic masterbatch has many advantages such as good dispersibility, easy control of the amount of addition, and convenient use. It can ensure that the antistatic agent is evenly distributed in the plastic matrix, stably exerts its antistatic effect, and continuously protects your injection molding and extrusion molding products, effectively avoiding a series of problems such as dust absorption, electric shock, and affecting product performance and appearance caused by static electricity accumulation.

Customized service: Knowing the unique needs of different customers in different application scenarios, INCHR not only provides standardized high-quality antistatic masterbatches based on PP, PE, HIPS, PVC, POM, TPU, PET, MABS and other common materials, but also can quickly prepare customized formulas according to your special applications.

Easy to use: INCHR@Antistatic masterbatch can be put into use by dry mixing, without cumbersome compounding process, which greatly simplifies your production process, saves time and labor costs, and helps you produce efficiently.

Features Of INCHR@Antistatic Additive For Nylon

● Good temperature resistance: It can maintain a stable antistatic effect at a higher temperature, which can meet the use requirements of nylon products in some high-temperature environments. For example, in application scenarios such as nylon parts around automobile engines and nylon shells of electronic and electrical equipment in a heating state, it can still effectively play an antistatic role and will not lose its antistatic function due to temperature increase.

● Long-lasting antistatic effect: The antistatic effect is long-lasting and stable. Unlike some low-molecular antistatic additives, which may gradually migrate, volatilize, or be wiped off during use. Antistatic additives for Nylon can continue to play a stable antistatic role during the service life of nylon products.

● Small impact on material properties: While giving nylon antistatic properties, it has little impact on the basic properties of Nylon ESD compounds such as mechanical properties and processing properties. It will not cause a significant decrease in the mechanical properties of nylon materials such as strength, toughness, and hardness, nor will it have a significant adverse effect on its processing process .

● Good compatibility: Antistatic additives for Nylon and antistatic masterbatch have good compatibility with nylon resin and can be evenly dispersed in nylon materials without phase separation, precipitation, etc. This ensures the uniform distribution of the antistatic agent in nylon products so that all parts of the products can obtain consistent antistatic properties.

Differences Between INCHR@Antistatic Additive Vs Antistatic Masterbatch

Differences Between INCHR@Antistatic Additive Vs Antistatic Masterbatch

● Ingredients: An antistatic additive is a single chemical substance or mixture. Antistatic masterbatch is a mixture made by mixing antistatic additives, carrier resin, compatibilizer, etc.

● Usage: Antistatic additives must be compounded and recommended for compounders. Antistatic masterbatch only needs to be mixed with base resin in a certain proportion, and the addition amount is more accurate and convenient.

● Dosage and dispersion effect: The dosage of antistatic additive is relatively small, and its antistatic effect may be affected by processing technology, conditions, environmental factors, etc. The dosage of antistatic masterbatch is relatively large, and it has better dispersion in resin.

● Cost: Antistatic additive may be relatively low in cost, but considering the loss and control difficulty during the addition process. The dosage of antistatic masterbatch is relatively large, so the cost is relatively high, but due to its convenience and the overall production process, the cost may be more reasonable.