Introduction Of TPU Antistatic Agent

- TPU antistatic agent is an additive that can make TPU and other elastomeric materials have antistatic properties for a long time and stably. It can form a conductive network in the TPU matrix and can be added through conventional processing methods such as extrusion, injection molding, and blow molding.

- Long-lasting and stable: TPU antistatic agent can maintain the antistatic effect throughout the entire use cycle of the TPU material, and will not significantly reduce the performance due to the passage of time, changes in the use environment, etc.

- Not affected by humidity: Unlike some ordinary antistatic agents, TPU antistatic agents can effectively play an antistatic role in dry or humid environments.

- Good compatibility: It has good compatibility with TPU, TPE, and TPV. After dosing, it has little effect on the mechanical properties, optical properties, processing properties, etc. of TPU, and can maintain the original characteristics of TPU.

Applications Of TPU Antistatic Agent

- Medical device industry: Surgical instruments, medical equipment shells, etc., to prevent static electricity from interfering with electronic components and sensitive parts of medical devices. Various catheters used in medical treatment, such as urinary catheters and infusion tubes, can reduce static electricity adsorption and prevent bacteria and dirt from adhering. There are also protective gloves and protective clothing to prevent static electricity from causing discomfort or safety hazards to medical staff and patients.

- Electronic products industry: The shells of electronic products such as mobile phones, tablets, laptops, and televisions often use materials with TPU antistatic agents added to prevent static electricity from damaging the internal precision electronic components.

- Packaging industry: TPU antistatic films for food packaging, electronic component packaging, cosmetic packaging, etc., to prevent static electricity from adsorbing dust and impurities and keep the inside of the packaging clean.

- Sports equipment: TPU end products with anti-slip and wear-resistant properties, such as sports shoes and sports protective gear, improve the performance and comfort of the product and reduce the adverse effects of static electricity.

- Industrial parts: The shells, pipes, seals, casters, etc. of industrial equipment, to prevent static electricity from affecting equipment operation and product quality.

How To Prevent TPU Antistatic Agents From Exudating

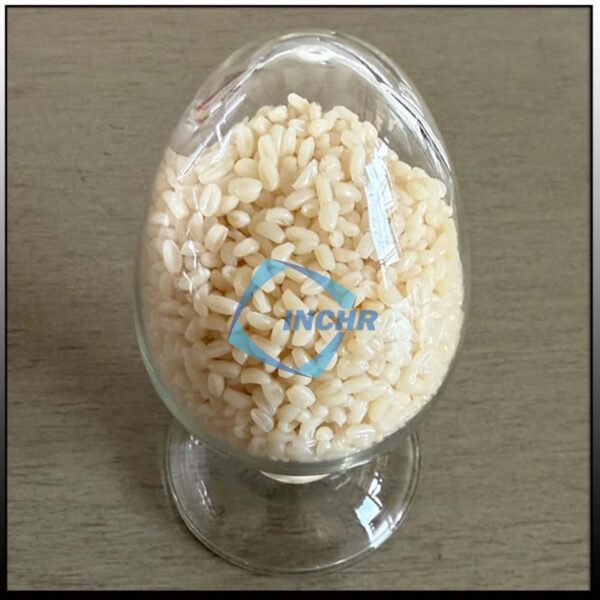

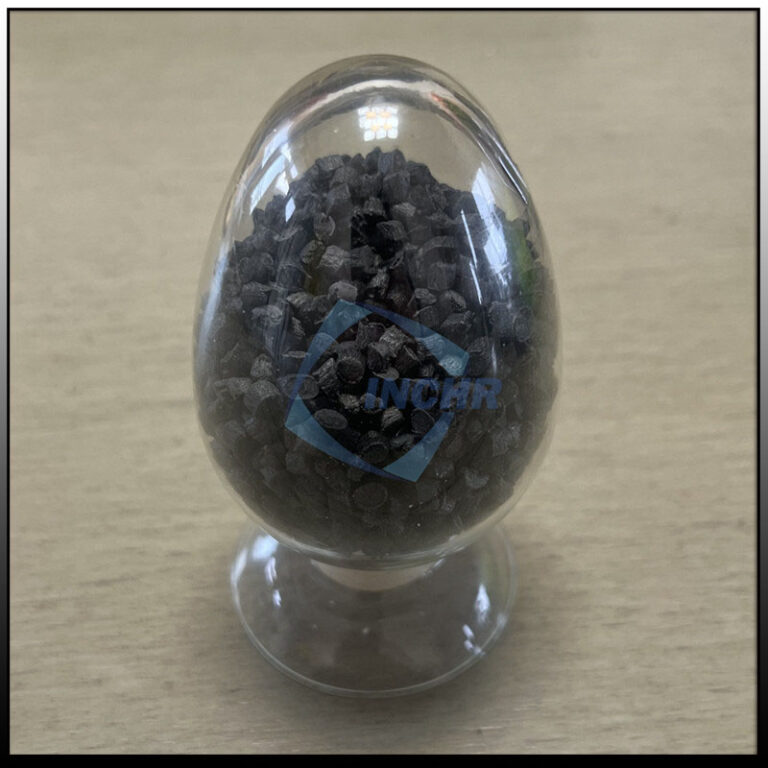

INCHR@ TPU antistatic agent is a long-lasting polyether and polyester block copolymer with a molecular structure of alternating polar segments and amphiphilic segments. It has good compatibility with substrates such as TPU, forms a core-shell structure in the material, and does not need to migrate to the surface to play a role, thus avoiding exudation. In addition to the factors of the antistatic agent itself, The following factors can be controlled to prevent surface exudation.

- Reasonable processing formula design: Fully consider the compatibility of the permanent antistatic agent with the TPU substrate and the interaction between the components, so that the antistatic agent is evenly and stably dispersed in the TPU. For example, select a matching antistatic agent according to the polarity and other characteristics of TPU.

- Accurate processing temperature control: Strictly control the temperature during processing to avoid too high or too low. Too high a temperature may cause the permanent antistatic agent to decompose or migrate excessively, and too low a temperature may cause uneven dispersion, which may cause exudation problems.

- Sufficient stirring and mixing: The stirring and mixing process is crucial for the dispersion of antistatic agents in TPU. Fully and evenly stirred can make the antistatic agent fully dissolved or dispersed in the TPU matrix, reducing the exudation caused by excessive local concentration.

- Use of special chemical additives: If there are no chemical substances that can react chemically with the permanent antistatic agent in the use environment, the antistatic agent can remain stable and is not easy to exudate due to material changes caused by chemical reactions.